Safety precautions

Always read this section before use.

Pneumatic components: Warning and Cautions

Design/selection

DANGER

Do not use this product for flammable fluids.

Working fluids

WARNING

This product cannot be used as a business

meter.

Do not use this product for commercial

transactions as it is not compliant with the

Measurement Act. Intended applications include

industrial sensors.

For fluids other than the applicable fluid, the

accuracy is a reference value.

Use dry gas which does not contain corrosive

elements such as chlorine, sulfur or acids, and

which is clean and does not contain dust or oil

mist.

Depending on the fluid, retaining the fluid

for long periods could adversely affect the

performance. Do not seal the fluid in the pipe for

long periods of time.

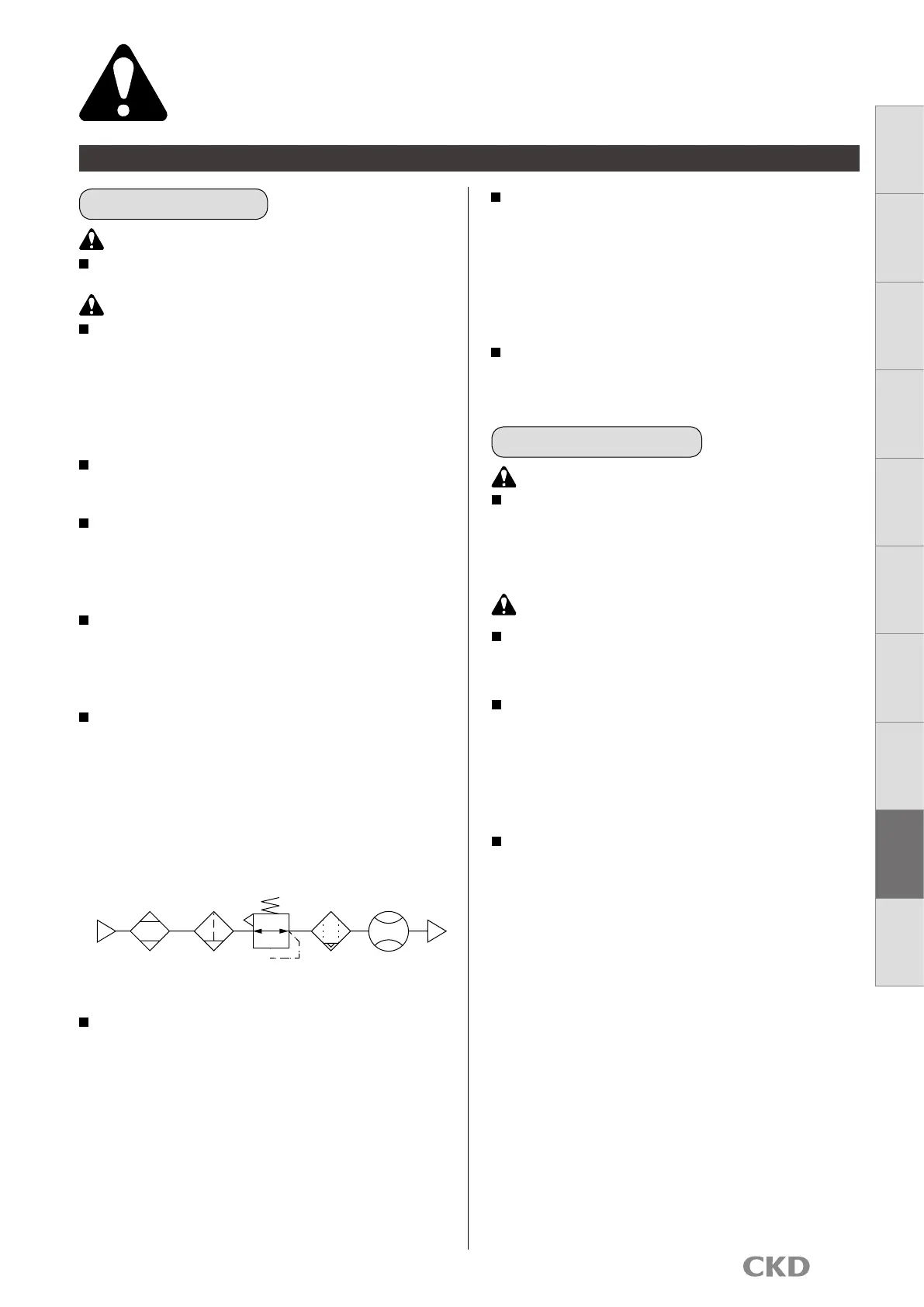

When using compressed air, use clean air that

complies with JIS B 8392-1: 2012 Class 1.1.1

to 1.6.2. Compressed air from the compressor

contains drainage (water, oil oxide, foreign

matter, etc.). So install a filter, air dryer, and oil

mist filter (micro alescer) on the primary side

(upstream side) of the sensor. The sensor's

mesh rectifies flow in the pipe. It does not filter

out foreign matter, so provide a filter.

Working pressure/flow rate range

Applications exceeding the max. working

pressure and specified flow rate range may

result in faults. Use this product only within

the specified range. If energized in a vacuum

state of −0.07 MPa or less, the sensor's heat

dissipation will suffer, leading to degradation of

the sensor.

DANGER

Working environment

Explosion-proof environments

WARNING

Corrosive environments

Do not use this product in an atmosphere

containing corrosive gases such as sulfur dioxide.

Ambient/fluid temperatures

Use ambient temperature/fluid temperature from

0 to 50°C within specified range.

Even if the temperature is within the specified

range, do not use this product if the ambient

temperature and fluid temperature could

suddenly change and cause dew to condense.

Drip-proof environments

The degree of protection of this product is

equivalent to IP40. Do not install this product

where water, salt, dust, or swarf is present or in

a pressurized or depressurized environment. The

product cannot be used with large temperature

variations or high temperature/humidity since

condensation may occur inside the body.

Never use this product in an explosive gas

atmosphere. The structure is not explosion-

proof, and explosions or fires could occur.

[Recommended values]

When using a valve on the primary side of

the sensor, use only valves with oil-prohibited

specifications. This sensor could malfunction or

fail if exposed to splattering grease, oil, etc. As

friction powder may be generated depending on

the valve, mount a filter to prevent the powder

from entering the sensor.

When using liquefied gas such as carbon

dioxide, always vaporize it first. If liquefied gas

enters the product, it may result in failure.

Source

pressure

Air dryer Filter Regulator

Oil mist

Filter

(Micro alescer)

Flow rate sensor

FSM Series

44

LCD display Bar display

IO

-

Link

Internal

structure

Separate

display

Technical

data

Operating

method

Optional

products

Safety

precautions

Related

products

Loading...

Loading...