Si30-408 REFNET Piping

Introduction 19

5.2 For Refrigerant Piping

Guideline for Tightening Flare Nut (When No Torque Wrench is Available.)

Notes: 1. When pipe jointing with flare nut, use both open-ended spanner and a torque wrench.

2. If no torque wrench is available, refer to the following item 3 as a guide.

3. In the work of tightening flare nut, there should be a spot where the tightening torque

suddenly increases. Thereafter, tighten further with tightening angle shown in above list.

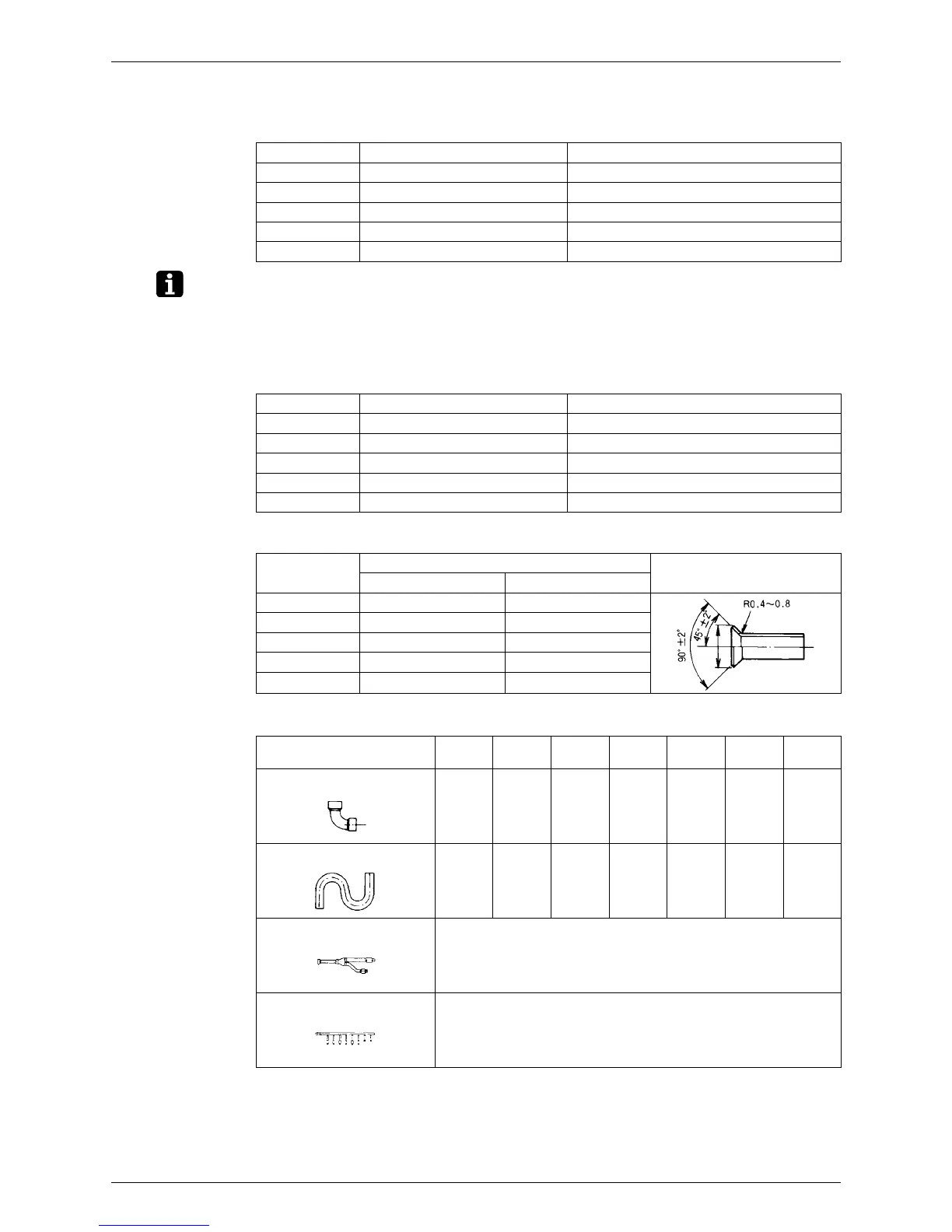

Bending Radius in Pipe and Flare Tightening Torque

Processing Dimension for Flare Section

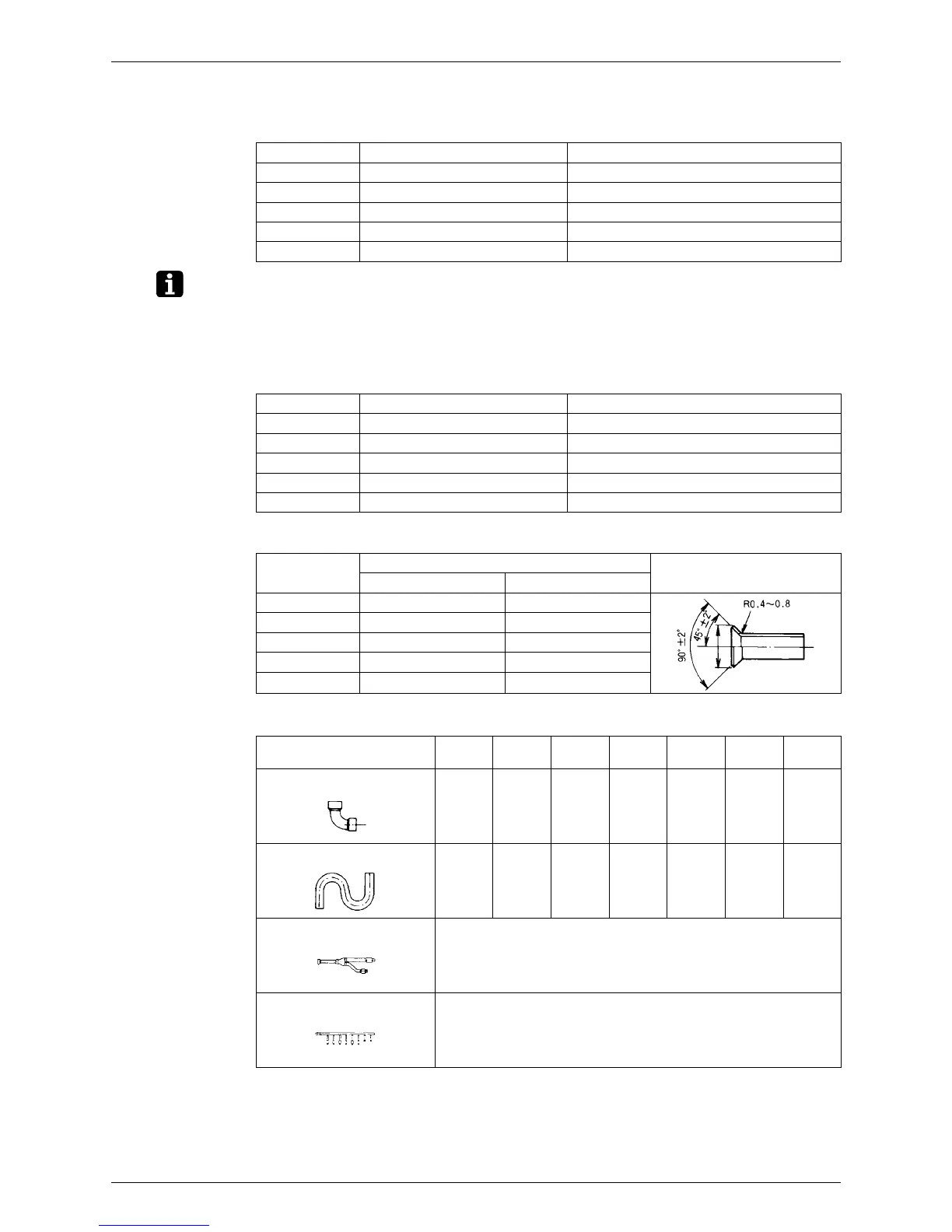

Calculation List on Equivalent Length of Joint (For Reference)

Unit: m

Piping size Tightening angle (guideline) Recommended arm length of tool

φ6.4 60º ~ 90º Approximately 150mm

φ9.5 60º ~ 90º Approximately 200mm

φ12.7 30º ~ 60º Approximately 250mm

φ15.9 30º ~ 60º Approximately 300mm

φ19.1 20º ~ 35º Approximately 450mm

Piping size Bending radius Tightening torque (N·cm)

φ6.4 30 to 40 mm 1420 ~ 1720

φ9.5 30 to 40 mm 3270 ~ 3990

φ12.7 40 to 60 mm 4950 ~ 6030

φ15.9 40 to 60 mm 6180 ~ 7540

φ19.1 — 9720 ~ 11860

Piping size

Dimension-A

Flared shape

R22, R407C For R410A

φ6.4 8.6 ~ 9.0 8.7 ~ 9.1

φ9.5 12.6 ~ 13.0 12.8 ~ 13.2

φ12.7 15.8 ~ 16.2 16.2 ~ 16.6

φ15.9 19.0 ~ 19.4 19.3 ~ 19.7

φ19.1 23.3 ~ 23.7 (24)

Pipe diameter

Type

φ6.4 φ9.5 φ12.7 φ15.9 φ19.1 φ25.4 φ31.8

L joint

0.16 0.18 0.20 0.25 0.35 0.45 0.55

Trap bend

1.41.31.52.02.43.44.0

REFNET joint

0.5

REFNET header

1.0

Loading...

Loading...