How to replace the Compressor Si30-408

228 Appendix

6. How to replace the Compressor

For RSXYP to M:

(1) Collect the refrigerant by using refrigerant

recovery unit.

(Since the setting on outdoor unit PCB is required

for refrigerant recovery, refer to the warning plate

"Precautions in service work" attached on the

switch box cover.)

(2) Remove the sound insulator mat covering the

faulty compressor, and disconnect the power

cable from terminal board of the compressor.

(3) Disconnect the brazing sections of suction pipe

and discharge pipe by using brazing torch after

the refrigerant has been collected completely.

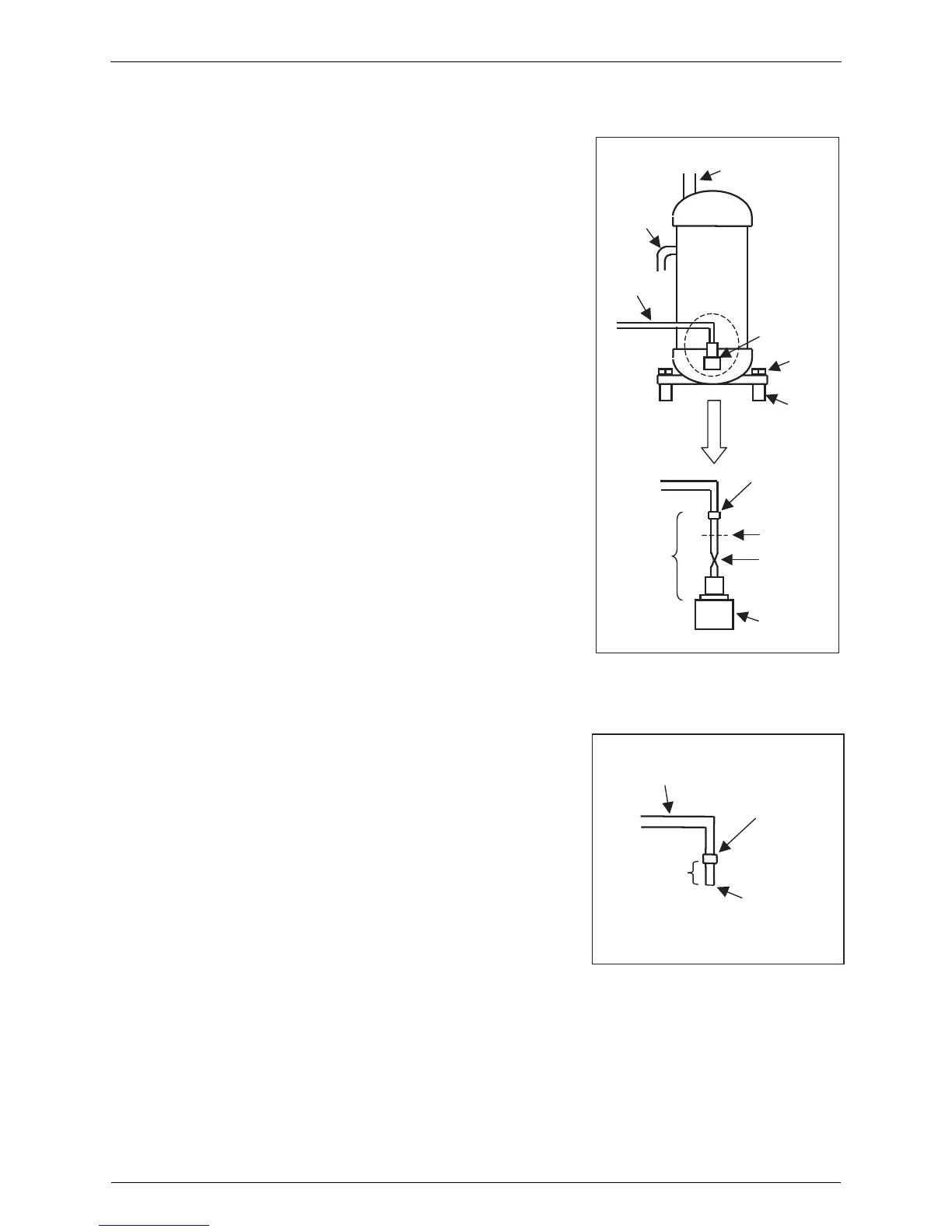

(4) Pinch the oil pressure equalizing pipe of the faulty

compressor at the lower part of the brazed joint as

shown in figure 1, and cut it between the pinched

section and brazed joint in order to prevent

residual oil from discharging.

(5) Remove three bolts at cushion rubber section to

take out the faulty compressor outside the unit.

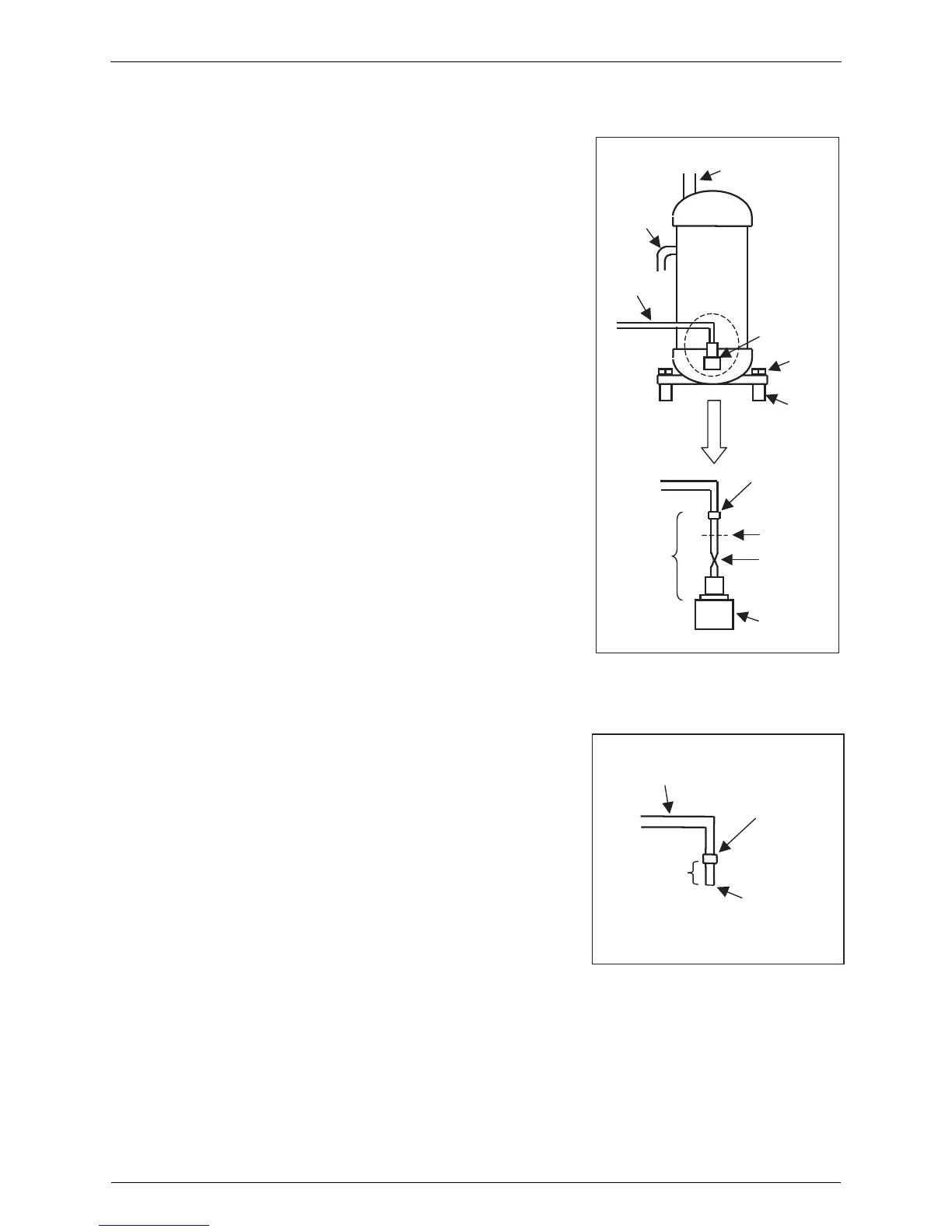

(6) Check that no oil remains in the oil pressure

equalizing pipe as shown in figure 2, then remove

the cut pipe from the brazed joint with brazing

torch.

(7) Install the new compressor in the unit.

(Be sure to insert the cushion rubbers before

tightening the fixing bolts of compressor.)

(8) Remove the rubber caps put on the suction and

discharge pipe of the new compressor to release

the sealing nitrogen gas.

(Take note that oil may spout due to the pipe

inside pressure if the plug put on the equalizing

seat is removed before removing of rubber cap.)

(9) Remove the plug put on the equalizing seat of the

new compressor.

(10) Install the outlet pipe on the equalizing seat of the

new compressor.

(11) Braze the equalizing seat outlet pipe to the oil

pressure equalizing pipe with brazing torch.

* Since an O-ring is put in the equalizing seat, be

sure to maintain the parts around O-ring in cool.

(12) Braze the suction and discharge pipe with brazing

torch to the compressor.

(13) Conduct air tight test to check the piping system is

free from leakage.

(14) Connect power cable to the terminal board of

compressor and cover the compressor with sound

insulator mat.

(15) Conduct vacuum drying.

(Since the setting on outdoor unit PCB is required for vacuum drying, refer to the warning

plate “Precautions in service work” attached on the switch box cover.)

(16) Charge refrigerant after the completion of vacuum drying, and check the function of

compressor with cooling or heating operation.

Suction pipe

Discharge pipe

INV

compressor

Oil equalizing

pipe

Equalizing seat

Bolts

Cushion

rubber

Brazed section

2. Cut

1. Pinch

Equalizing seat outlet pipe

Equalizing seat

Fig. 1

Oil pressure equalizing pipe

Brazed section

Cut section

Remove

* Check that no oil remains in the oil pressure

equalizing pipe before removing of the cut

pipe.

Fig. 2

Loading...

Loading...