Si30-408 Points of Refrigerant Control of VRV System

Basic Information 25

3.2 Heating Operation

Subject to change of the number of operation (thermostat-on) units, capacity, air flow rate,

suction temperature, of indoor units

Load on total system changes.

Loads on every indoor unit are different.

Compressor

Capacity Control

In order to maintain the heating capacity against condenser capacity and load fluctuation, based

on the pressure detected by high-pressure sensor control (Pc), compressor capacity is so

controlled to put the high pressure equivalent saturation temperature (condensing temperature

= Tc) close to target value.

Superheated

Degree Control of

Outdoor

Electronic

Expansion Valve

In order to maintain the superheated degree in evaporator, based on the pressure detected by

the low pressure sensor (Te) and the temperature detected by the thermistor of suction pipe,

outdoor electronic expansion valve is so controlled as to put superheated degree at evaporator

outlet close to target value.

• Superheated degree SH = (outdoor suction pipe temperature – outdoor evaporating

temperature)

Subcooled

Degree Control of

Indoor Electronic

Expansion Valve

In order to distribute proper refrigerant flow rate in spite of different loads on every indoor unit,

based on the pressure detected by the high pressure sensor of outdoor unit (Tc) and the

temperature detected by the thermistor of indoor liquid pipes, indoor electronic expansion valve

is so controlled as to put subcooled degree at condenser outlet close to target value.

• Subcooled degree SC = (outdoor condensing temperature – indoor liquid pipe

temperature)

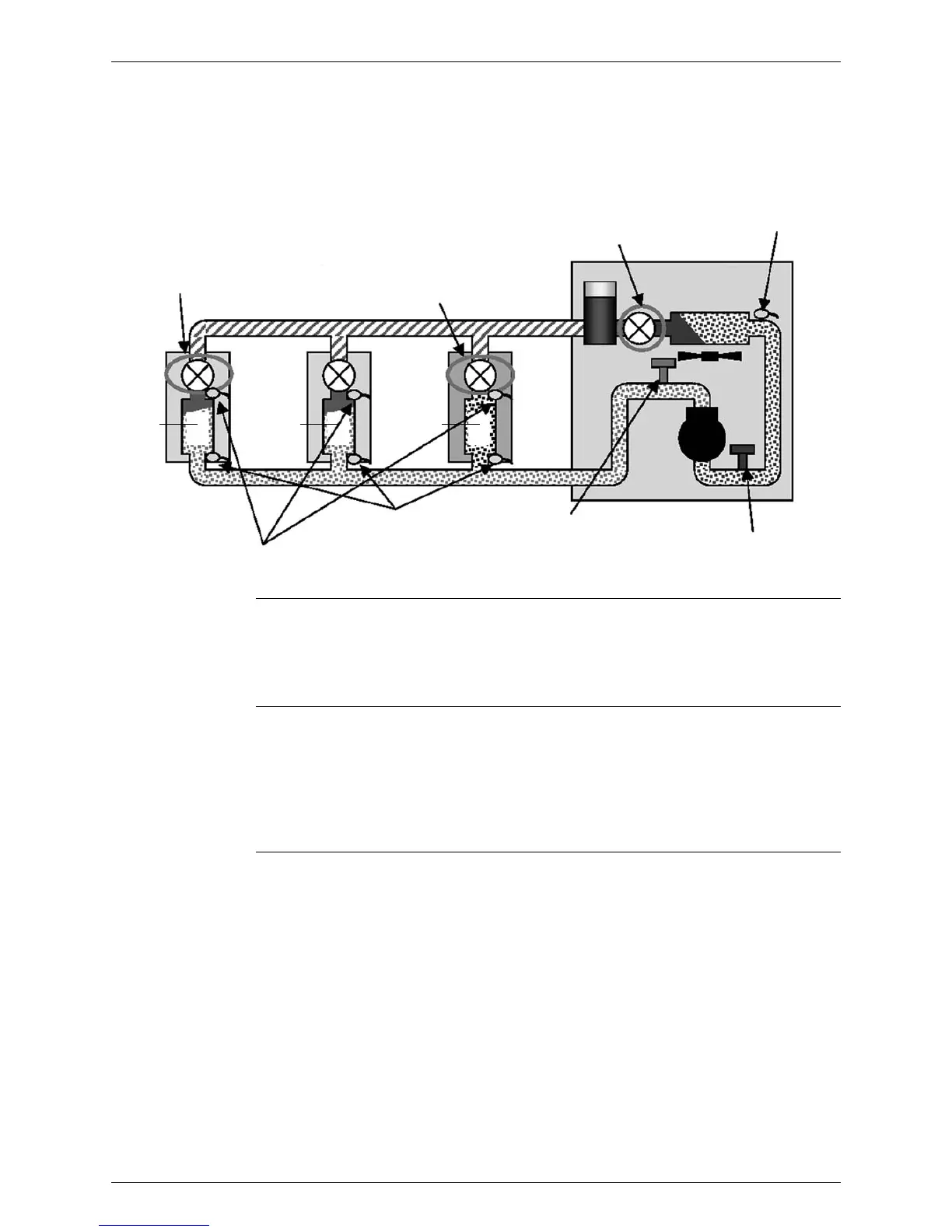

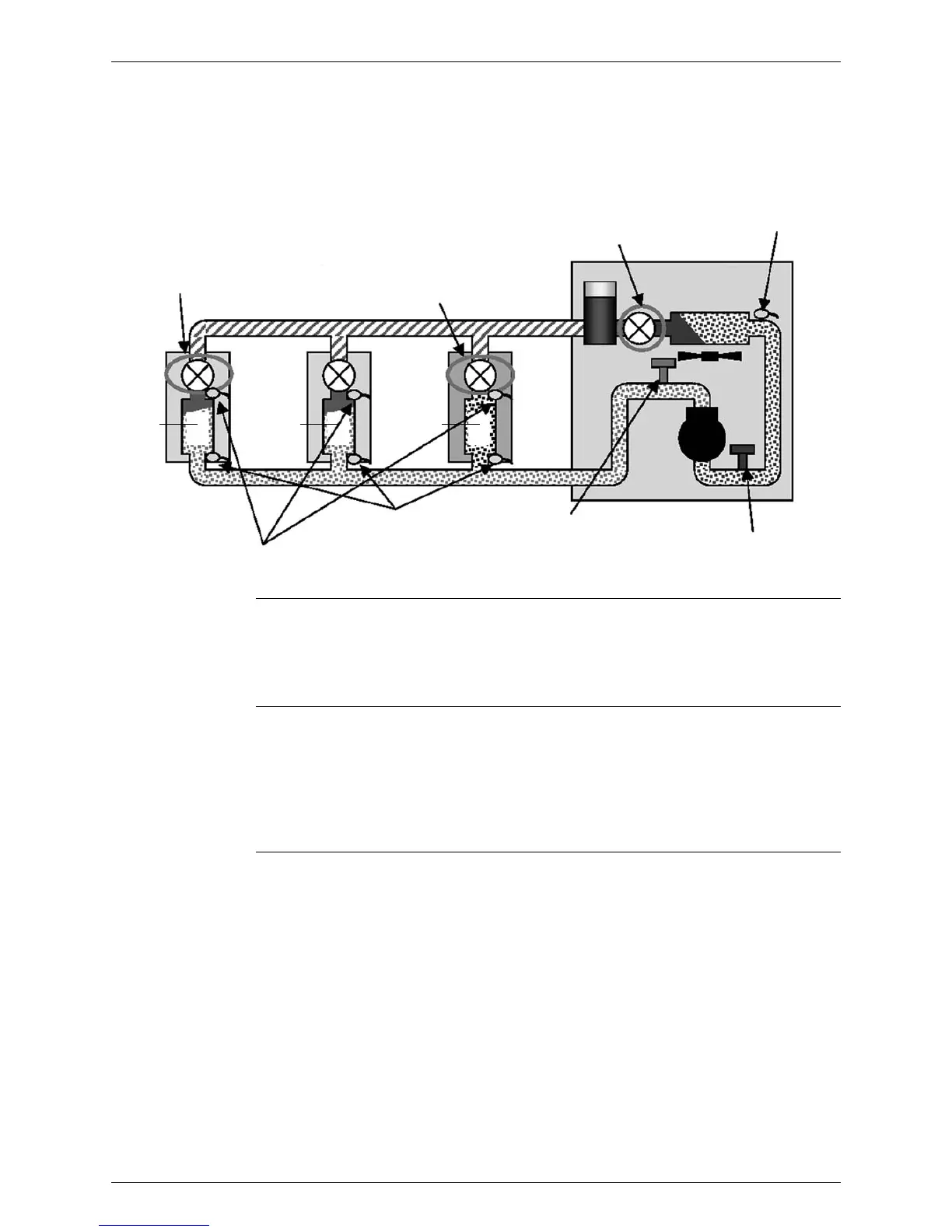

Subcooled degree control

Superheated degree control

Suction pipe thermistor

Heating

Compressor

Low pressure sensor

Receiver

High pressure sensor

Gas pipe thermistor

Liquid pipe thermistor

As to stopping unit and thermostat-off unit, electronic

expansion valve should be minute-closed (approx.

200 pls) in order to prevent refrigerant from collection

in indoor heat exchanger.

Operation

Operation Stop

Loading...

Loading...