VLT

®

5000 SyncPos option

MG.10.J4.02 – VLT is a registered Danfoss trade mark

30

■■

■■

■ Execute the test run program

Now connect the motor to the VLT, make sure that

the motor can turn completely freely.

NB!

The motor must be provided with an [EMER-

GENCY STOP] button.

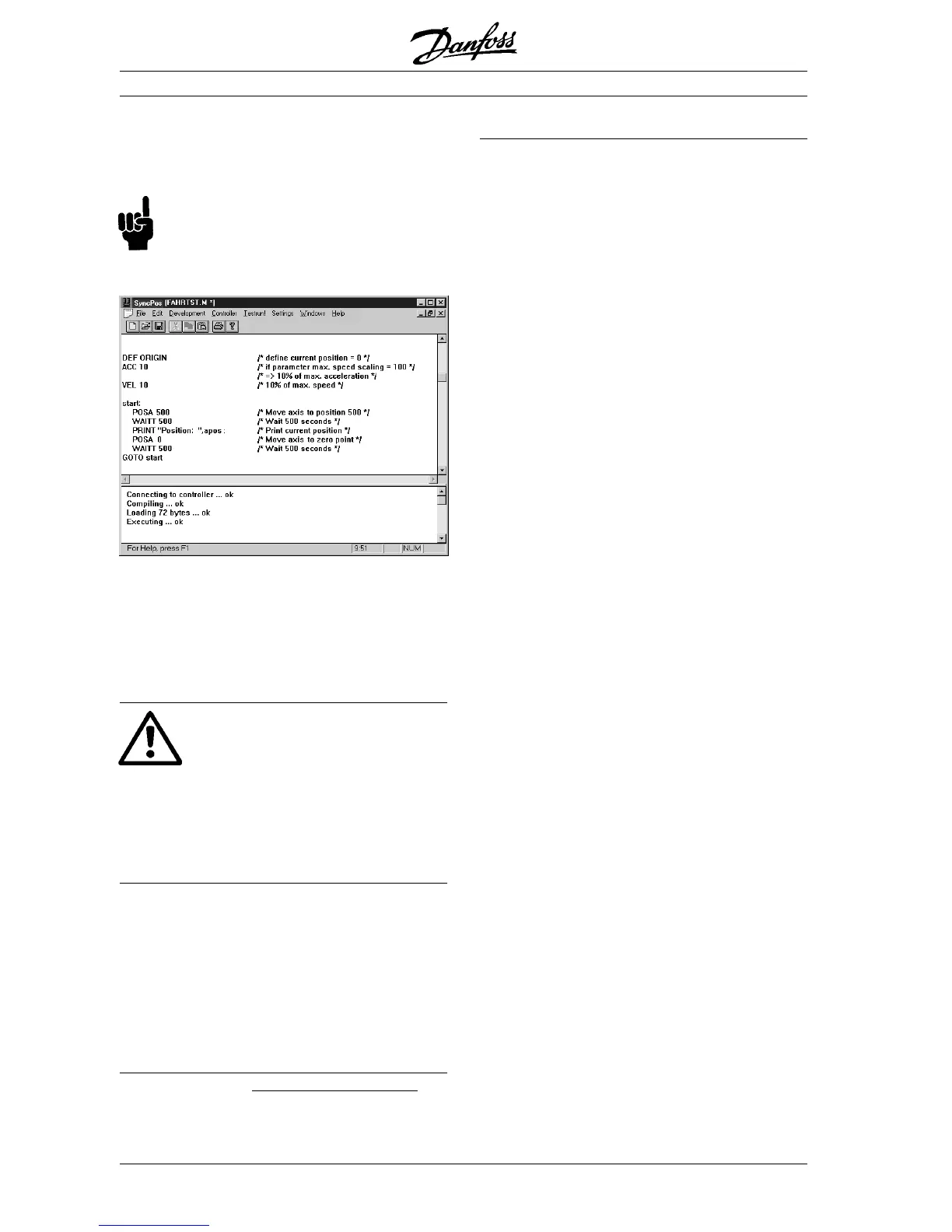

Click on "FILE" and "OPEN"

the file

Fahrtst.m Fahrtst.m

Fahrtst.m Fahrtst.m

Fahrtst.m.

Click on "DEVELOPMENT" and start the test pro-

gram with "EXECUTE"

or

[F5].

The test is successful if the motor runs slowly back

and forth and position 500 is registered.

End the test with [ESC] and "CLOSE" the "FILE".

If the motor sets off uncontrolled or vibrates heavily

NB!

Turn off the motor immediately with the

EMERGENCY STOP button if it vibrates

heavily or sets off uncontrolled.

If the motor sets off uncontrolled, but the encoder

test previously was successful, then decrease the

Proportional factor Proportional factor

Proportional factor Proportional factor

Proportional factor (parameter 702). (See Optimi-

zing the PID controller)

If the motor doesn’t move

If the motor doesn’t move at all, then the proportio-

nal factor of the PID filter is probably too low or

the VLT has not been enabled.

Check the VLT enable (terminal 27 = 24 V) and

check that the VLT wasn't stopped via the LCP

(flashing display). Then increase the

ProportionalProportional

ProportionalProportional

Proportional

factor factor

factor factor

factor (parameter 702). (See Optimizing the PID

controller)

If the motor vibrates heavily …

… then you have to

optimize the PID controller and

to adjust the other parameters of the controller:

reduce either the

Proportional factor Proportional factor

Proportional factor Proportional factor

Proportional factor KPROP (11)

or increase the

Derivative factor Derivative factor

Derivative factor Derivative factor

Derivative factor KDER (12).

If a "tolerated position error is exceeded" is reported

If the drive stops due to a “tolerated position error is

exceeded” message it is possible to determine

whether the drive was rotating in the wrong

direction by comparing the curves of the set and

actual values.

Check the connections of the motor or encoder. If

the connections are correct, then it is necessary to

increase the

TT

TT

T

olerated position error olerated position error

olerated position error olerated position error

olerated position error POSERR (15).

(See Optimizing the PID controller)

Starting the SyncPos option step-by-step

Loading...

Loading...