35

MG.10.J4.02 – VLT is a registered Danfoss trade mark

VLT

®

5000 SyncPos option

8. If you are using the integration part of the PID

controller, remember to reduce the KILIM as

much as possible (without losing the KINT-

effect of course) in order to reduce oscillations

and overshoot as much as possible.

9. Reduce the BANDWIDTH as much as possib-

le. With a properly optimized open-loop con-

trol BANDWIDTH could be reduced to as little

as 6 or 12 %.

10. Set the POSERR (15) parameter back to nor-

mal e.g. 20000.

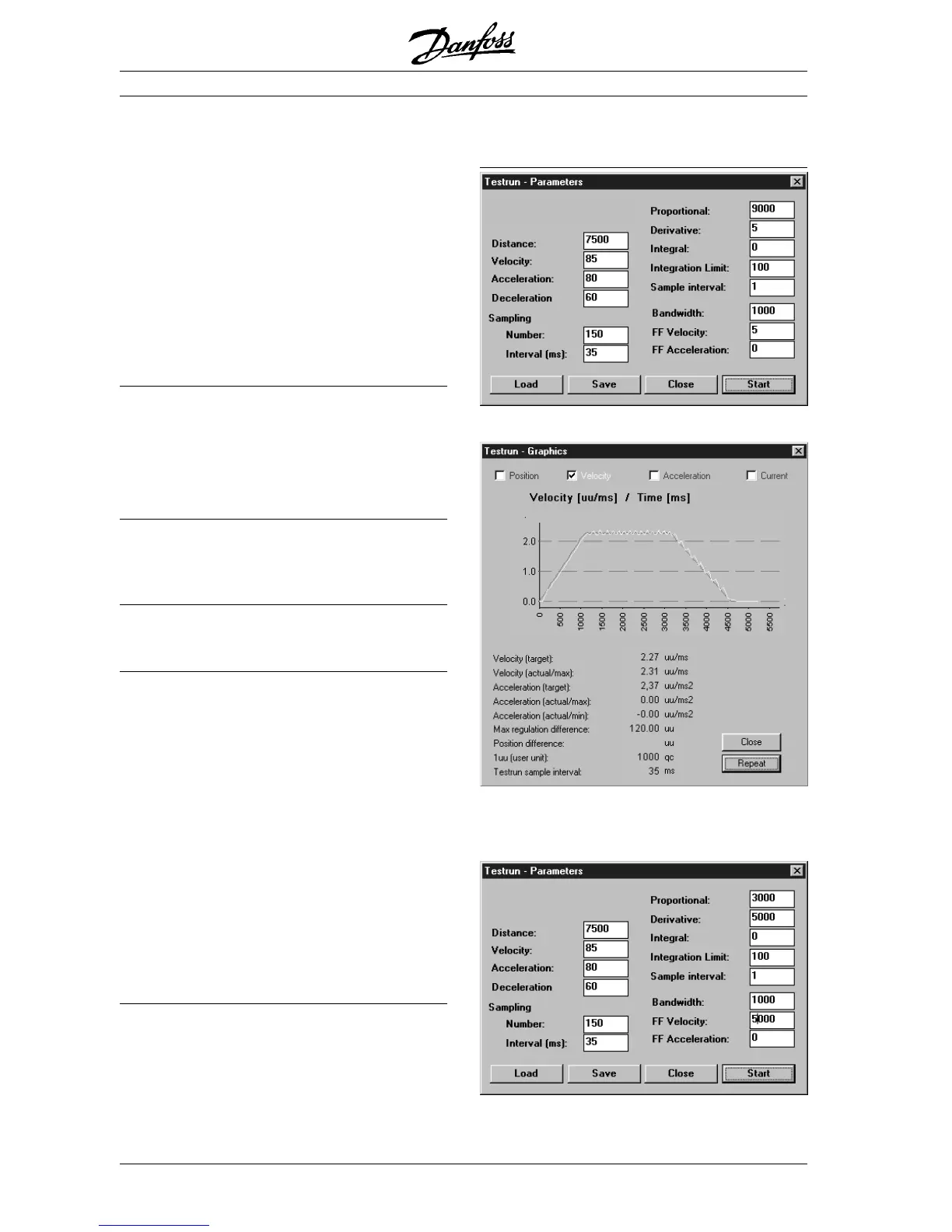

"TEST PARAMETER" → "SAVE"

Once you have concluded the "TESTRUN"

→→

→→

→

"SAVE"

the new parameters as the user parameters.

Thus, these parameters are saved in the controller

and in the future will be used for all programs.

■ What to do if...

... there is a tendency towards instability

In the event of a strong tendency towards instabi-

lity reduce the proportional and derivative factors

again, or reset the integral factor.

... stationary precision is required

If stationary precision is required then you must

increase the integral factor.

... the tolerated position error is exceeded

If the test run is constantly interrupted with the

message “position error” set the parameter for the

TT

TT

T

olerated position errorolerated position error

olerated position errorolerated position error

olerated position error POSERR (15) – within the

tolerable limits– as large as possible.

If the position error occur during the acceleration

phase that suggests that the set acceleration can-

not be achieved under the existing load conditions.

Increase the

TT

TT

T

olerated position errorolerated position error

olerated position errorolerated position error

olerated position error POSERR (15)

or determine a maximum acceleration suitable for

the entire system.

If position error do not occur until after the accele-

ration phase and they can be delayed but not eli-

minated by increasing the

TT

TT

T

olerated position errorolerated position error

olerated position errorolerated position error

olerated position error

,,

,,

,

this suggests that the maximum velocity (rpm)

chosen is too high. Determine a maximum velocity

suitable for the entire system.

.. the maximum acceleration is not achieved

In general, the technical data for a drive are only va-

lid for a freely rotating axle end. If the drive is carrying

a load the maximum acceleration is reduced.

The theoretical maximum acceleration will also not

be achieved if, for example, the PID controller out-

put is too small or the VLT/motor is not sized cor-

rectly and therefore does not provide enough

energy for peak consumption during acceleration.

■■

■■

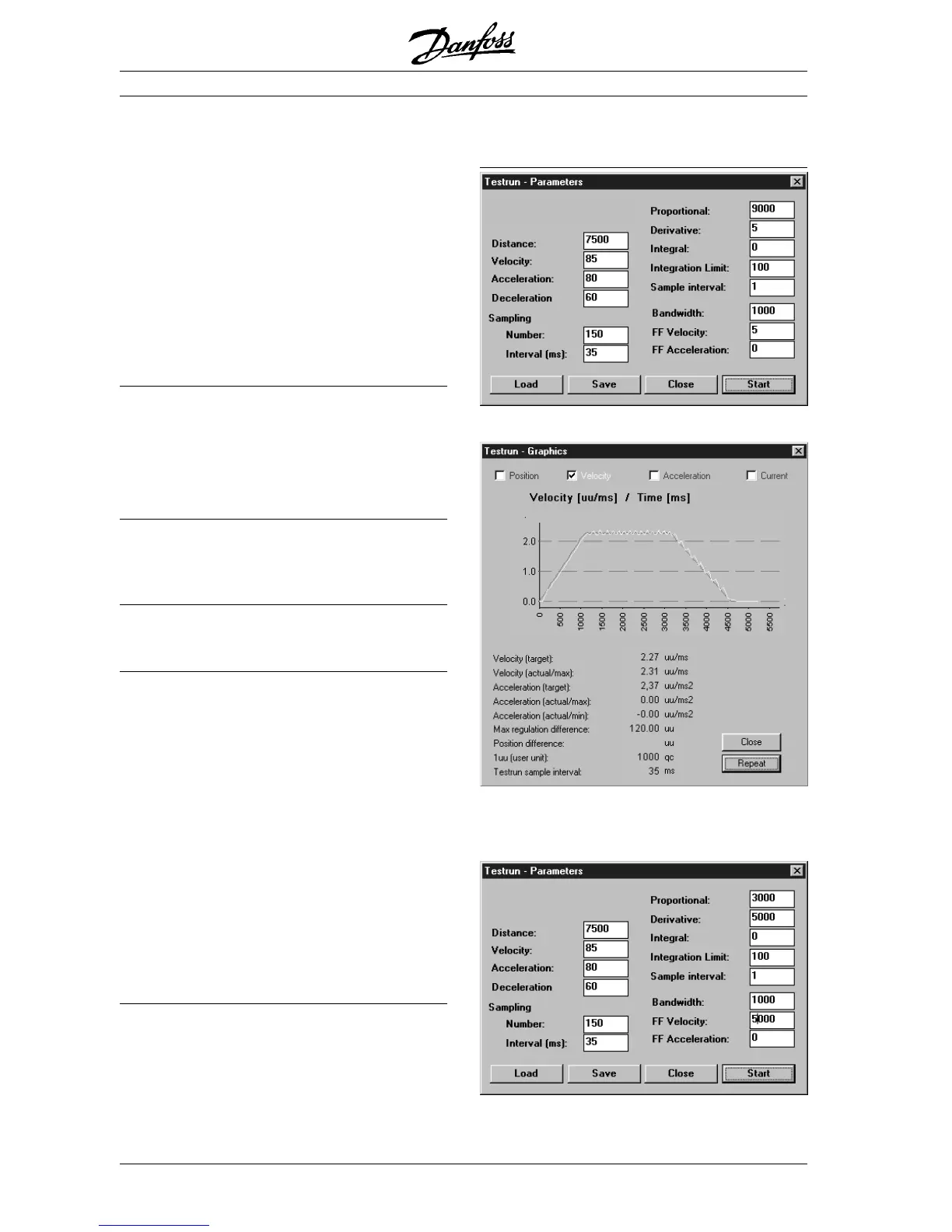

■ Examples of control optimization

Dampening of vibrations

The drive vibrates:

By increasing the

Derivative factorDerivative factor

Derivative factorDerivative factor

Derivative factor to 5000 and

reducing the

Proportional factor Proportional factor

Proportional factor Proportional factor

Proportional factor to 3000 vibration

during running and braking is lessened

..

..

.

Optimizing the PID controller

Loading...

Loading...