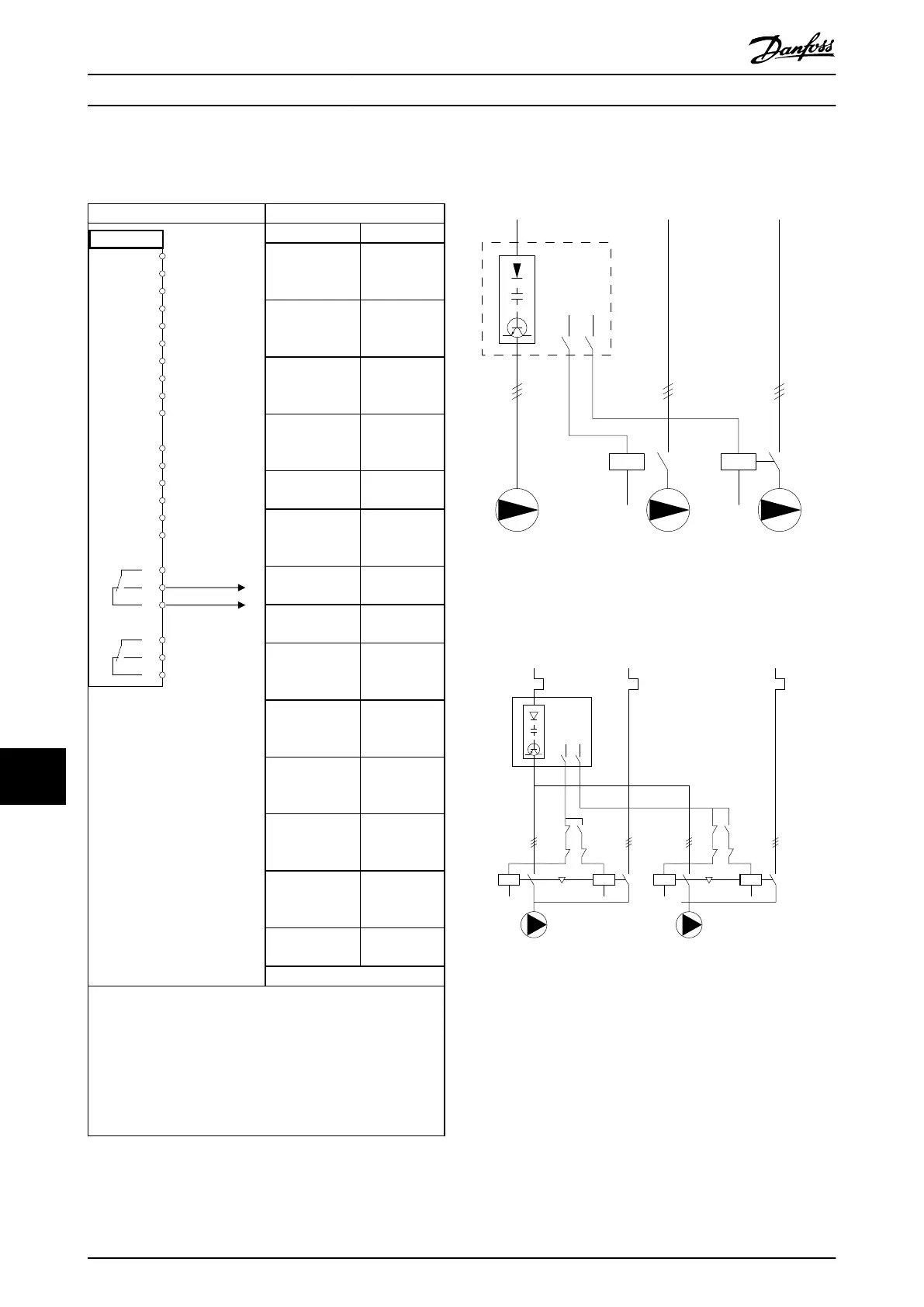

12.10 Wiring Conguration for a Relay Set-

up with Smart Logic Control

Parameters

FC

+24 V

+24 V

D IN

D IN

D IN

COM

D IN

D IN

D IN

D IN

+10 V

A IN

A IN

COM

A OUT

COM

R1R2

12

13

18

19

20

27

29

32

33

37

50

53

54

55

42

39

01

02

03

04

05

06

130BB839.10

Function Setting

Parameter 4-30

Motor Feedback

Loss Function

[1] Warning

Parameter 4-31

Motor Feedback

Speed Error

100 RPM

Parameter 4-32

Motor Feedback

Loss Timeout

5 s

Parameter 7-00 S

peed PID

Feedback Source

[2] MCB 102

Parameter 17-11

Resolution (PPR)

1024*

Parameter 13-00

SL Controller

Mode

[1] On

Parameter 13-01

Start Event

[19] Warning

Parameter 13-02

Stop Event

[44] Reset key

Parameter 13-10

Comparator

Operand

[21] Warning

no.

Parameter 13-11

Comparator

Operator

[1] ≈ (equal)*

Parameter 13-12

Comparator

Value

90

Parameter 13-51

SL Controller

Event

[22]

Comparator 0

Parameter 13-52

SL Controller

Action

[32] Set digital

out A low

Parameter 5-40 F

unction Relay

[80] SL digital

output A

*=Default value

Notes/comments:

If the limit in the feedback monitor is exceeded, warning 90,

Feedback Mon. is issued. The SLC monitors warning 90, Feedback

Mon. and if the warning becomes true, relay 1 is triggered.

External equipment may require service. If the feedback error

goes below the limit again within 5 s, the drive continues and

the warning disappears. Reset relay 1 by pressing [Reset] on the

LCP.

Table 12.13 Wiring Conguration for a Relay Set-up with

Smart Logic Control

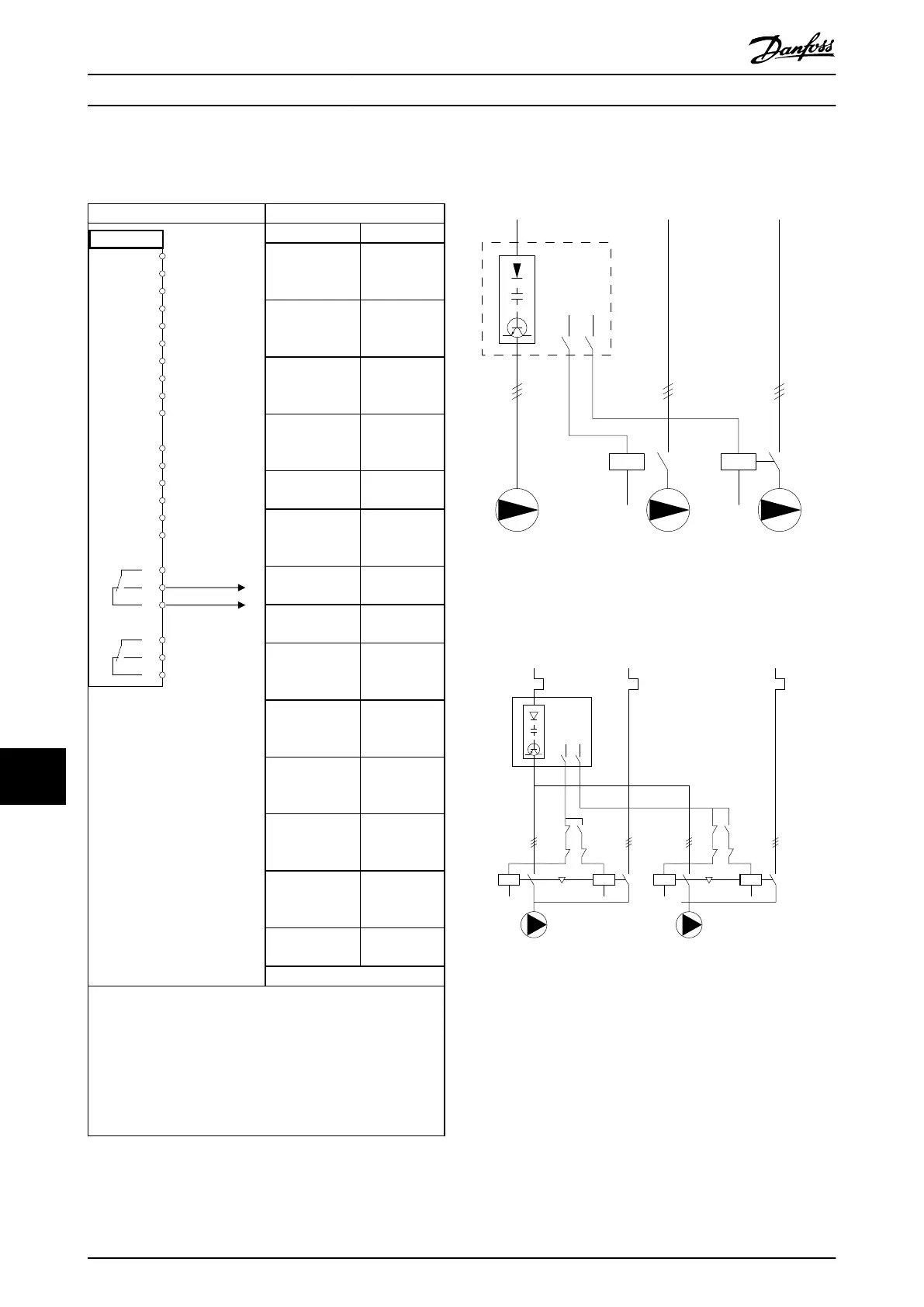

12.11

Wiring Conguration for a Fixed

Variable-speed Pump

L1/L2/L3 L1/L2/L3 L1/L2/L3

Power Section

RELAY 1

RELAY 2

130BA376.10

Illustration 12.5 Fixed Variable Speed Pump Wiring Diagram

12.12 Wiring Conguration for Lead Pump

Alternation

130BA377.13

L1/L2/L3

FC

L1/L2/L3

L1/L2/L3

k3

k2

k3

k1

K2

K1

K1

K1

K4

K3

K4

K3

R1

R2

Illustration 12.6 Lead Pump Alternation Wiring Diagram.

Every pump must be connected to 2 contactors (K1/K2 and

K3/K4) with a mechanical interlock. Thermal relays or other

motor overload protection devices must be applied

according to local regulation and/or individual demands.

•

Relay 1 (R1) and relay 2 (R2) are the built-in relays

in the drive.

•

When all relays are de-energized, the 1

st

built-in

relay that is energized cuts in the contactor

corresponding to the pump controlled by the

Application Examples

VLT

®

HVAC Drive FC 102

214 Danfoss A/S © 11/2017 All rights reserved. MG16C302

1212

Loading...

Loading...