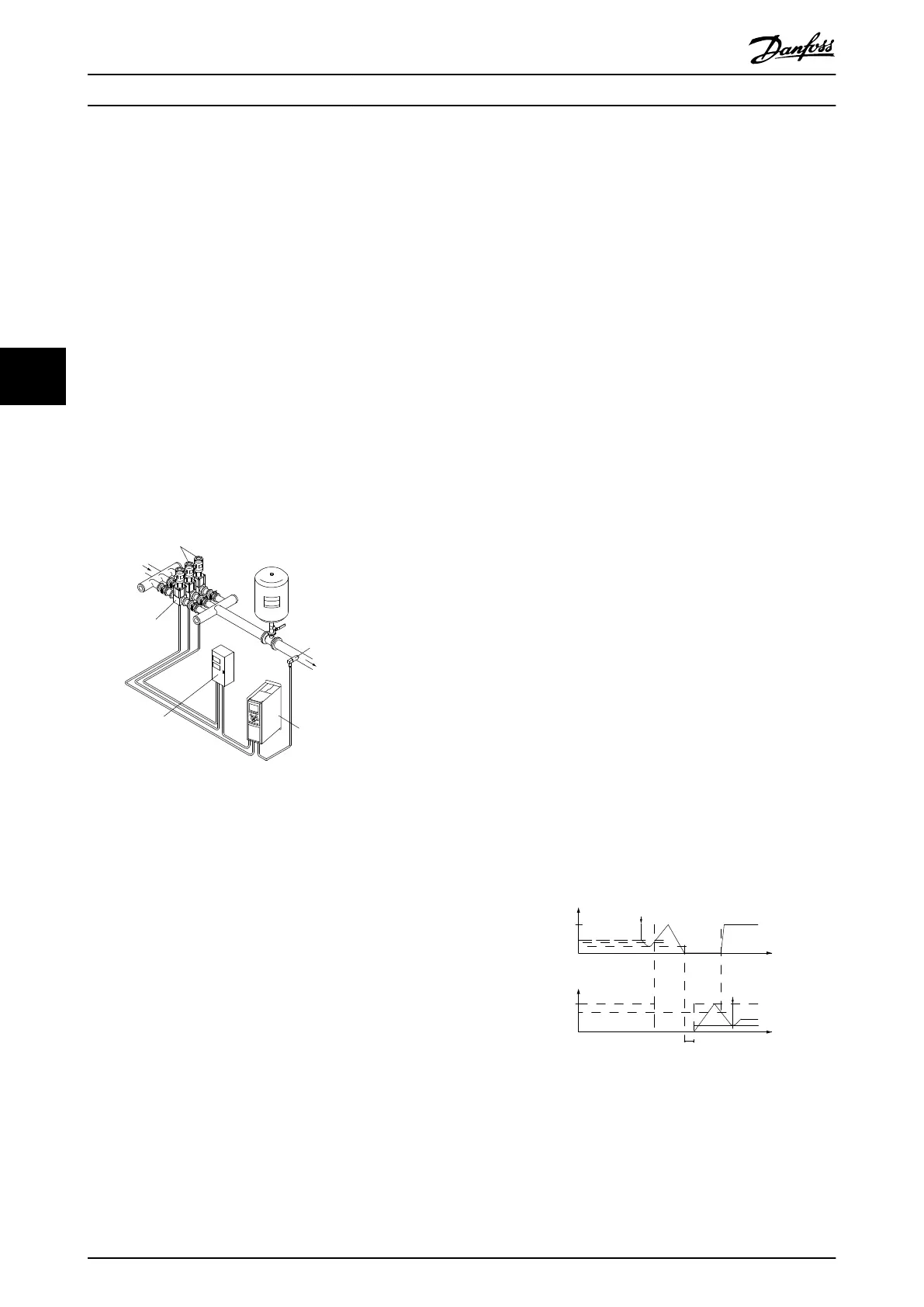

5.4 Basic Cascade Controller

The basic cascade controller is used for pump applications

where a certain pressure (head) or level must be

maintained over a wide dynamic range. Running a large

pump at variable speed over a wide range is not an ideal

solution because of low pump eciency at lower speed. In

a practical way, the limit is 25% of the rated full-load

speed for the pump.

In the basic cascade controller, the drive controls a variable

speed (lead) motor as the variable speed pump and can

stage up to 2 more constant speed pumps on and

o.

Connect the additional constant speed pumps directly to

mains or via soft starters. By varying the speed of the

initial pump, variable speed control of the entire system is

provided. The variable speed maintains constant pressure,

which results in reduced system stress, and quieter

operation in pumping systems.

Constant Speed Pumps (2)

Variable Speed

Pumps (1)

Motor starter

Drive with

Cascade Controller

Pressure Sensor

e30ba362.11

Illustration 5.22 Basic Cascade Controller

Fixed lead pump

The motors must be of equal size. The basic cascade

controller allows the drive to control up to 3 equal pumps

using the 2 built-in relays in the drive. When the variable

pump (lead) is connected directly to the drive, the 2 built-

in relays control the other 2 pumps. When lead pump

alternations are enabled, pumps are connected to the

built-in relays and the drive can operate 2 pumps.

Lead pump alternation

The motors must be of equal size. This function makes it

possible to cycle the drive between the pumps in the

system (maximum of 2 pumps). In this operation, the run-

time between pumps is equalized, reducing the required

pump maintenance and increasing reliability and lifetime

of the system. The alternation of the lead pump can take

place at a command signal or at staging (adding another

pump).

The command can be a manual alternation or an

alternation event signal. If the alternation event is selected,

the lead pump alternation takes place every time the

event occurs. Selections include:

•

Whenever an alternation timer expires.

•

At a predened time of day.

•

When the lead pump goes into sleep mode.

The actual system load determines staging.

A separate parameter limits alternation only to take place if

total capacity required is >50%. Total pump capacity is

determined as lead pump plus xed speed pumps

capacities.

Bandwidth management

In cascade control systems, to avoid frequent switching of

xed-speed pumps, the desired system pressure is kept

within a bandwidth rather than at a constant level. The

staging bandwidth provides the required bandwidth for

operation. When a large and quick change in system

pressure occurs, the override bandwidth overrides the

staging bandwidth to prevent immediate response to a

short duration pressure change. An override bandwidth

timer can be programmed to prevent staging until the

system pressure has stabilized and normal control is

established.

When the cascade controller is enabled and the drive

issues a trip alarm, the system head is maintained by

staging and destaging xed-speed pumps. To prevent

frequent staging and destaging and minimize pressure

uctuations, a wider xed speed bandwidth is used instead

of the staging bandwidth.

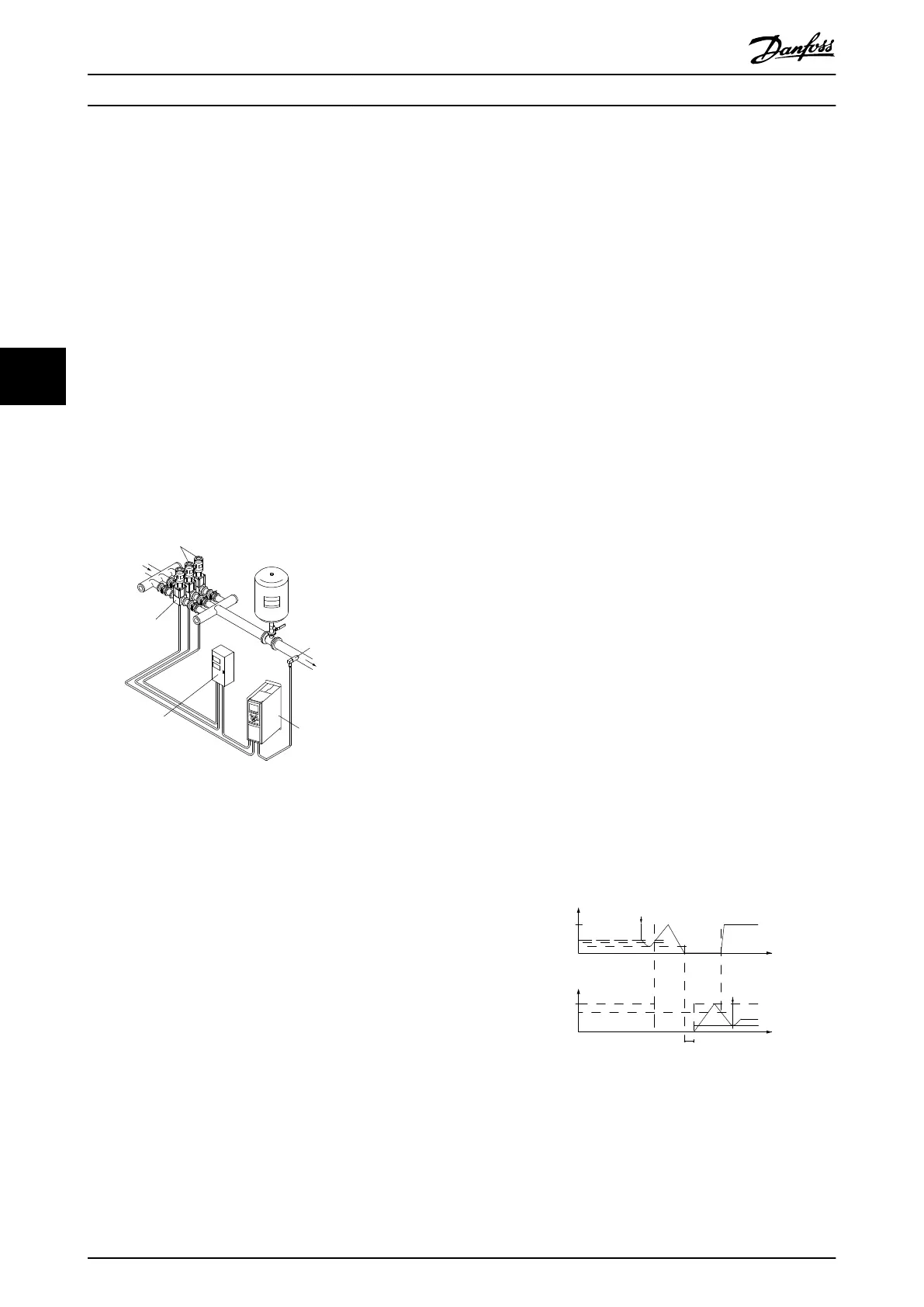

5.4.1.1 Pump Staging with Lead Pump

Alternation

With lead pump alternation enabled, a maximum of 2

pumps are controlled. At an alternation command, the PID

stops, the lead pump ramps to minimum frequency (f

min

)

and, after a delay, it ramps to maximum frequency (f

max

).

When the speed of the lead pump reaches the destaging

frequency, the xed-speed pump is cut out (destaged). The

lead pump continues to ramp up and then ramps down to

a stop and the 2 relays are cut out.

Time

Time

Mains operation

Destaging freq.

Alternation

command/PID stops

Staging freq.

Mains operation

PID contr.

starts

130BA364.10

5s

f

max

f

max

f

min

Illustration 5.23 Lead Pump Alternation

After a time delay, the relay for the

xed-speed pump cuts

in (staged) and this pump becomes the new lead pump.

The new lead pump ramps up to maximum speed and

then down to minimum speed. When ramping down and

reaching the staging frequency, the old lead pump is now

cut in (staged) on the mains as the new xed-speed pump.

Product Features

VLT

®

HVAC Drive FC 102

38 Danfoss A/S © 11/2017 All rights reserved. MG16C302

55

Loading...

Loading...