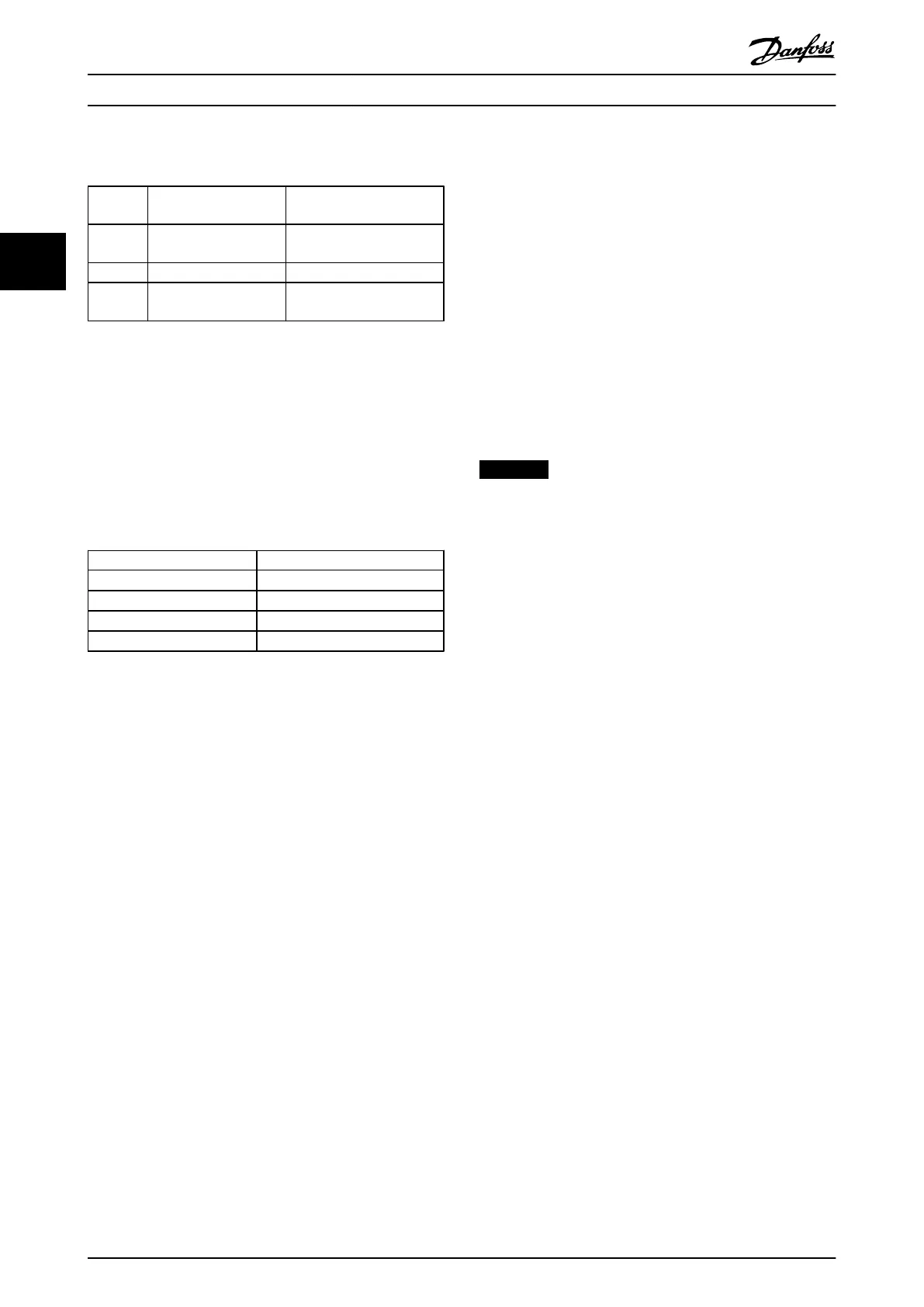

3.6.17 F Enclosure Mains Contactors

Enclosure

Type Power & Voltage Type

F3

P500-P560 380-480 V &

P710-P900 525-690 V Eaton XTCE650N22A

F3 P 630-P710 380-480 V Eaton XTCEC14P22B

F4

P800-P1M0 380-480 V &

P1M0-P1M4 525-690 V Eaton XTCEC14P22B

Table 3.46

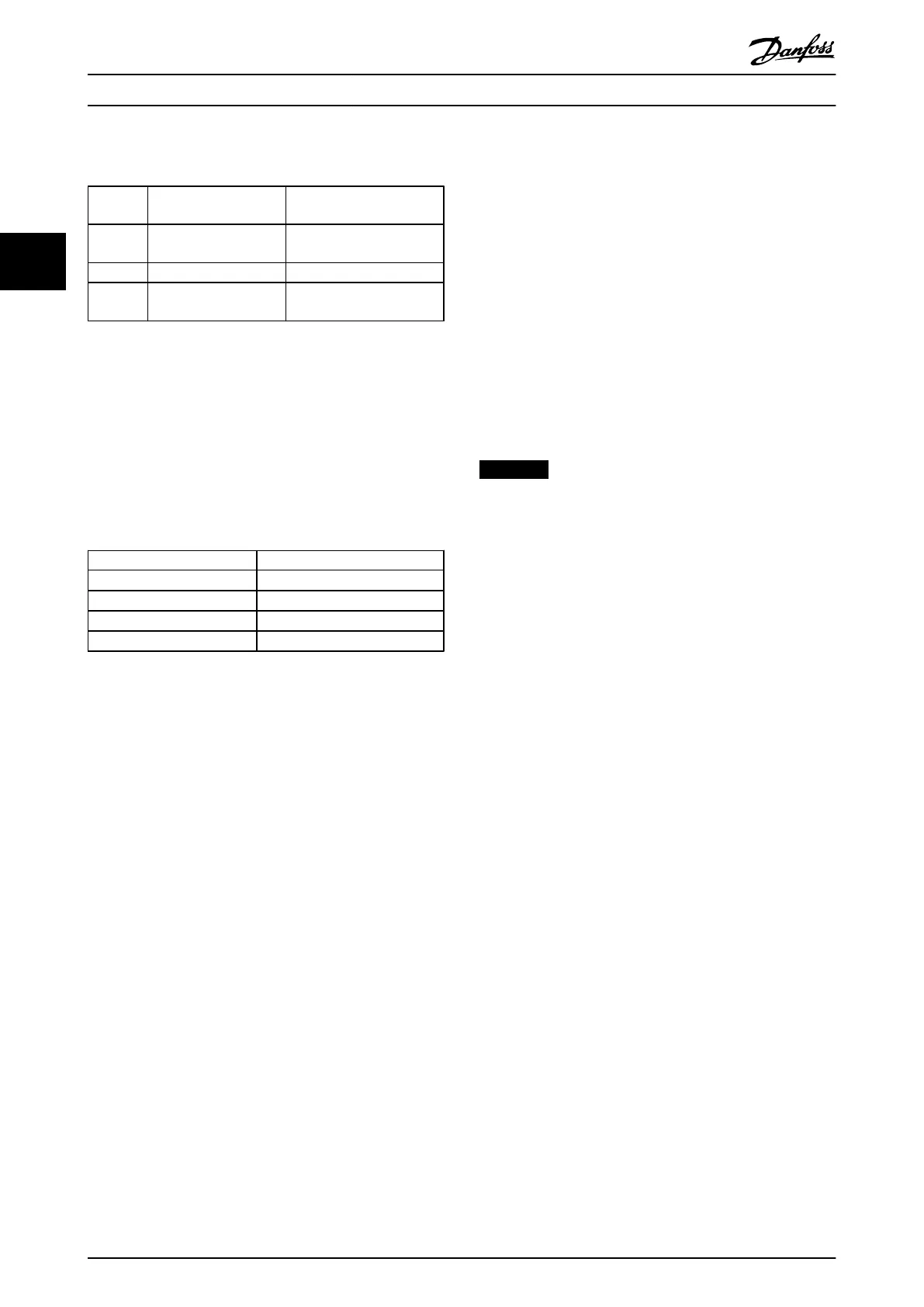

3.6.18 Motor Insulation

For motor cable lengths ≤ the maximum cable length

listed in , the recommended motor insulation ratings are in

Table 3.47. The peak voltage can be up to twice the DC

link voltage, 2.8 times the mains voltage, due to

transmission line effects in the motor cable. If a motor has

a lower insulation rating, use a dU/dt or sine wave filter.

Nominal Mains Voltage Motor Insulation

U

N

≤ 420 V

Standard U

LL

= 1300 V

420 V < U

N

≤ 500 V Reinforced U

LL

= 1600 V

500 V < U

N

≤ 600 V Reinforced U

LL

= 1800 V

600 V < U

N

≤ 690 V Reinforced U

LL

= 2000 V

Table 3.47 Motor Insulation at Various Nominal Mains Voltages

3.6.19

Motor Bearing Currents

For motors with a rating 110 kW or higher operating via

frequency converters use NDE (Non-Drive End) insulated

bearings to eliminate circulating bearing currents due to

the physical size of the motor. To minimise DE (Drive End)

bearing and shaft currents, proper grounding of the

frequency converter, motor, driven machine, and motor to

the driven machine is required. Although failure due to

bearing currents is rare, if it occurs, use the following

mitigation strategies.

Standard mitigation strategies

•

Use an insulated bearing

•

Apply rigorous installation procedures

-

Ensure the motor and load motor are

aligned

-

Strictly follow the EMC Installation

guideline

-

Reinforce the PE so the high frequency

impedance is lower in the PE than the

input power leads

-

Provide a good high frequency

connection between the motor and the

frequency converter by screened cable,

which has a 360° connection in the

motor and frequency converter

-

Ensure that the impedance from

frequency converter to building ground

is lower than the grounding impedance

of the machine. Make a direct earth

connection between the motor and load

motor

•

Apply conductive lubrication

•

Try to ensure that the line voltage is balanced to

ground. This can be difficult for IT, TT, TN-CS or

Grounded leg systems

•

Use an insulated bearing as recommended by the

motor manufacturer

NOTICE

Motors from reputable manufacturers typically have

these fitted as standard in motors of this size.

If none of these strategies works, consult the factory.

If necessary after consulting Danfoss:

•

Lower the IGBT switching frequency

•

Modify the inverter waveform, 60° AVM vs.

SFAVM

•

Install a shaft grounding system or use an

isolating coupling between motor and load

•

Use minimum speed settings if possible

•

Use a dU/dt or sinus filter

3.6.20

Control Cable Routing

Tie down all control wires to the designated control cable

routing as shown in the picture. Remember to connect the

shields in a proper way to ensure optimum electrical

immunity.

Fieldbus connection

Connections are made to the relevant options on the

control card. For details, see the relevant fieldbus

instruction. The cable must be placed in the provided path

inside the frequency converter and tied down with other

control wires (see illustrations).

How to Install

VLT AQUA Drive FC 202 Operation Instructions

60 MG20P402 - Rev. 2013-12-16

33

Loading...

Loading...