Press [

▲

] and [

▼

] to change the data value. [

▲

] increases

the data value, and [

▼

] decreases the data value. Place the

cursor on the value to be saved and press [OK].

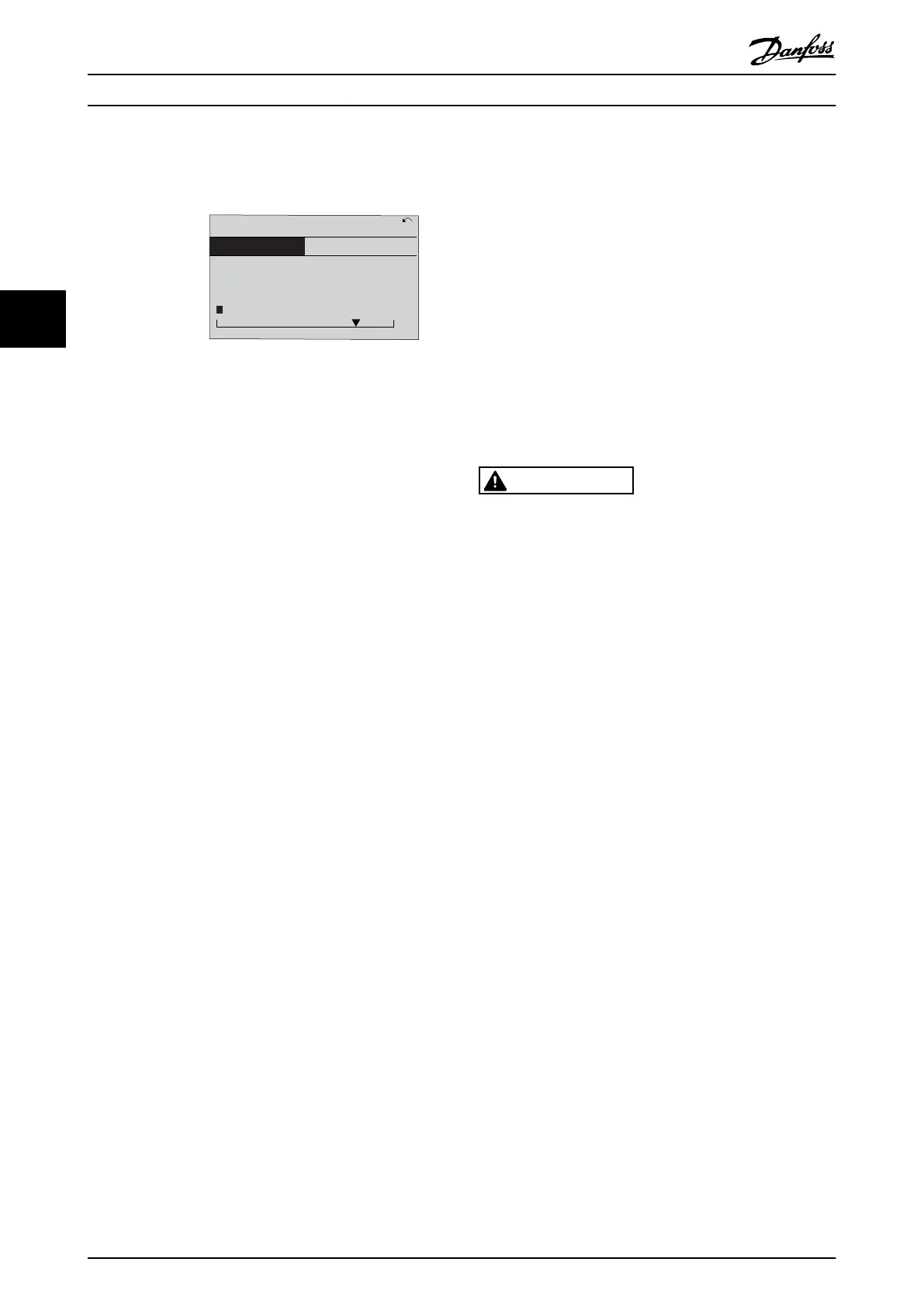

130BP070.10

1 - 60 Low speed load

compensation

1 0%

Load depen. setting 1- 6*

729RPM 6.21A 1(1)

6

Illustration 4.20 Display Example

4.1.6 Changing of Data Value, Step-by-Step

Certain parameters can be changed step by step or

infinitely variably. This applies to parameter 1-20 Motor

Power [kW], parameter 1-22 Motor Voltage and

parameter 1-23 Motor Frequency.

The parameters are changed both as a group of numeric

data values and as numeric data values infinitely variably.

4.1.7

Read-out and Programming of

Indexed Parameters

Parameters are indexed when placed in a rolling stack.

15-30 Alarm Log: Error Code to 15-32 Alarm Log: Time

contain a fault log which can be read out. Select a

parameter, press [OK], and use [

▲

] and [

▼

] to scroll

through the value log.

Use parameter 3-10 Preset Reference as another example:

Select the parameter, press [OK], and use [

▲

] and [

▼

] to

scroll through the indexed values. To change the

parameter value, select the indexed value and press [OK].

Change the value by [

▲

] and [

▼

]. Press [OK] to accept the

new setting. Press [Cancel] to abort. Press [Back] to leave

the parameter.

4.1.8

Tips and Tricks

•

For the majority of water and wastewater

applications the Quick Menu, Quick Set-up and

Function Set-up provides the simplest and

quickest access to all the typical parameters

required.

•

Whenever possible, performing an AMA, ensures

best shaft performance.

•

Contrast of the display can be adjusted by

pressing [Status] and [▲] for darker display or by

pressing [Status] and [▼] for brighter display.

•

Under [Quick Menu] and [Changes Made] all

parameters that have been changed from factory

settings are displayed.

•

Press and hold [Main Menu] key for 3 s for access

to any parameter.

•

For service purposes it is recommended to copy

all parameters to the LCP, see 0-50 LCP Copy for

further information.

4.1.9 Quick Transfer of Parameter Settings

when Using GLCP

Once the set-up of a frequency converter is complete, it is

recommended to store (back up) the parameter settings in

the GLCP or on a PC via MCT 10 Set-up Software Tool.

WARNING

Stop the motor before performing any of these

operations.

Data storage in LCP

1.

Go to 0-50 LCP Copy.

2. Press [OK].

3.

Select [1] All to LCP.

4. Press [OK].

All parameter settings are now stored in the GLCP

indicated by the progress bar. When 100% is reached,

press [OK].

The GLCP can now be connected to another frequency

converter and the parameter settings copied to this

frequency converter.

Data transfer from LCP to Frequency converter

1.

Go to 0-50 LCP Copy.

2. Press [OK].

3.

Select [2] All from LCP.

4. Press [OK]

The parameter settings stored in the GLCP are now

transferred to the frequency converter indicated by the

progress bar. When 100% is reached, press [OK].

4.1.10

Initialisation to Default Settings

There are 2 ways to initialise the frequency converter to

default: Recommended initialisation and manual initiali-

sation.

Be aware that they have different impact according to the

below description.

How to operate the frequenc...

VLT AQUA Drive FC 202 Operation Instructions

76 MG20P402 - Rev. 2013-12-16

44

Loading...

Loading...