5.2.7 Cooling and Airflow

Cooling

Cooling can be obtained in different ways, by using the cooling ducts in the bottom and the top of the unit, by taking air in and out the back of the unit

or by combining the cooling possibilities.

Duct cooling

A dedicated option has been developed to optimize installation of IP00/chassis frame adjustable frequency drives in Rittal TS8 enclosures utilizing the

fan of the adjustable frequency drive for forced air cooling of the backchannel. The air out the top of the enclosure could but ducted outside a facility so

the heat losses from the backchannel are not dissipated within the control room reducing air-conditioning requirements of the facility.

Please see

Installation of Duct Cooling Kit in Rittal enclosures

, for further information.

Back cooling

The backchannel air can also be ventilated in and out the back of a Rittal TS8 enclosure. This offers a solution where the backchannel could take air from

outside the facility and return the heat losses outside the facility thus reducing air-conditioning requirements.

NOTE!

A door fan or fans are required on the Rittal cabinet to remove the losses not contained in the backchannel of the drive. The minimum

door fan airflow required at the drive maximum ambient for the D3 and D4 is 391 m^3/h (230 cfm). The minimum door fan airflow

required at the drive maximum ambient for the E2 is 782 m^3/h (460 cfm). If the ambient is below maximum or if additional components

and heat loss are added within the enclosure, a calculation must be made to ensure the proper airflow is provided to cool the inside

of the Rittal enclosure.

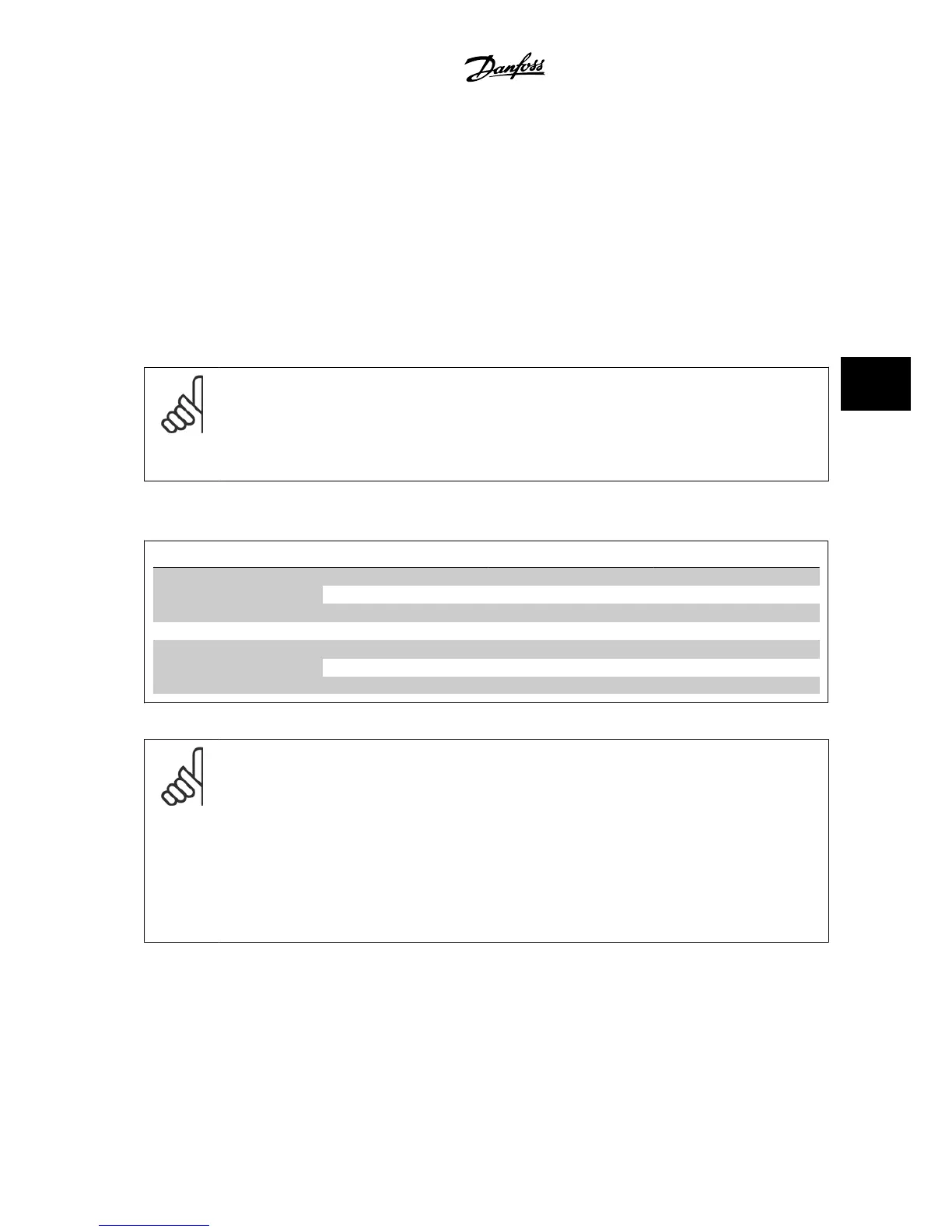

Airflow

The necessary airflow over the heatsink must be ensured. The flow rate is shown below.

Enclosure protection Frame size Door fan/Top fan airflow Airflow over heatsink

IP21 / NEMA 1

IP54 / NEMA 12

D1 and D2

6,003 ft

3

/h [170 m

3

/h] (100 cfm) 27,015 ft

3

[765 m

3

/h] (450 cfm)

E1

12,006 ft

3

/h [340 m

3

/h] (200 cfm) 50,994 ft

3

/h [1,444 m

3

/h] (850 cfm)

IP21 / NEMA 1 F1, F2, F3 and F4

24,720 ft

3

/h [700 m

3

/h] (412 cfm)* 34,784 ft

3

/h [985 m

3

/h] (580 cfm)

IP54 / NEMA 12 F1, F2, F3 and F4

18,540 ft

3

/h [525 m

3

/h] (309 cfm)* 34,784 ft

3

/h [985 m

3

/h] (580 cfm)

IP00 / Chassis D3 and D4

9,005 ft

3

/h [255 m

3

/h] (150 cfm) 27,015 ft

3

[765 m

3

/h] (450 cfm)

E2

9,005 ft

3

/h [255 m

3

/h] (150 cfm) 50,994 ft

3

/h [1,444 m

3

/h] (850 cfm)

* Airflow per fan. Frame size F contain multiple fans.

Table 5.2: Heatsink Air Flow

NOTE!

The fan runs for the following reasons:

1. AMAAuto-tune

2. DC Hold

3. Pre-Mag

4. DC Brake

5. 60% of nominal current is exceeded

6. Specific heatsink temperature exceeded (power-size dependent).

Once the fan is started, it will run for a minimum of 10 minutes.

5.2.8 Gland/Conduit Entry - IP21 (NEMA 1) and IP54 (NEMA12)

Cables are connected through the gland plate from the bottom. Remove the plate, and plan where to place the entry for the glands or conduits. Prepare

holes in the marked area on the drawing.

VLT

®

AQUA Drive Design Guide 5 How to Install

MG.20.N5.22 - VLT

®

is a registered Danfoss trademark

5-11

5

Loading...

Loading...