2.13 Control with brake function

2.13.1 Selection of Brake Resistor

In certain applications, for instance, in centrifuges, it is desirable to bring the motor to a stop more rapidly than can be achieved through controlling via

ramp-down or by free-wheeling. In such applications, dynamic braking with a braking resistor may be utilized. Using a braking resistor ensures that the

energy is absorbed in the resistor and not in the adjustable frequency drive.

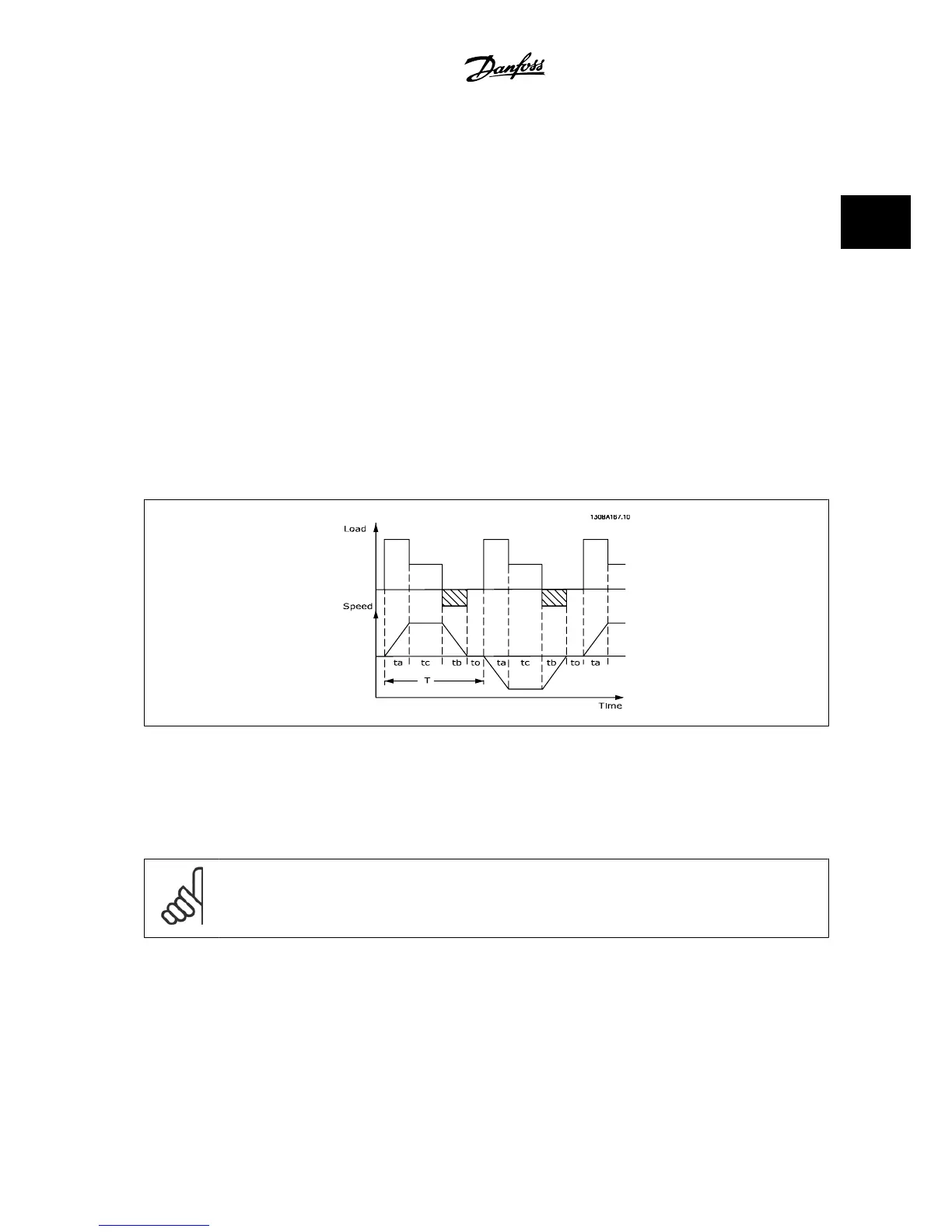

If the amount of kinetic energy transferred to the resistor in each braking period is not known, the average power can be calculated on the basis of the

cycle time and braking time, also known as the intermitted duty cycle. The resistor intermittent duty cycle is an indication of the duty cycle at which the

resistor is active. The below figure shows a typical braking cycle.

The intermittent duty cycle for the resistor is calculated as follows:

Duty Cycle = t

b

/T

T = cycle time in seconds

t

b

is the braking time in seconds (as part of the total cycle time)

Danfoss offers brake resistors with a duty cycle of 5%, 10% and 40%, which are all suitable for use with the FC202 AQUA drive series. If a 10% duty

cycle resistor is applied, it is capable of absorbing braking energy up to 10% of the cycle time, with the remaining 90% being used to dissipate heat from

the resistor.

For further selection advice, please contact Danfoss.

NOTE!

If a short circuit in the brake transistor occurs, power dissipation in the brake resistor is only prevented by using a line switch or

contactor to disconnect the line power for the adjustable frequency drive. (The contactor can be controlled by the adjustable frequency

drive).

VLT

®

AQUA Drive Design Guide 2 Introduction to the VLT AQUA Drive

MG.20.N5.22 - VLT

®

is a registered Danfoss trademark

2-27

2

Loading...

Loading...