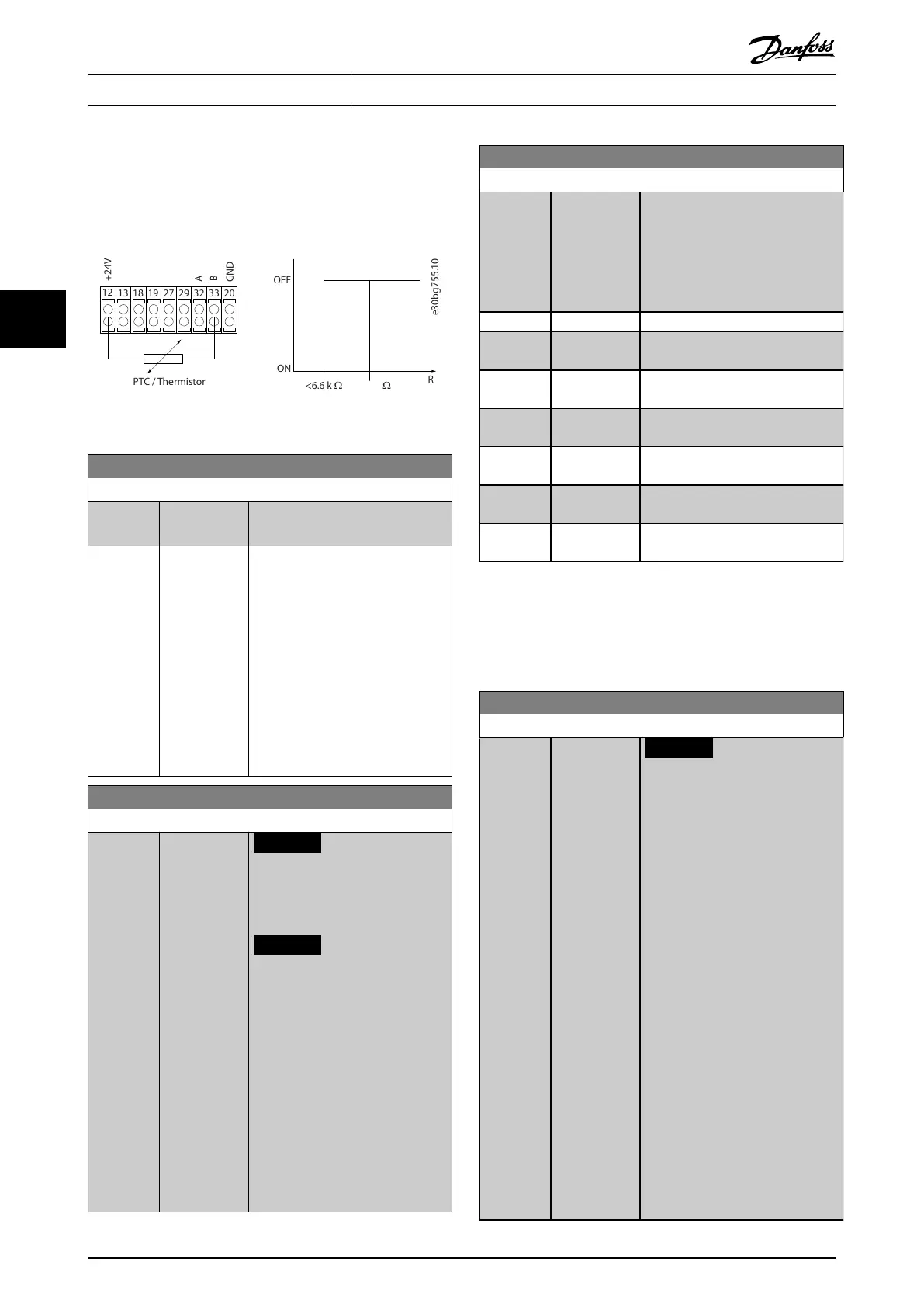

Parameter set-up:

•

Set parameter 1-90 Motor Thermal Protection to [2]

Thermistor Trip.

•

Set parameter 1-93 Thermistor Source to [6] Digital

Input.

Illustration 4.13 Thermistor Connection

1-91 Motor External Fan

Option: Function:

[0] * No No external fan is required, that is

the motor is derated at low speed.

[1] Yes Applies an external motor fan

(external ventilation), so no

derating of the motor is required at

low speed. The upper curve in

Illustration 4.12 (f

out

= 1 x f

M,N

) is

followed if the motor current is

lower than nominal motor current

(see parameter 1-24 Motor Current).

If the motor current exceeds

nominal current, the operation time

still decreases as if no fan was

installed.

1-93 Thermistor Source

Option: Function:

NOTICE

This parameter cannot be

adjusted while the motor is

running.

NOTICE

Set digital input to [0] PNP -

Active at 24 V in

parameter 5-00 Digital I/O

Mode.

Select the input to which the

thermistor (PTC sensor) should be

connected. An analog input option

[1] Analog Input 53 or [2] Analog

Input 54 cannot be selected if the

analog input is already in use as a

reference source (selected in

parameter 3-15 Reference 1 Source,

1-93 Thermistor Source

Option: Function:

parameter 3-16 Reference 2 Source,

or parameter 3-17 Reference 3

Source).

When using VLT

®

PTC Thermistor

Card MCB 112, always select [0]

None.

[0] * None

[1] Analog Input

53

[2] Analog Input

54

[3] Digital input

18

[4] Digital input

19

[5] Digital input

32

[6] Digital input

33

4.3 Parameters: 2-** Brakes

4.3.1 2-0* DC brakes

Parameter group for conguring the DC brake and DC hold

functions.

2-00 DC Hold Current

Range: Function:

50 %* [ 0 - 160 %]

NOTICE

The maximum value depends

on the rated motor current.

Avoid 100% current for too

long. It may damage the

motor.

Low values of DC hold

produce larger than expected

currents with larger motor

power sizes. This error

increases as the motor power

increases.

Enter a value for holding current as

a percentage of the rated motor

current I

M,N

set in

parameter 1-24 Motor Current. 100%

DC hold current corresponds to I

M,N

.

This parameter holds the motor

function (holding torque) or

preheats the motor.

This parameter is active if DC hold

is selected in parameter 1-72 Start

Function [0] or

parameter 1-80 Function at Stop [1].

Parameter Descriptions VLT® AutomationDrive FC 361

48 Danfoss A/S © 03/2019 All rights reserved. MG06J202

44

Loading...

Loading...