Requirements placed on the steam steriliser:

– Corresponds to EN 13060 or EN 285 and/or

ANSI AAMI ST79

– Suitable programme for the products listed

(e. g. with hollow bodies, fractionated vacuum

procedure in three vacuum steps)

– Sufficient product drying

– Validated process in accordance with DIN EN

ISO 17665 (valid IQ/OQ and product-specific

performance appraisal (PQ)

Perform the following steps:

❯

Sterilise the parts for sterilisation (at least 20

minutes at 121°C, at least 4 minutes at 132°C

or at least 5 minutes at 134°C).

Do not exceed 138 °C.

Marking

❯

Mark the packaged, treated medical product in

such a way as to ensure safe application.

10.8 Issue clearance for the parts

for sterilisation

The reprocessing of the medical products ends

with the documented clearance for storage and

renewed use.

❯

Document the clearance of the medical prod-

uct after reprocessing.

10.9 Storing parts for sterilisation

❯

Comply with the stated storage conditions:

– Store the parts protected against contami-

nation

– Dust-protected, e.g. in a locked cabinet

– Protected against moisture

– Protected against excessive temperature

fluctuations

– Protected against damage

Packaging for a sterile medical device can suf-

fer damage as a result of a particular incident

and the passage of time.

Potential external contamination of the sterile

barrier system should be taken into account in

terms of aseptic preparation when establishing

the storage conditions.

11 Cleaning

11.1 Cleaning the optical element

NOTICE

Damage of the optical element from

incorrect cleaning

❯

Only use the cleaning set for VistaCam

optical element. Disinfectant residues

soil the optical element.

❯

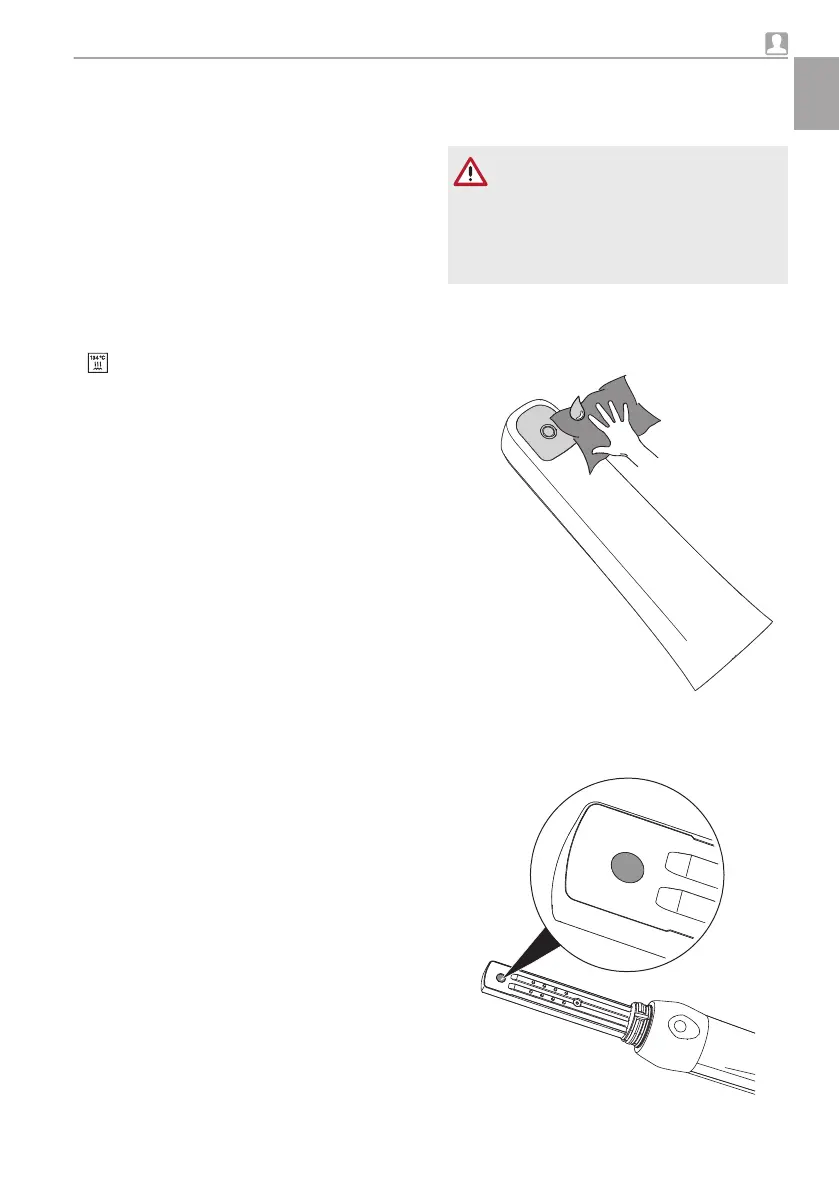

Clean the window of the optical window of the

interchangeable head from outside using the

microfibre cloth with a drop of VistaCam optical

element cleaner or alcohol.

❯

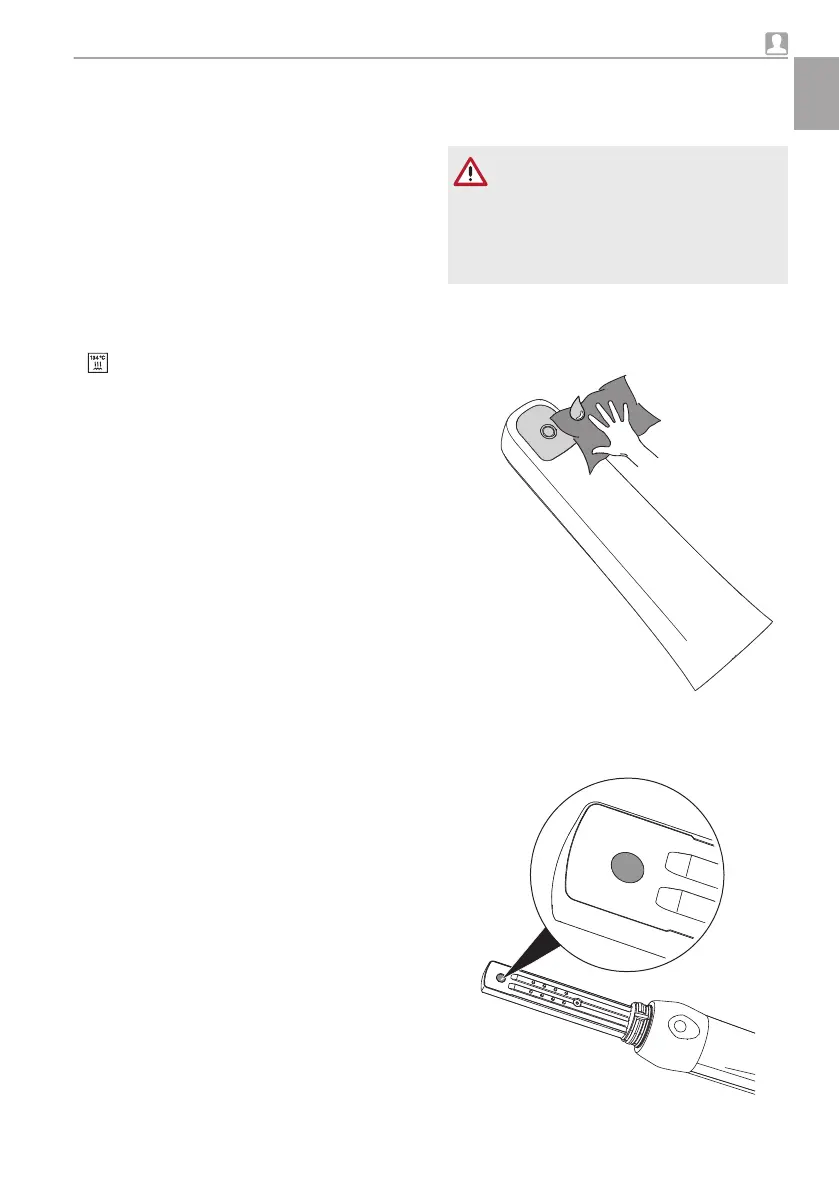

With the interchangeable head removed, clean

the surface of the image sensor using the

cleaning set for VistaCam Optik.

Usage

9000-618-176/30 1812V009 31

EN

Loading...

Loading...