Troubleshooting 2–7

Amperage Checks

Using a clamp-on amp meter can be helpful for identifying problems such as a restricted or

blocked discharge line, blown stator, or faulty check valve/anti-siphon.

1. Set the clamp-on amp meter to the appropriate scale.

2. Hook the probe around the black power lead in the alarm panel.

3. With the power on, ll the tank until the pump operates, or press the push-to-run

switch in the alarm panel.

4. Read the current directly. Refer to the following table for troubleshooting.

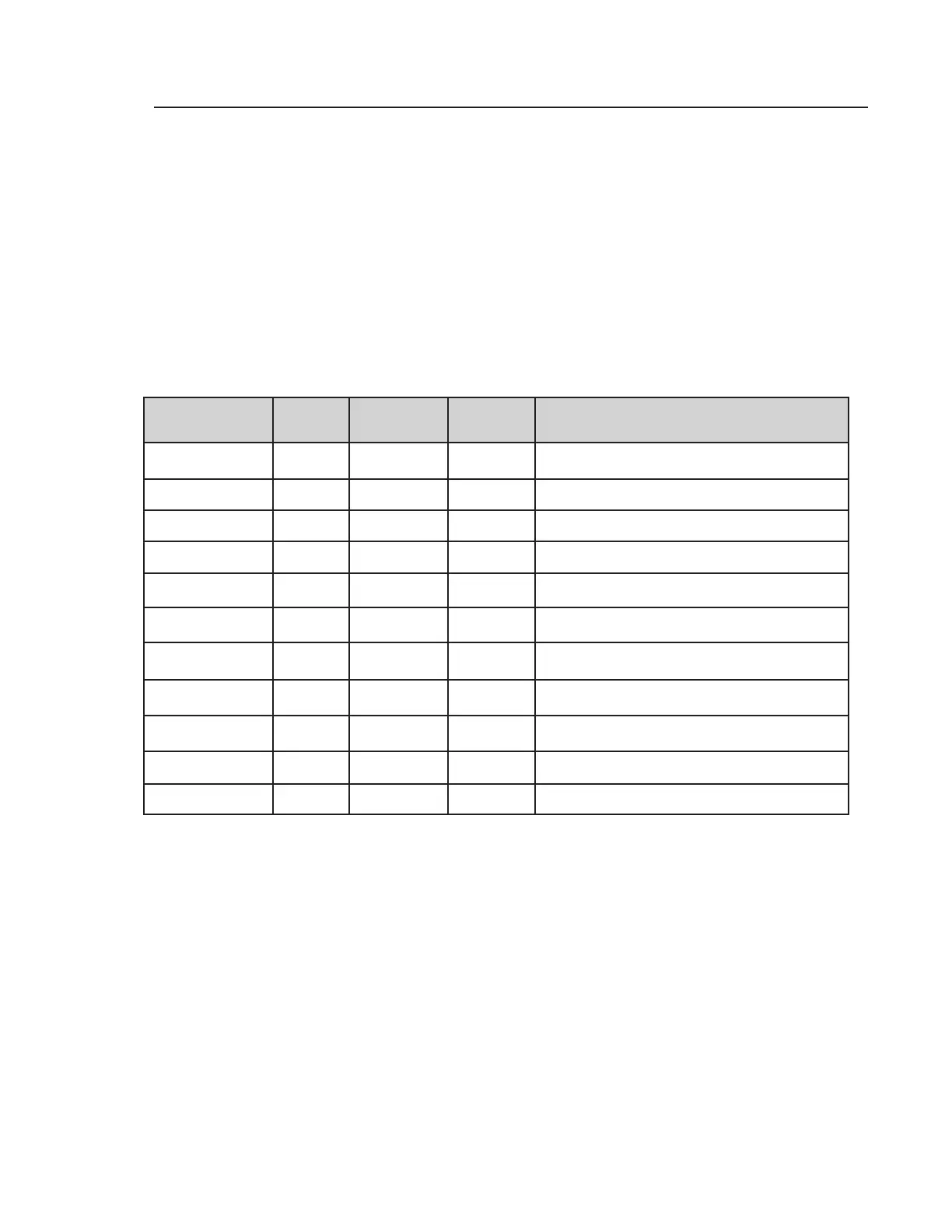

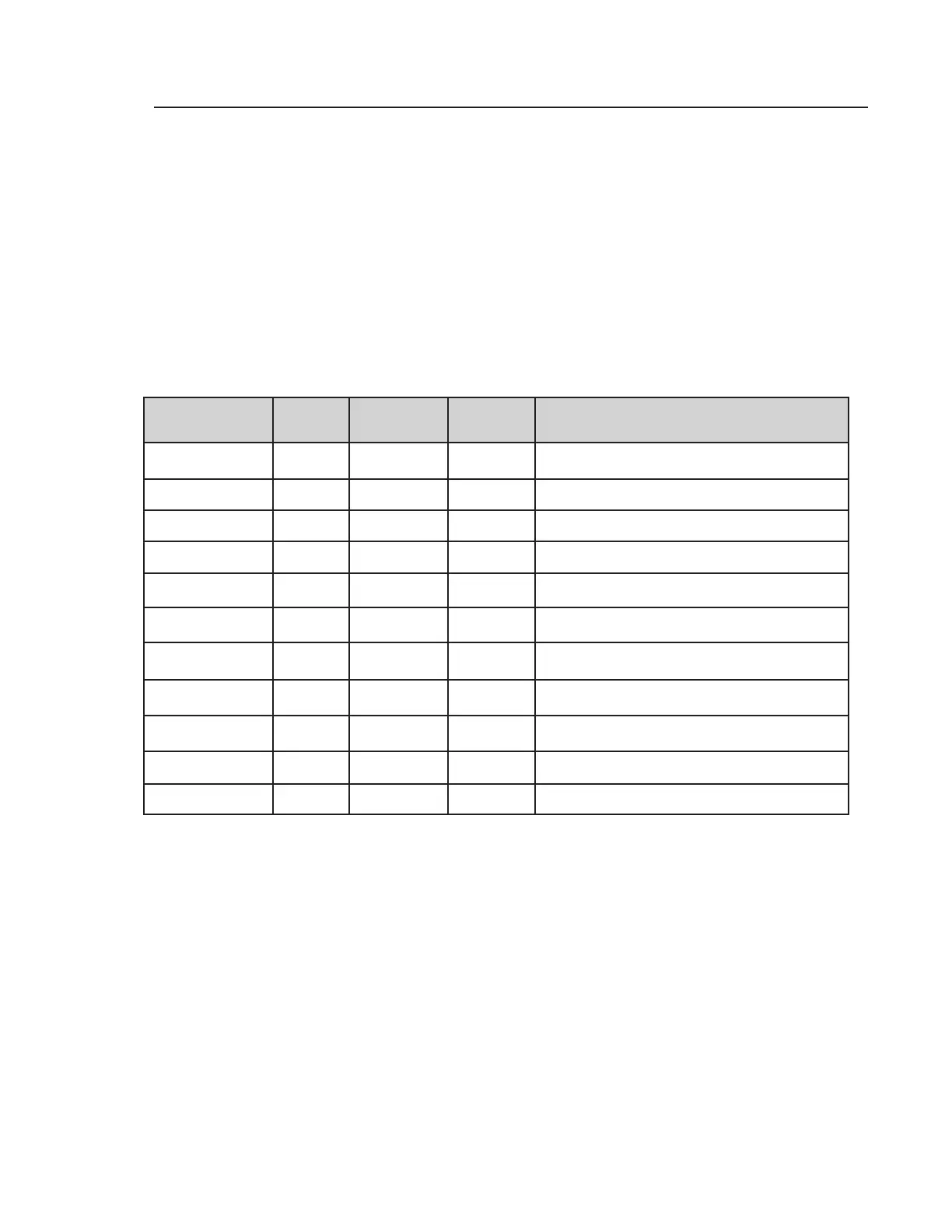

The gures shown are averages and should be used for approximation because motors,

voltages and amp meters vary. The table displays a comparison of back pressure (psi), ow

(gpm), current draw (amperes) and head (feet of water pressure).

A jammed grinder may trip the circuit breaker or cause the overload protector to cycle. This

causes the pump to cycle on and off and eventually results in an alarm condition. A torn or

worn out pump stator results in a “runs but does not pump” condition and eventually, as the

water rises, causes an alarm. Replace the stator and, if necessary, the rotor.

Amps @

240V (120V)

PSI Head (ft) GPM Comments

4.9 (9.8) or less 0 0 0 Worn stator

5.6 (11.2) 10 24 14 Normal

5.8 (11.6) 20 46 13 Normal

6 (12) 30 70 12 Normal

6.2 (12.4) 40 92 11 Normal

6.5 (13) 50 115 10 Normal

6.8 (13.6) 60 138 9 Normal

7.1 (14.2) 70 161 8 Normal

7.4 (14.8) 80 184 7.5 Normal

8+ (16+) 90+ 207+ Varies Plugged discharge line or bad bearings

>15 (>30) 0 0 0 Jammed grinder or shorted motor

Table 2–7

Loading...

Loading...