Pump End 5–5

Inspecting a Pump Rotor

The pump rotor has a life expectancy of about 15 years. Besides age, the following can cause

rotor wear:

• High ow (business, industry or inltration)

• Abrasives

• Pump running dry

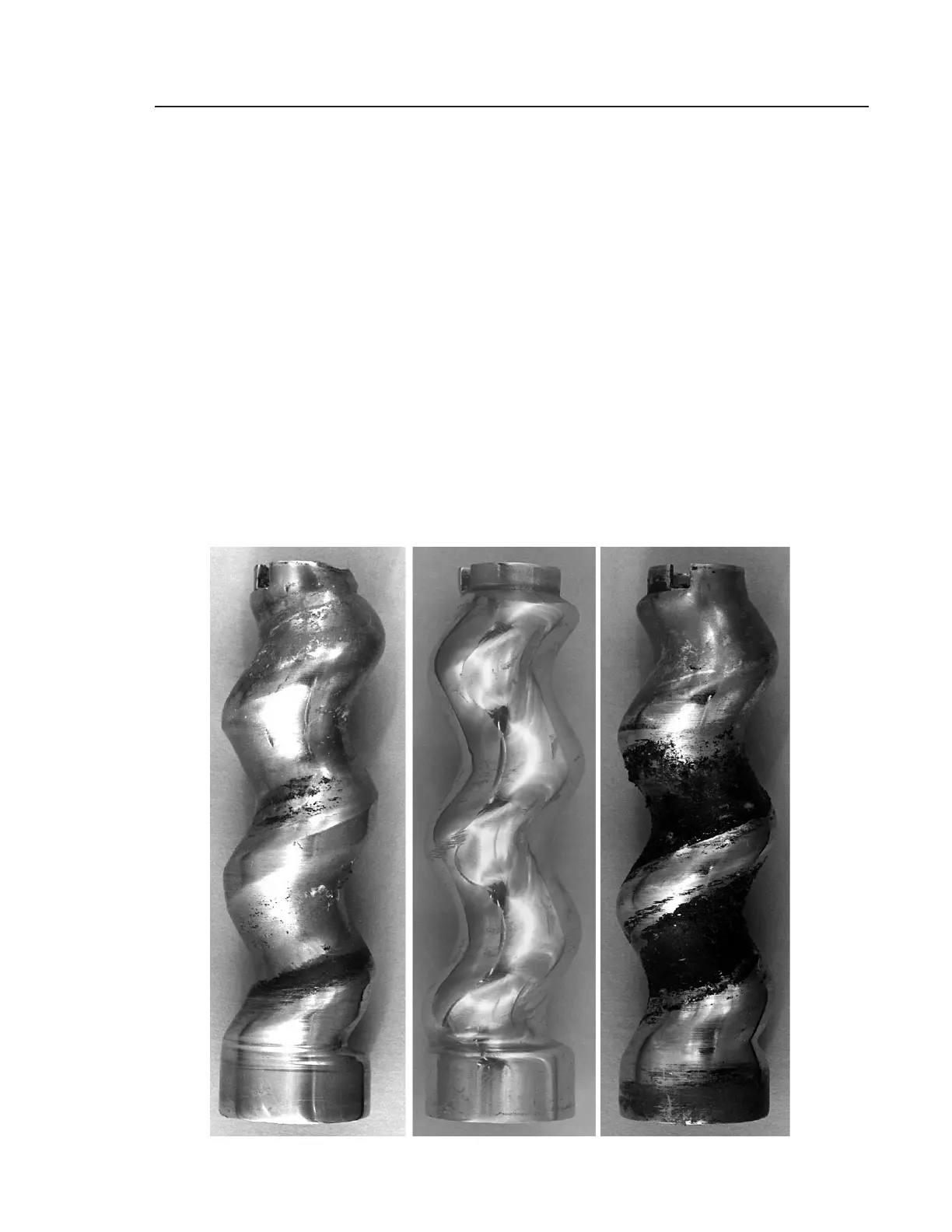

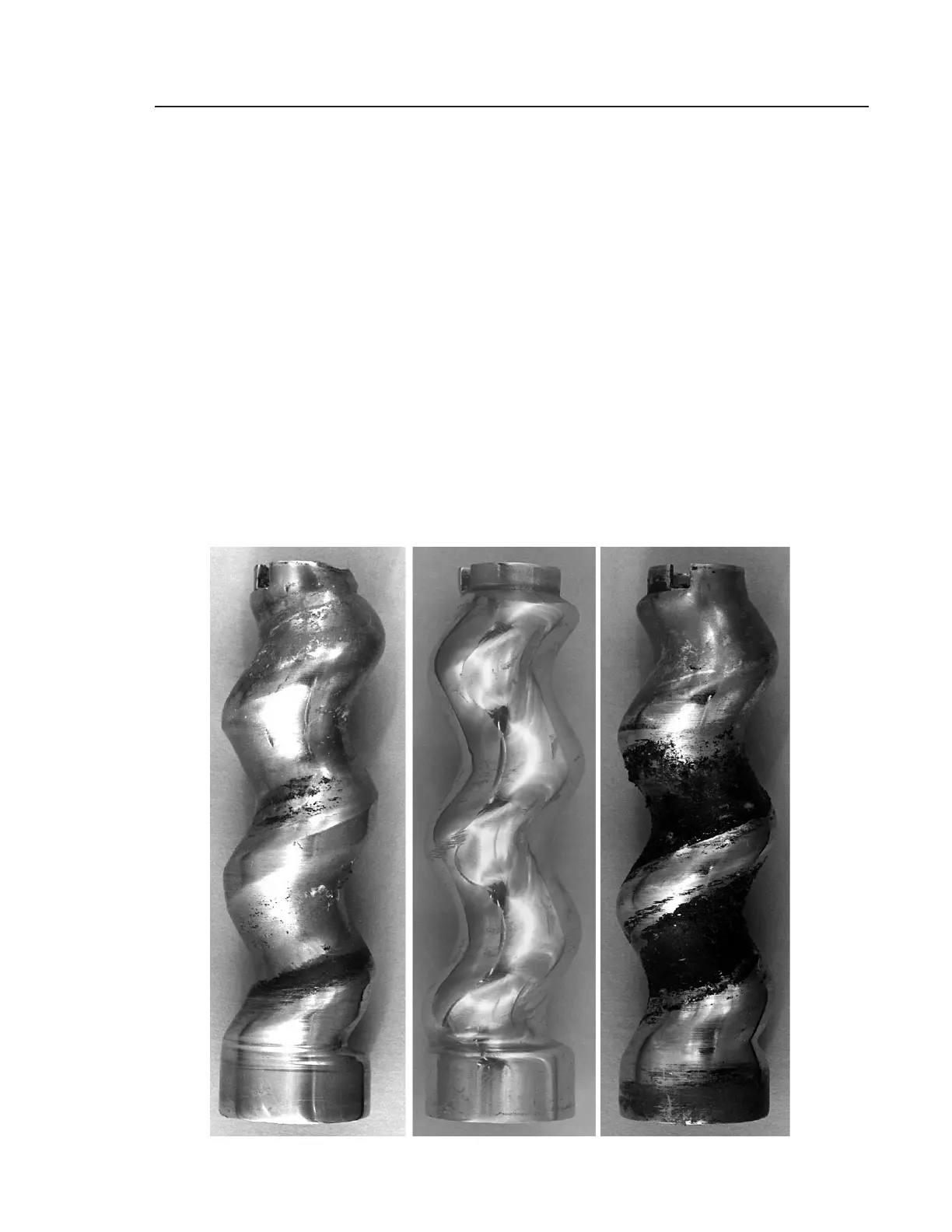

The rotor does not have to be removed from the motor shaft for inspection. When inspecting

the rotor, do not worry about scratches, lines, casting marks or pit marks. Check the high,

rounded lobes that spiral the length of the rotor. If the lobes have been worn at into a 1/4-inch

or wider band, the rotor is worn and must be replaced.

Rubber found on the rotor indicates that the pump has run dry. Rubber can be cleaned with

acetone, paint thinner or other petroleum cleaner. Inspect the rotor for excessive wear and

replace it if necessary. If unsure, replace the stator and liner and perform a ow check. Flow

should read about 14 gpm at 15 psi. Run the pump allowing the discharge to ow into a 5

gallon bucket. Filling the bucket at 15 psi should take about 23 seconds.

Worn New Rubber

(Run Dry)

Loading...

Loading...