Safety and operating instructions

40 © Construction Tools GmbH | 3390 5203 01 | 2019-08-06

Original Instructions

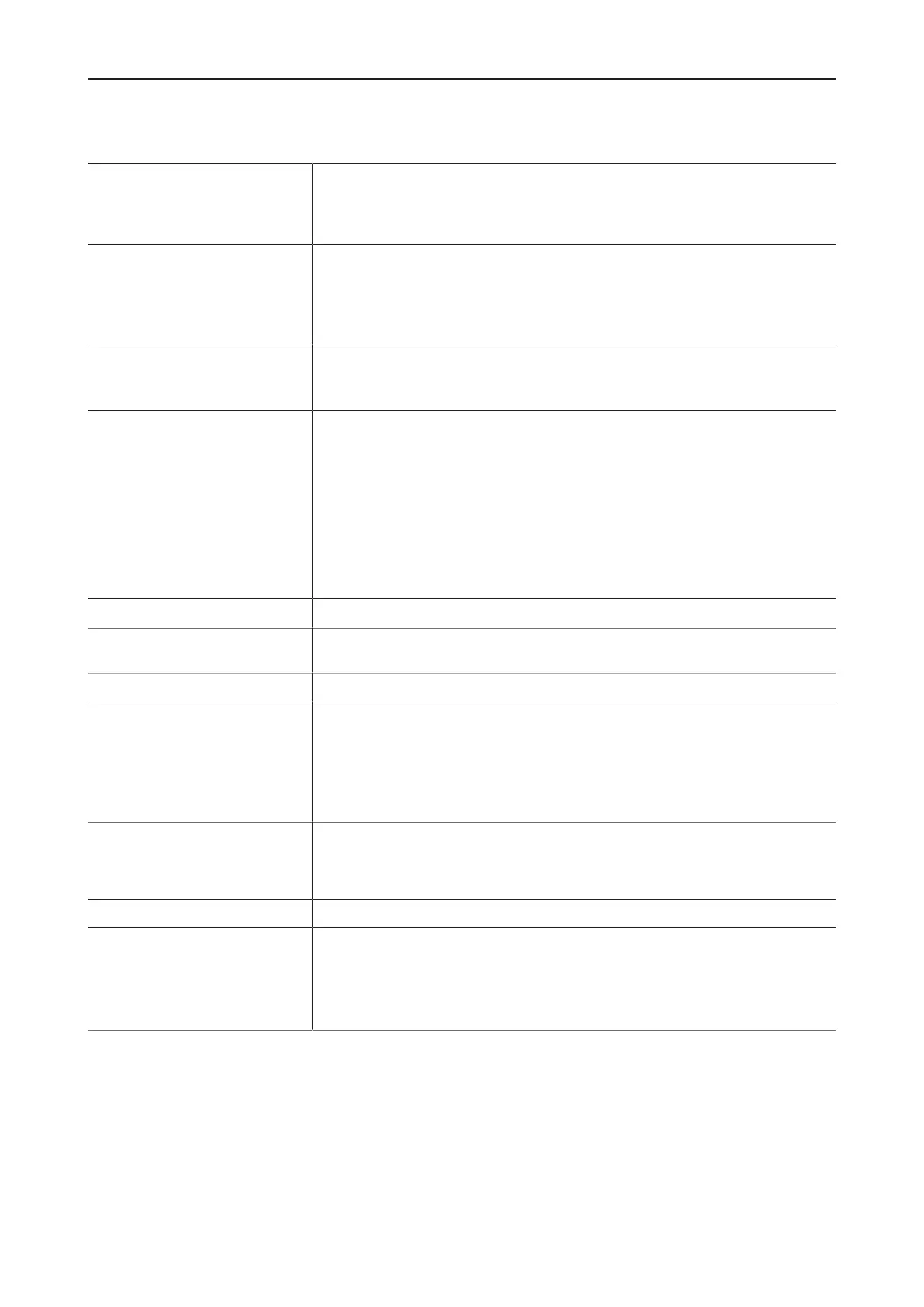

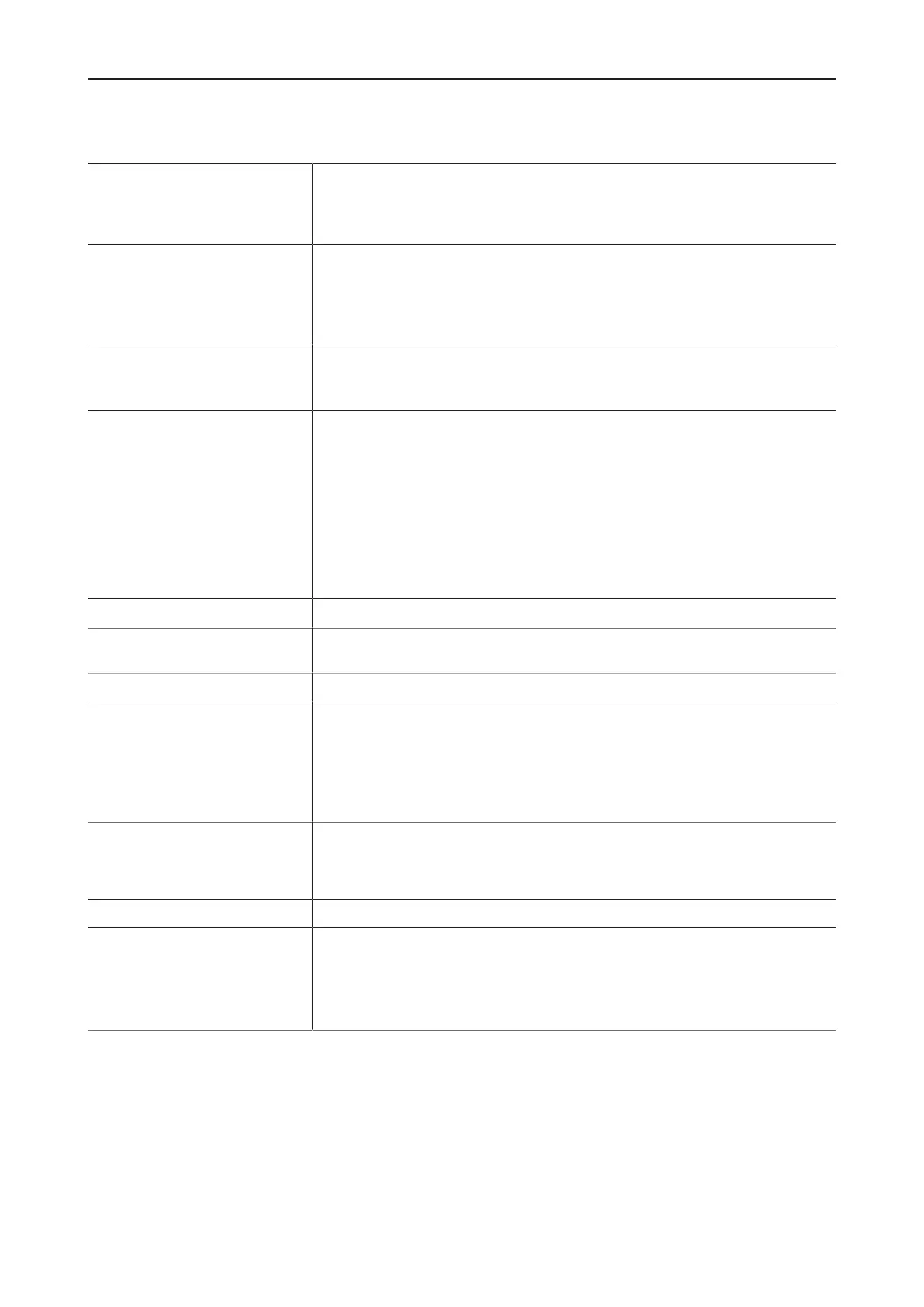

7.1 Maintenance schedule

during a shift Monitor the filling level of the grease cartridge of the ContiLube

®

II lubrication sys-

tem and immediately replace an empty cartridge.

Monitor the lubricant film on the shaft of the working tool.

Manual lubrication of the working tool approx. every 2 hours.

daily Check the bolted connections at the adapter plate and tighten as required.

Check the hydraulic lines for leaks.

Check that the pipe clamps on the carrier are tight.

Check the screw connections of the swivel joint covers and tighten as required.

Replace damaged swivel joint covers.

during and after the first 50 oper-

ating hours

Tighten the screw connections daily during the first 50 operating hours.

Replace the oil filter cartridges after the first 50 operating hours.

Check the fill pressure of the HP-accumulator during the first operating week.

weekly Visual check of the tensioning bolts through the service openings placed at the top

of the breaker box's rear side.

Check the screw connections and tighten as required.

Check the pins in the retainer bars.

Check that the plugs of the retainer bars are in place and are not damaged. Re-

place any damaged plugs.

Check the adapter plate and the breaker box for cracks.

In normal use: Clean and grease the DustProtector system.

Check the connecting fittings of the ContiLube

®

II system for leaks.

Visual check of the HP-accumulator.

monthly Check the pressure in the piston accumulator.

after the first three operating

month

Check the fill pressure of the HP-accumulator.

every 500 operating hours Check the oil filter and replace as required.

when replacing the working tool,

and at least every 100 operating

hours

Check the working tool for wear.

Check the lower and upper wear bush for wear.

Check that the piston impact surface is not chipped.

Check that the working tool impact surface is not chipped.

Check the working tool for burrs.

Check the retainer bar for burrs.

when performing regular replace-

ment of all hydraulic breaker

seals, and at least every 1000

carrier operating hours

Replace the o-rings on the fastening screws of the HP-accumulator.

annual Check the fill pressure of the HP-accumulator.

if necessary Replace bent and damaged pipes.

Replace damaged hoses.

Check the pressure in the piston accumulator.

In case of dusty conditions: Clean and grease the DustProtector system.

Check the adapter plate bolts for wear.

Loading...

Loading...