Safety and operating instructions

42 © Construction Tools GmbH | 3390 5203 01 | 2019-08-06

Original Instructions

the shut-off valves or disconnect the quick-release

couplings, so that no hydraulic oil can flow back from

the carrier.

7.3 Cleaning

NOTICE Environmental damage due to polluted water

Hydraulic oil and chisel paste are environmentally harm-

ful and must not penetrate the ground or enter the water

table or water supplies.

u Collect the water used for cleaning if it has been con-

taminated by hydraulic oil and chisel paste.

u Dispose of the water in accordance with the applica-

ble regulations to avoid environmental hazards.

7.3.1 Preparations

Hydraulic breaker installed:

n

Place the breaker on the working tool and exert a

slight pressure.

This prevents water penetrating the percussion pis-

ton.

Hydraulic breaker not installed, working tool re-

moved:

n

Plug up all hydraulic ports.

n

Seal the aperture for the working tool with the protec-

tive cap.

7.3.2 Procedure

NOTICE Damage to the hydraulic breaker

Water can penetrate the percussion chamber via the

percussion chamber ventilation non-return valve. This

may cause the percussion piston to rust which may re-

sult in damage to the seals and the cylinder.

u Never direct the pressure cleaner jet onto the per-

cussion chamber non-return valve.

n

Use a pressure cleaner to remove dirt from the hy-

draulic breaker.

7.4 Lubrication

7.4.1 Checking the lubricant film

The lubricant film on the shaft of the working tool must

be checked during the work shift.

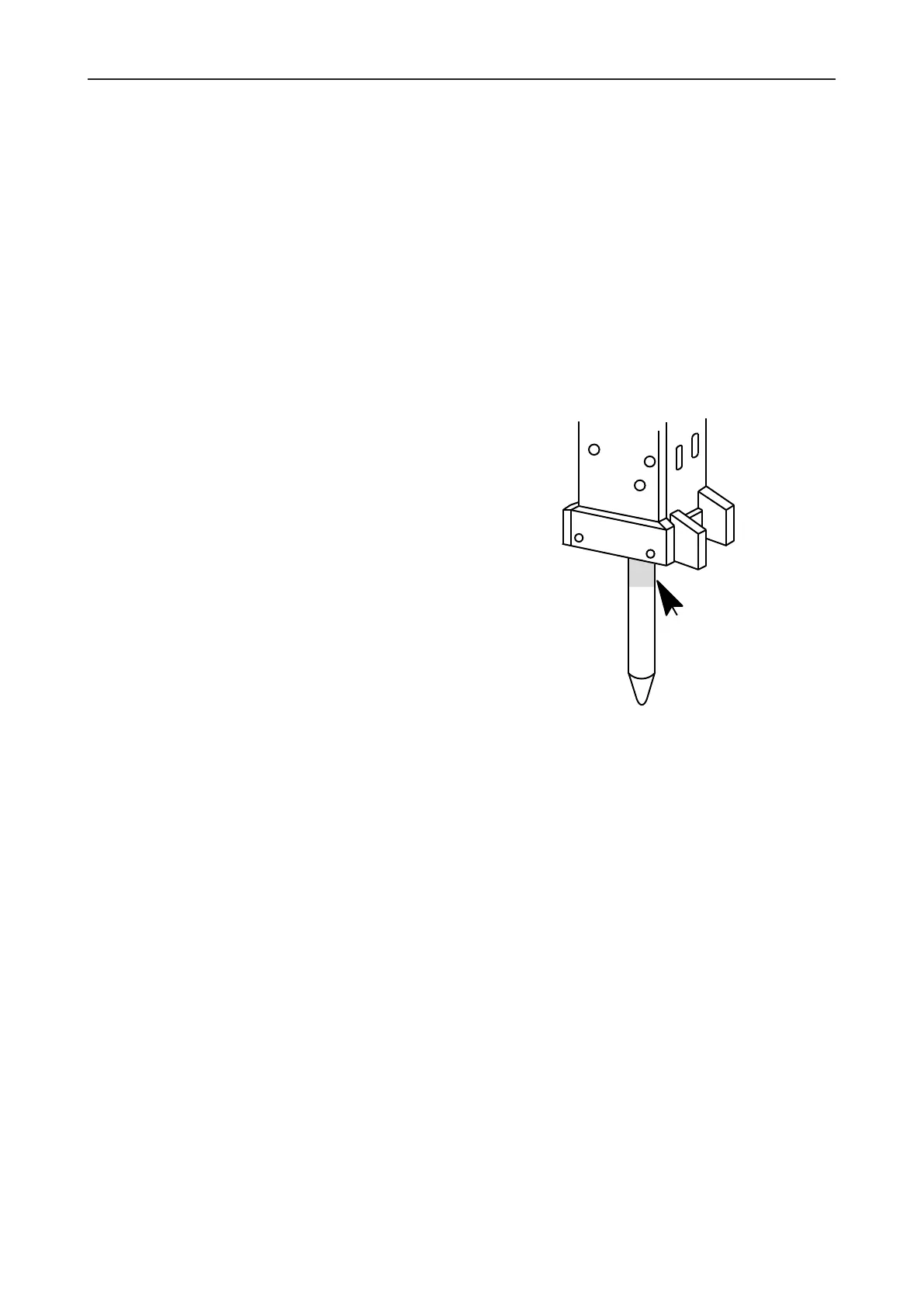

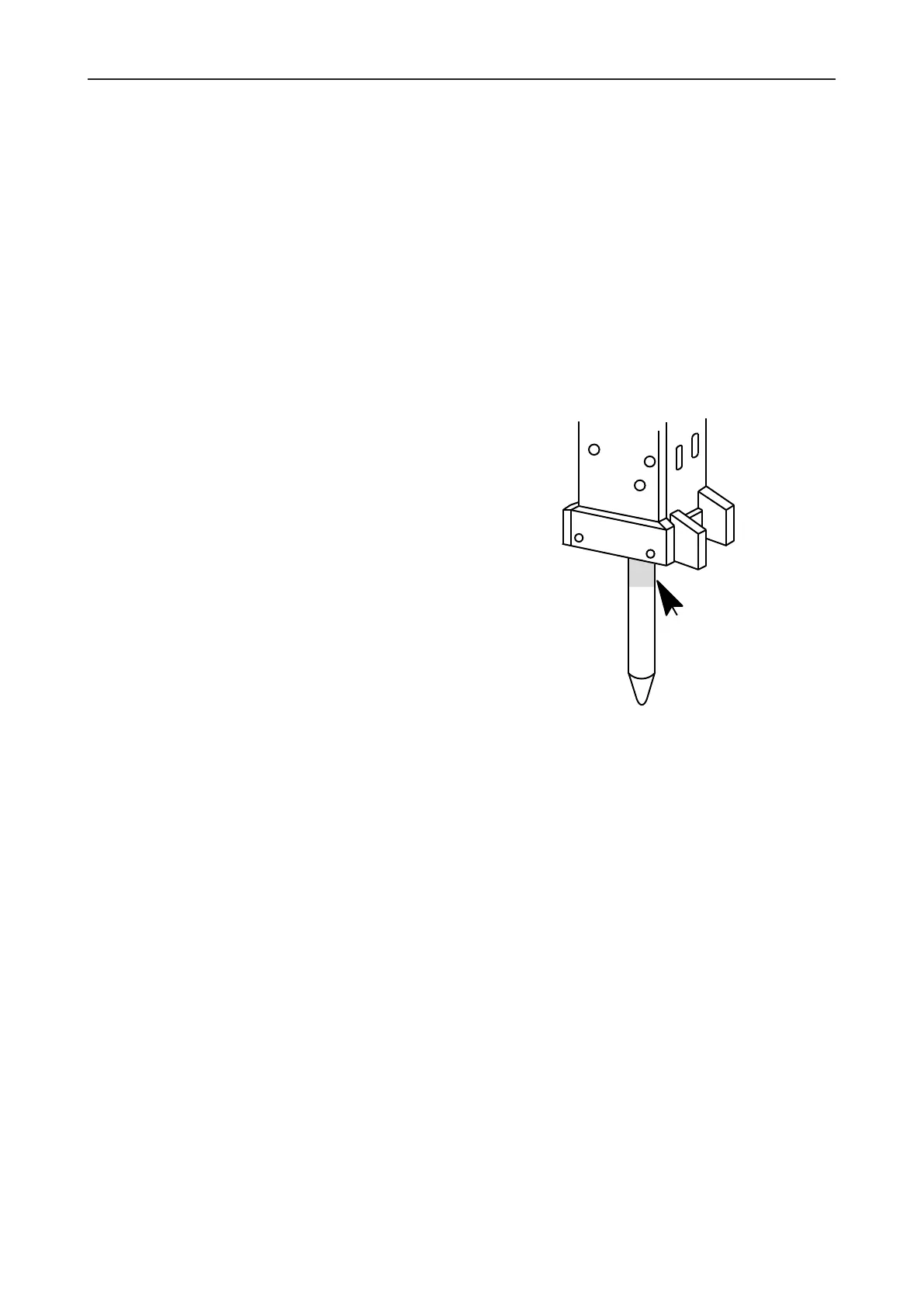

n

Let the hydraulic breaker hang freely from the carrier

boom.

When the working tool is hanging from the retainer bars,

the lubricant film on the shaft of the working tool be-

comes visible. There must be an even film of lubricant

on the entire shaft.

n

Increase the lubricant supply if the film of lubricant

comes away or dry spots can be seen:

–

Automatic lubrication: increase the lubricant sup-

ply via the metering screw of the ContiLube

®

II.

–

Manual lubrication: increase the lubrication inter-

val and the number of strokes from the manual

grease gun.

NOTICE Damage due to excessive lubrication

Excessive lubrication may damage the hydraulic breaker

and the carrier. The impact surface of the working tool

must be free of grease.

u Do not over-lubricate the working tool.

If the ContiLube

®

II automatic lubrication system has

been installed, a lubrication pulse is triggered whenever

the hydraulic breaker is switched on.

n

Adjust the lubricant supply to your work method.

Loading...

Loading...