Safety and operating instructions

© Construction Tools GmbH | 3390 5203 01 | 2019-08-06

Original Instructions

51

n

Close the pressure relief valve(D).

n

Connect the filling hose end(H) to the minimess con-

nection(C) of the pressure relief valve(D).

n

Open the valve of the nitrogen bottle(F).

n

Remove the threaded plug(A) from the filling

valve(G).

n

Push the free filling hose end(H) into the filling

valve(G).

n

Slowly open the pressure relief valve(D) to let the ni-

trogen flow into the piston accumulator.

n

Read out the pressure increase from the pressure

gauge(B).

n

Close the pressure relief valve(D) when the piston

accumulator has reached the required pressure

+10%.

n

Pull the filling hose out of the filling valve(G).

n

Check the pressure in the piston accumulator and let

gas escape until the required gas pressure has been

reached.

n

Install the threaded plug(A) in the filling valve(G)

and tighten it to the required tightening torque (see

chapter Bolt connections / Tightening torques).

n

Close the nitrogen bottle valve (F).

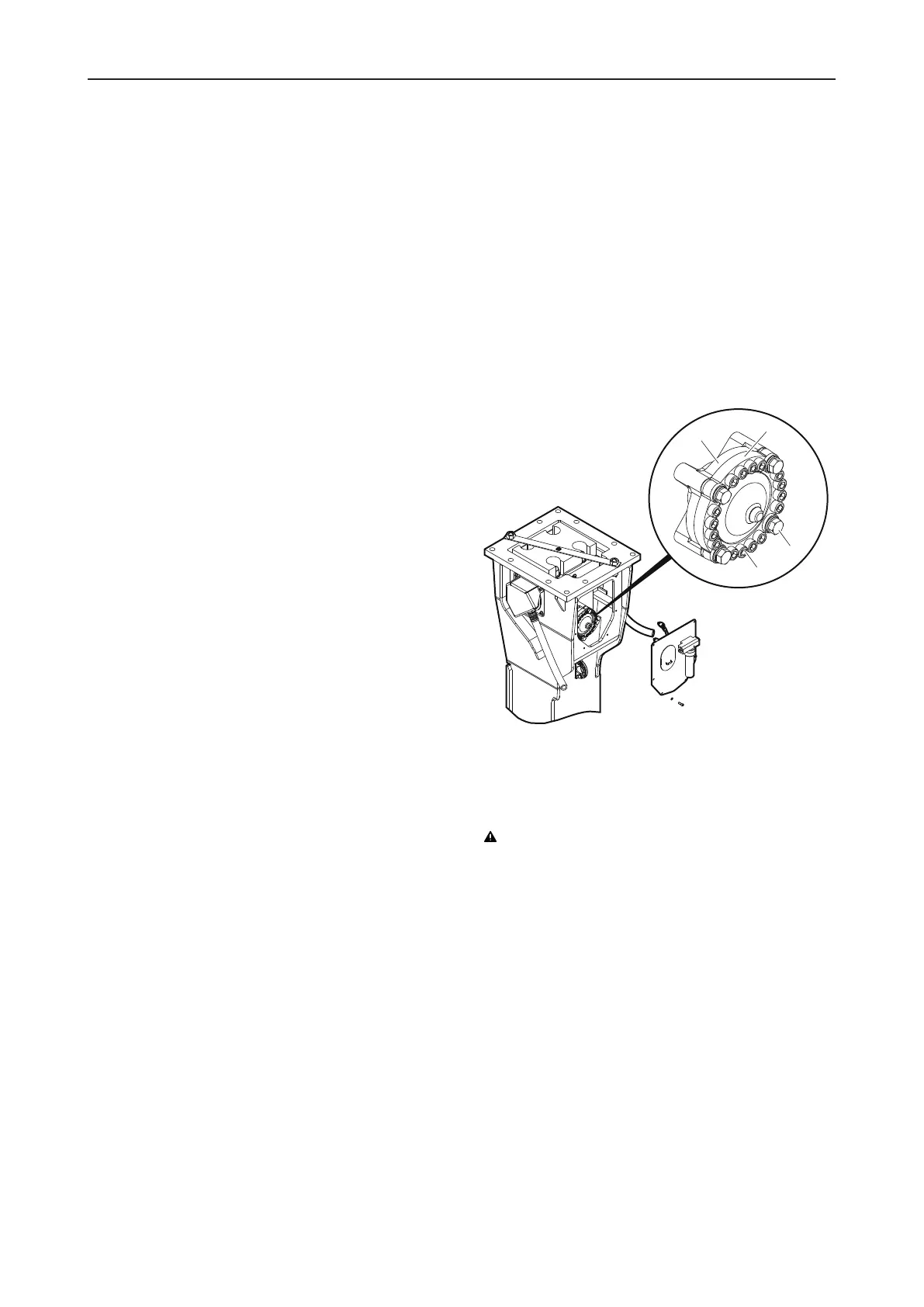

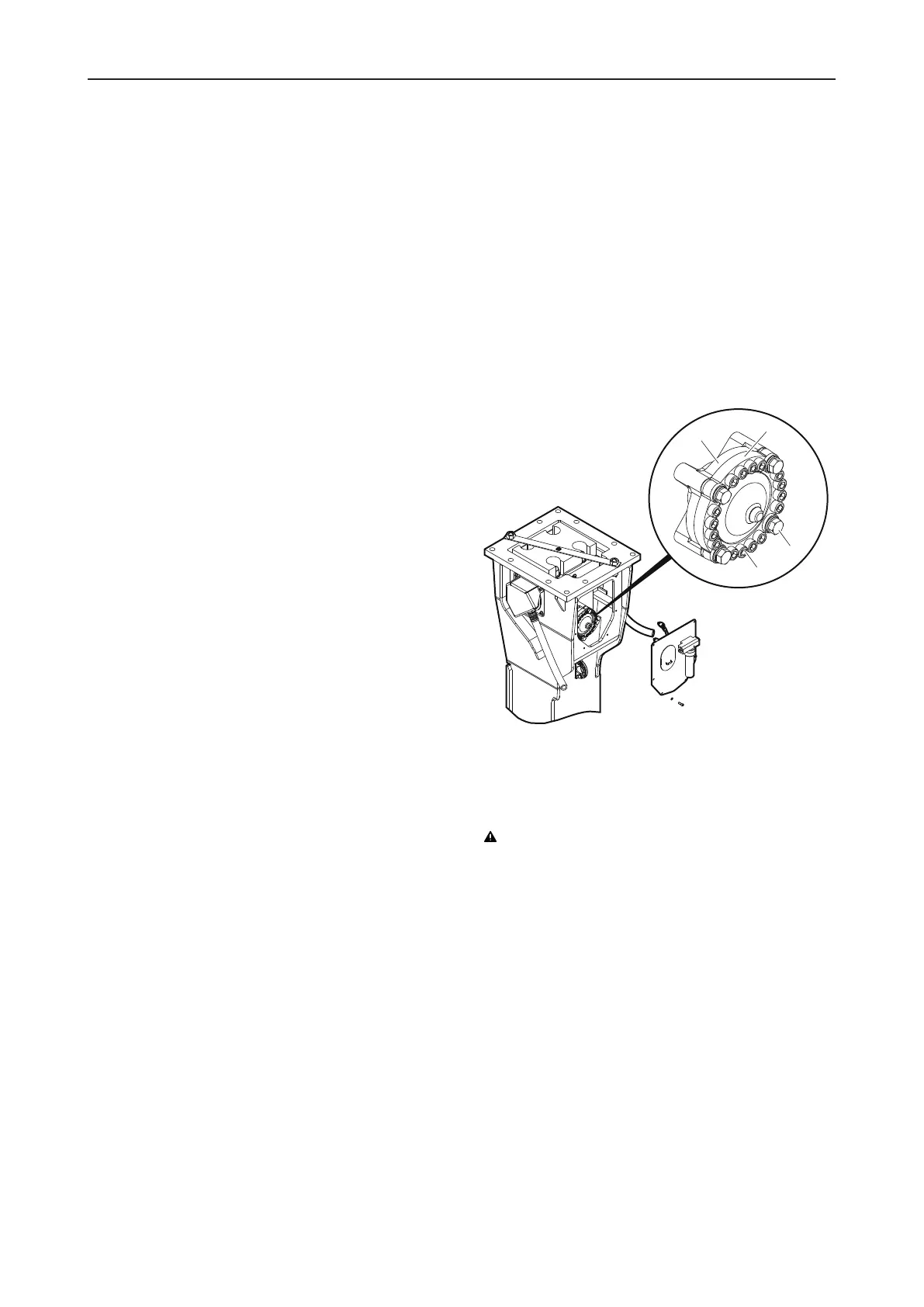

7.12 HP-accumulator

Accumulators are pressure containers in the context of

the European Pressure Equipment Directive 2014/68/

EU.

As safety−related components, high pressure accumula-

tors are subject to special safety regulations.

Overhauling high pressure accumulators is only permit-

ted if carried out by professionals. Professionals are

people who are authorised to overhaul high pressure ac-

cumulators according to national regulations.

Contact the Epiroc Customer Center / Dealer in your

area for a professional.

A. Lower shell

B. Upper shell

C. Fastening screws

D. Connecting screws

WARNING Component coming loose abruptly

The HP-accumulator is under pressure, even when the

hydraulic system has been depressurised. Screw con-

nections and parts of the HP-accumulator might come

loose abruptly and cause injuries.

u Never unscrew the cover or the upper shell from a

pressurised HP-accumulator.

u Have the HP-accumulator checked in accordance

with the national / regional safety provisions.

7.12.1 Visual check

Once a week carry out a visual check of the HP-accumu-

lator.

In case of damages, safe, trouble-free operation is en-

sured only if the complete HP-accumulator is replaced.

Loading...

Loading...