Instruction Manual

D103409X012

Detailed Setup

May 2013

72

D For instruments with Relay B: If decreasing air pressure at output B causes the magnet assembly to down, or the

rotary shaft to turn clockwise, enter CW/To Bottom Inst. If it causes the magnet assembly to move up, or the rotary

shaft to turn counterclockwise, enter CCW/To Top Inst.

View / Edit Feedback Connection—Refer to table 4‐8 for Feedback Connection options. Choose the assembly that

matches the actuator travel range.

Note

As a general rule, do not use less than 60% of the magnet assembly travel range for full travel measurement. Performance will

decrease as the assembly is increasingly subranged.

The linear magnet assemblies have a valid travel range indicated by arrows molded into the piece. This means that the hall sensor

(on the back of the DVC6200 housing) has to remain within this range throughout the entire valve travel. See figure 2‐2. The linear

magnet assemblies are symmetrical. Either end may be up.

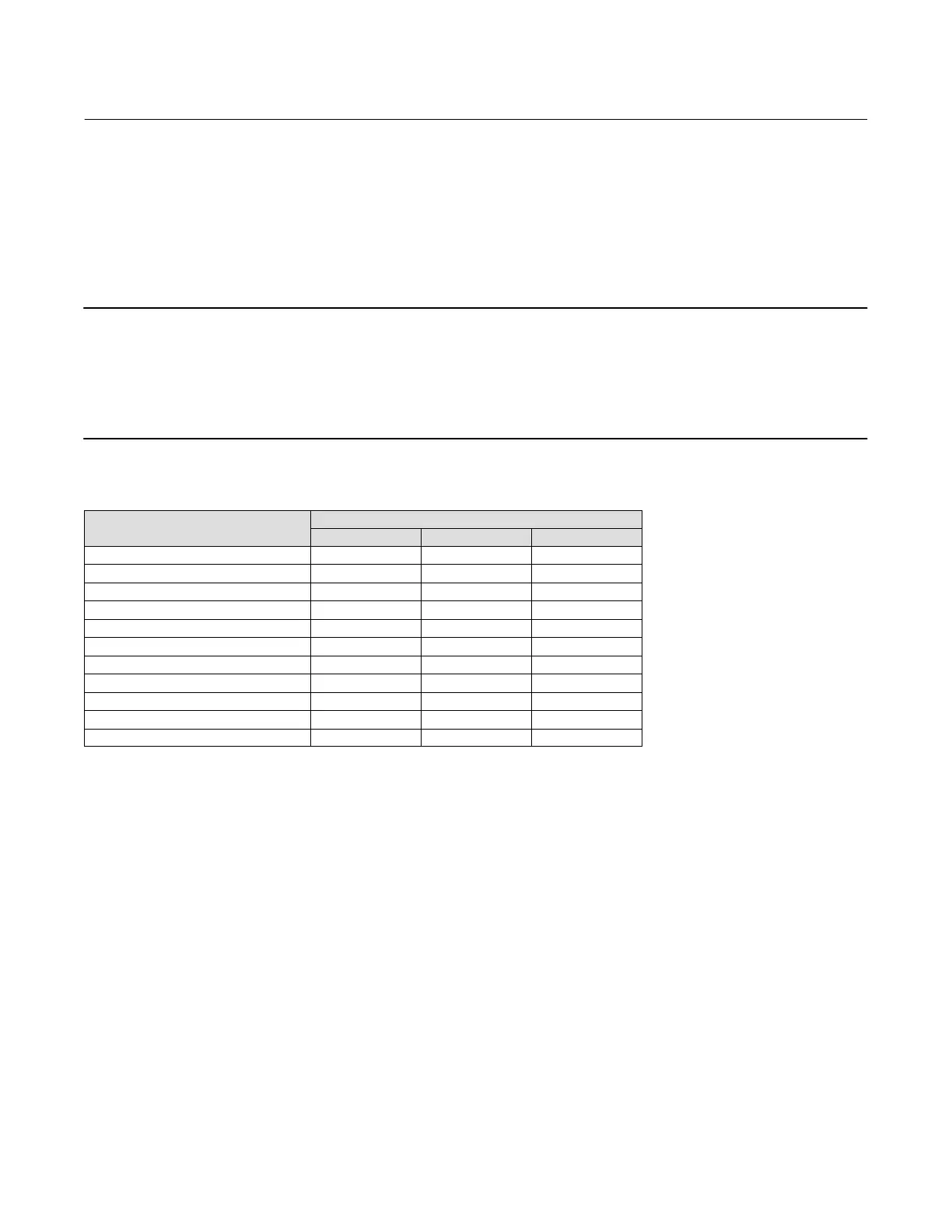

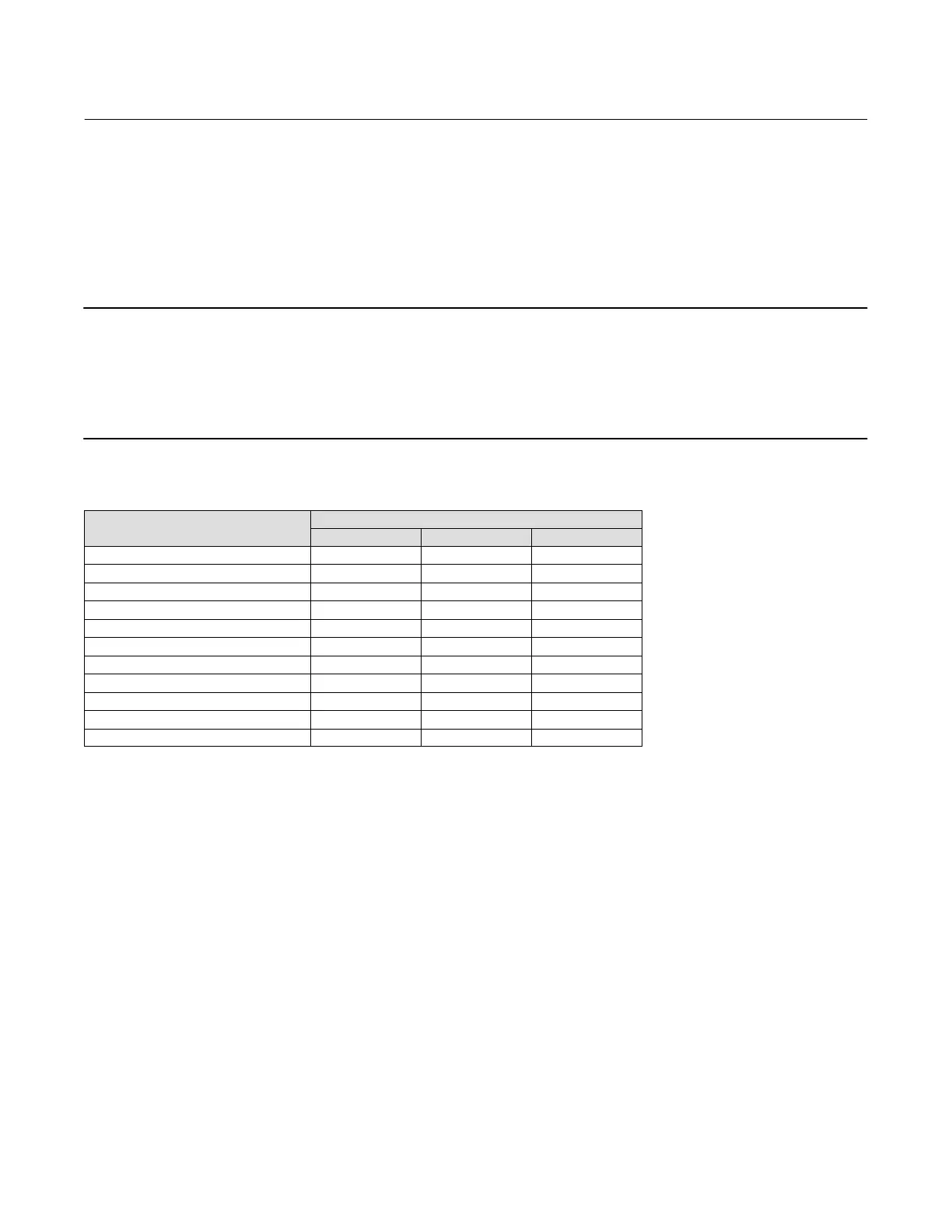

Table 4‐8. Feedback Connection Options

Magnet Assembly

Travel Range

mm Inch Degrees

Sstem #7 4.2-7 0.17-0.28 -

SStem #19 8-19 0.32-0.75 -

SStem #25 20-25 0.76-1.00 -

SStem #38 26-38 1.01-1.50 -

SStem #50 39-50 1.51-2.00 -

SStem #100 51-100 2.01-4.00 -

SStem #210 101-210 4.01-8.25

SStem #1 Roller - - 60-90_

RShaft Window #1 - - 60-90_

RShaft Window #2 - - 60-90_

RShaft End Mount - - 60-90_

Assembly Specification Sheet— Allows you to view and edit the Specification Sheet used by ValveLink software.

Loading...

Loading...