26

VRD: safety func-

tion

A Voltage Reduction Device (VRD) is an optional safety device for reducing the voltage. It

is recommended for environments in which the risk of an electric shock or electrical acci-

dent is increased considerably during arc welding:

- Due to a low human body resistance of the welder

- If the welder is exposed to a clear risk of touching the workpiece or other parts of the

welding circuit

A low human body resistance is possible when there is:

- water in the area

- humidity

- heat, particularly ambient temperatures in excess of 32°C (89.6°F)

In wet, damp or hot locations, humidity or sweat can significantly reduce the skin resistance

and the insulation resistance of protective equipment and clothing.

Such environments can include:

- Temporary dams for draining certain areas of a site during construction work (coffer-

dams)

- Trenches

- Mines

- Rain

- Areas partly submerged by water

- Spraywater areas

The VRD option reduces the voltage between the electrode and the workpiece. In safe

conditions, the indicator for the currently selected welding process is permanently lit. A

safe condition is defined as follows:

- The output voltage in an open circuit is limited to 35 V.

For as long as the welding operation is active (welding circuit resistance < 200 Ohm), the

indicator of the currently selected welding process flashes and the output voltage may ex-

ceed 35 V.

VRD: safety prin-

ciple

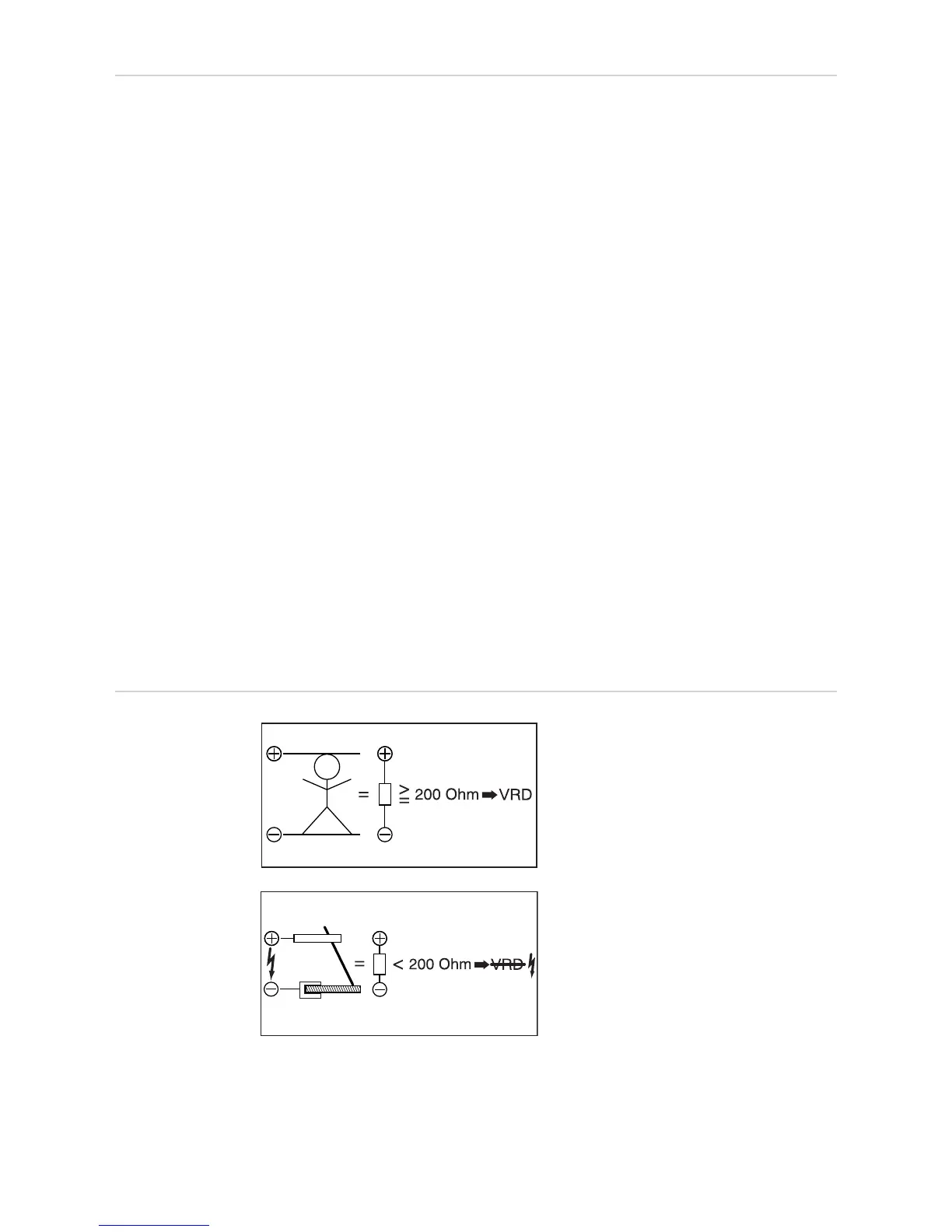

The welding circuit resistance is greater

than the minimum human body resistance

(greater than or equal to 200 Ohm):

- VRD is active

- Open circuit voltage is limited to 35 V

- Unintentional contact with the output

voltage does not put the welder at risk

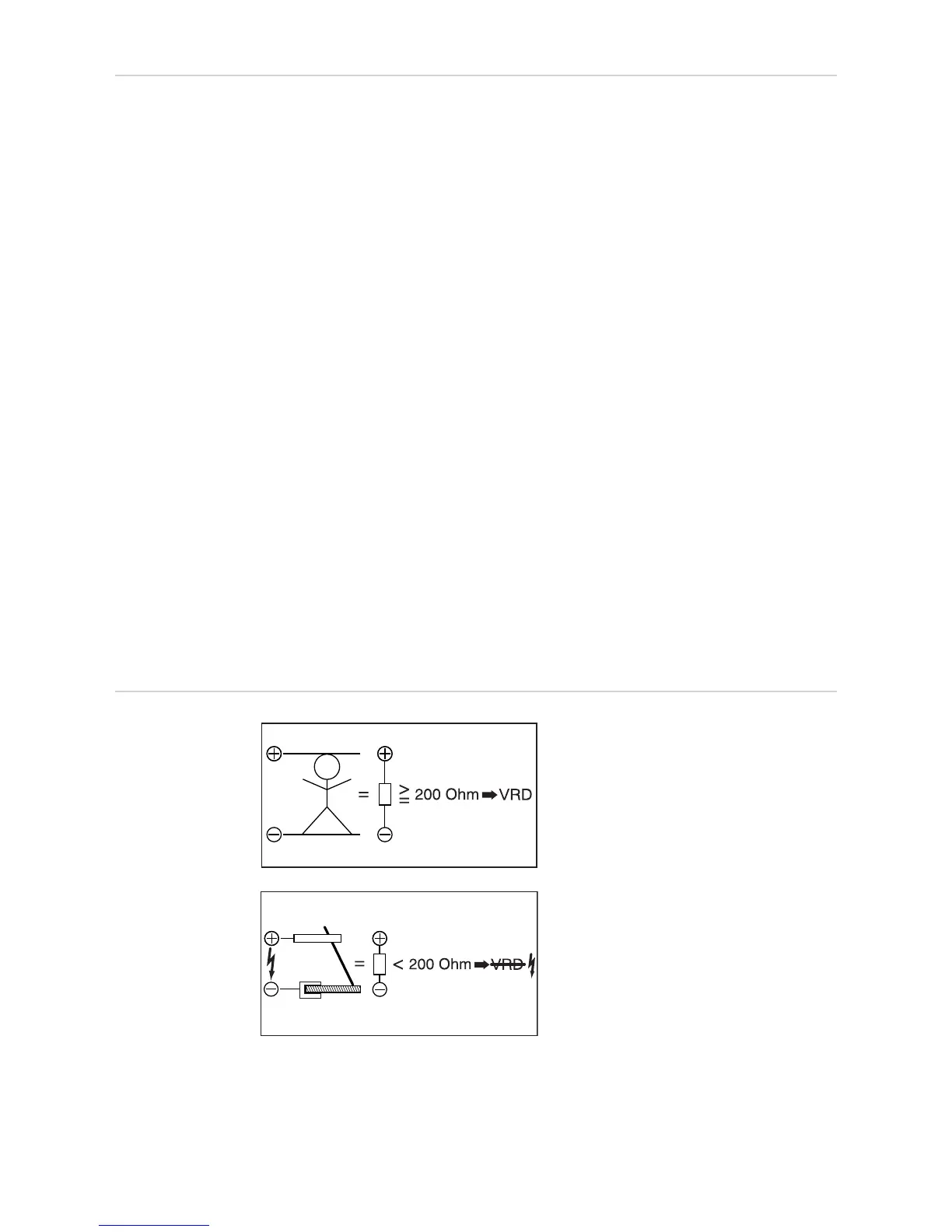

The welding circuit resistance is less than

the minimum human body resistance (less

than 200 Ohm):

- VRD is inactive

- Output voltage not restricted in order to

ensure sufficient welding power

- Example: Welding starts

In MMA welding mode:

Within 0.3 seconds of end of welding:

- VRD is active again

- The output voltage is limited to 35 V once more

Loading...

Loading...