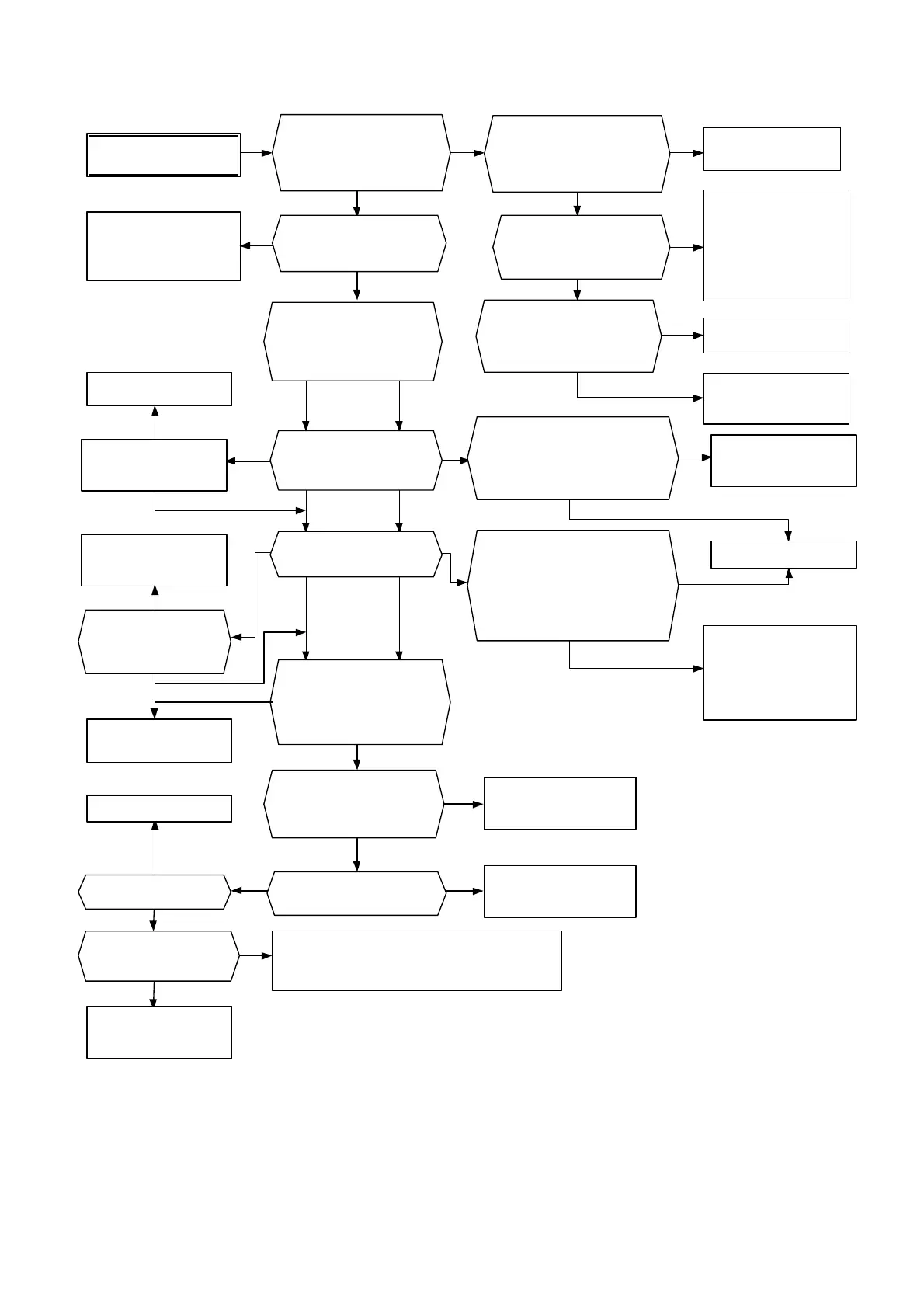

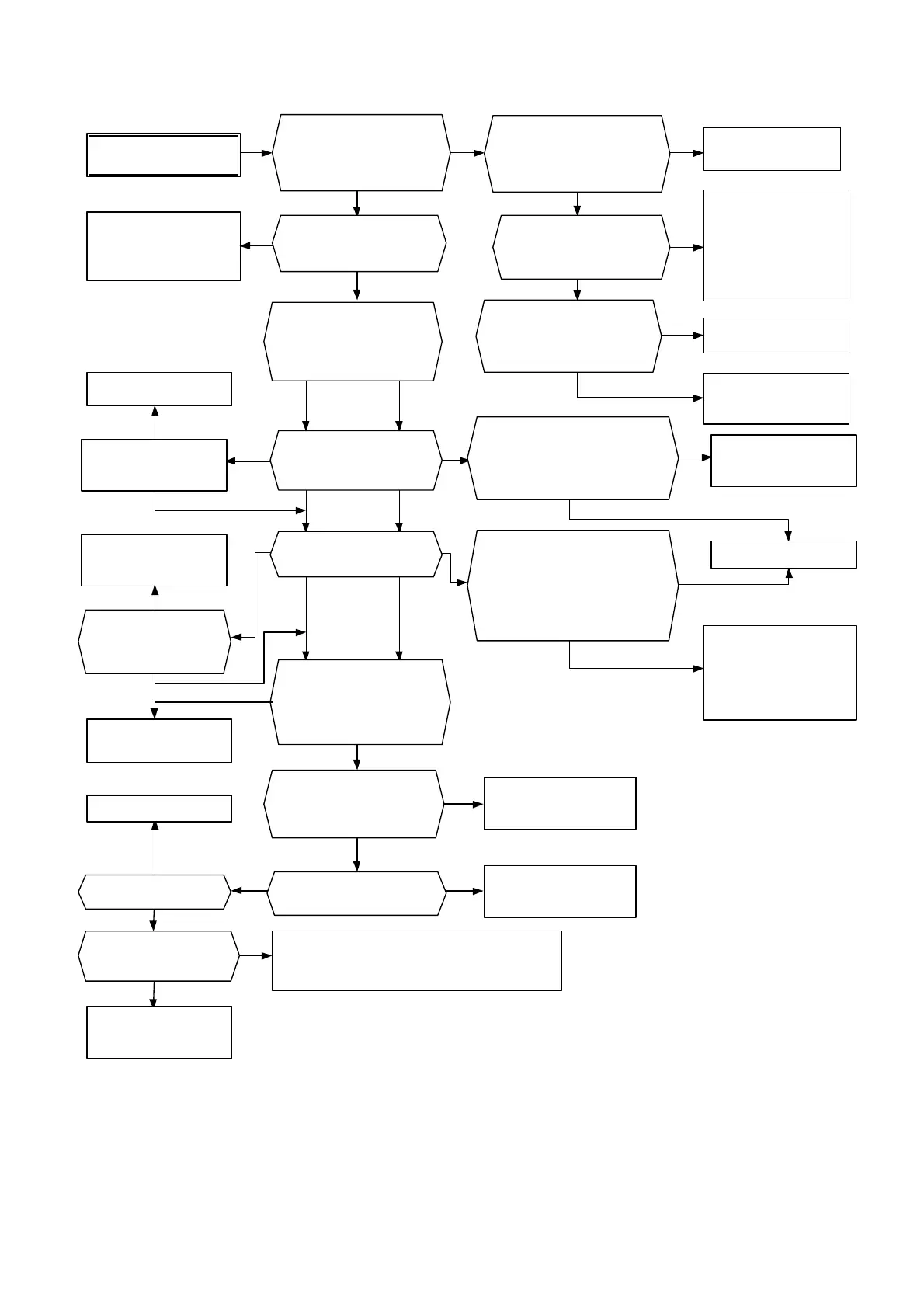

7-5

7-2 When Motor rotates Incorrectly

(1) The motor does not rotate.

The motor does not

rotate.

Remove the cause of

the alarm, reset the

alarm then start

operation.

YES

Turn them on.

Check if the charge

lamp (CRG) is lit and

that the keypad panel

displays something.

NO

Check if the alarm

mode screen is

displayed.

Check if the circuit

breaker and

electromagnetic

contactor of the power

supply are turned on.

NO

YES

YES

NO

Check if the voltage

at the power supply

terminal (R/L1, S/L2,

T/L3) is correct.

Check for voltage

drop, phase lack,

connection errors,

poor contact and

other problems and

take necessary

actions.

NO

YES

Check if the operation

commands are input

through the keypad

panel or through the

control terminals.

Check if a jumper or

DC reactor is

connected across

terminals P1 and P (+).

NO

Connect.

Continue operation if

no error is found.

Keypad

panel

Control

terminal

YES

Check if the motor

rotates when the

RUN key is pressed.

Failure of the inverter

is probable. Contact

Fuji Electric.

YES

Check if the forward

or reverse operation

command is input.

Check if the external

circuit wiring across

control terminals FWD and

REV and the CM terminal

is connected correctly.

NO

NO

YES

The switch or relay is

faulty; replace the

faulty parts.

Press the up or down

key to set the

frequency.

Check if the

frequency is set.

Check if control terminals

13, 12, 11 and C1 or, with

multistep frequency

selection, external circuit

wiring across X1 to X5 and

the CM terminal is

connected correctly.

Correct the wiring.

YES

YES

NO

NO

YES

Check if the motor

rotates when the

up or down key is

pressed.

Check if the upper

frequency limiter and

the set frequency are

smaller than the

starting frequency.

The frequency setting

unit, signal converter,

switch, relay contact or

other unit is faulty.

Replace the faulty

parts.

YES

Check that the

voltage is present at

the inverter output

terminals (U, V, W).

Check if the wiring to

the motor is correct.

Set the correct

frequency.

Failure of motor.

Increase the torque

boost amount.

Check if the load

is excessive.

Check if the torque

boost amount is

correctly set.

YES

YES

NO

NO

NO

NO

YES

NO

NO

Failure of the inverter

is probable. Contact

Fuji Electric.

YES

Correct the wiring.

NO

NO

YES

Note: For the

operation command

frequency setting

and other data,

select each function

and monitor at the

keypad panel.

YES

YES

The load is excessively large and the motor is

locked. Reduce the load. For motors with a

mechanical brake, check that the brake is

released.

NO

The motor does not start when a coast-to-stop command or DC braking command is being input.

P24

Loading...

Loading...