6. SYSTEM DESIGN

PIPING DESIGN2.

IMPORTANT ITEMS WHEN USING REFRIGERANT R410A2-1.

R410A operates at higher pressure and has less solubility with mineral oil than

traditional R22 refrigerant. Therefore, the lubricant and a part of pipe material are different.

Some special tools are necessary.

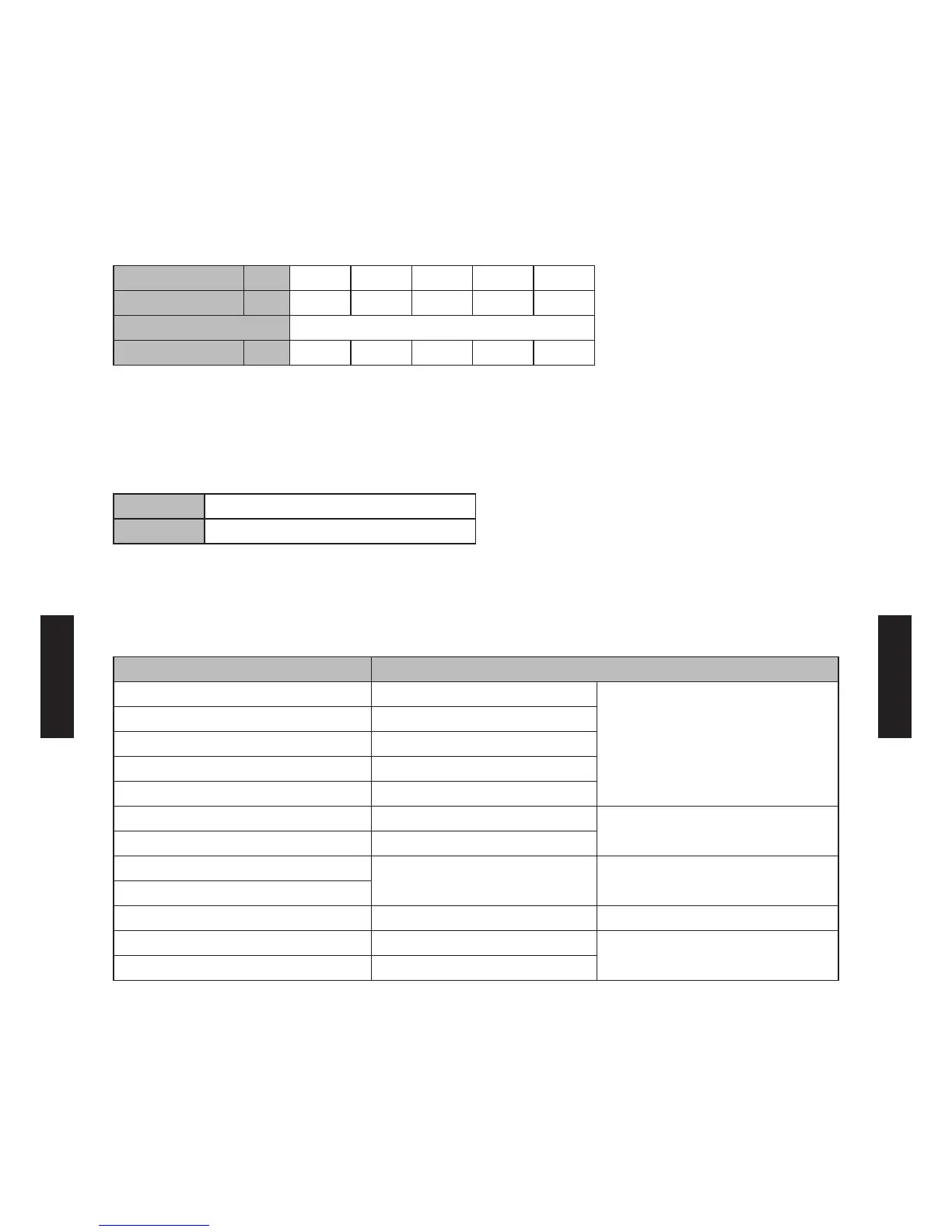

REFRIGERANT PIPING MATERIAL AND WALL THICKNESS

It is necessary to use seamless copper tubes for refrigerant use.

Thickness of tubes are shown in table below.

Endurance pressure of the pipe must be 4.2 MPa.

Nominal Diameter (in) 1/4" 3/8" 1/2" 5/8" 3/4"

Outside Diameter (mm) 6.35 9.52 12.70 15.88 19.05

Material JIS H3300 C1220T-O or equivalent *1

Wall Thickness *2 (mm) 0.8 0.8 0.8 1.0 1.2

owabe tensie stress

2

)

*2: Endurance pressure of the pipe must be 4.2 MPa.

Please select the pipe size in accordance with local rules.

LUBRICANT

Refrigerant R410A (Mixed refrigerant)

Lubricant Synthetic oil

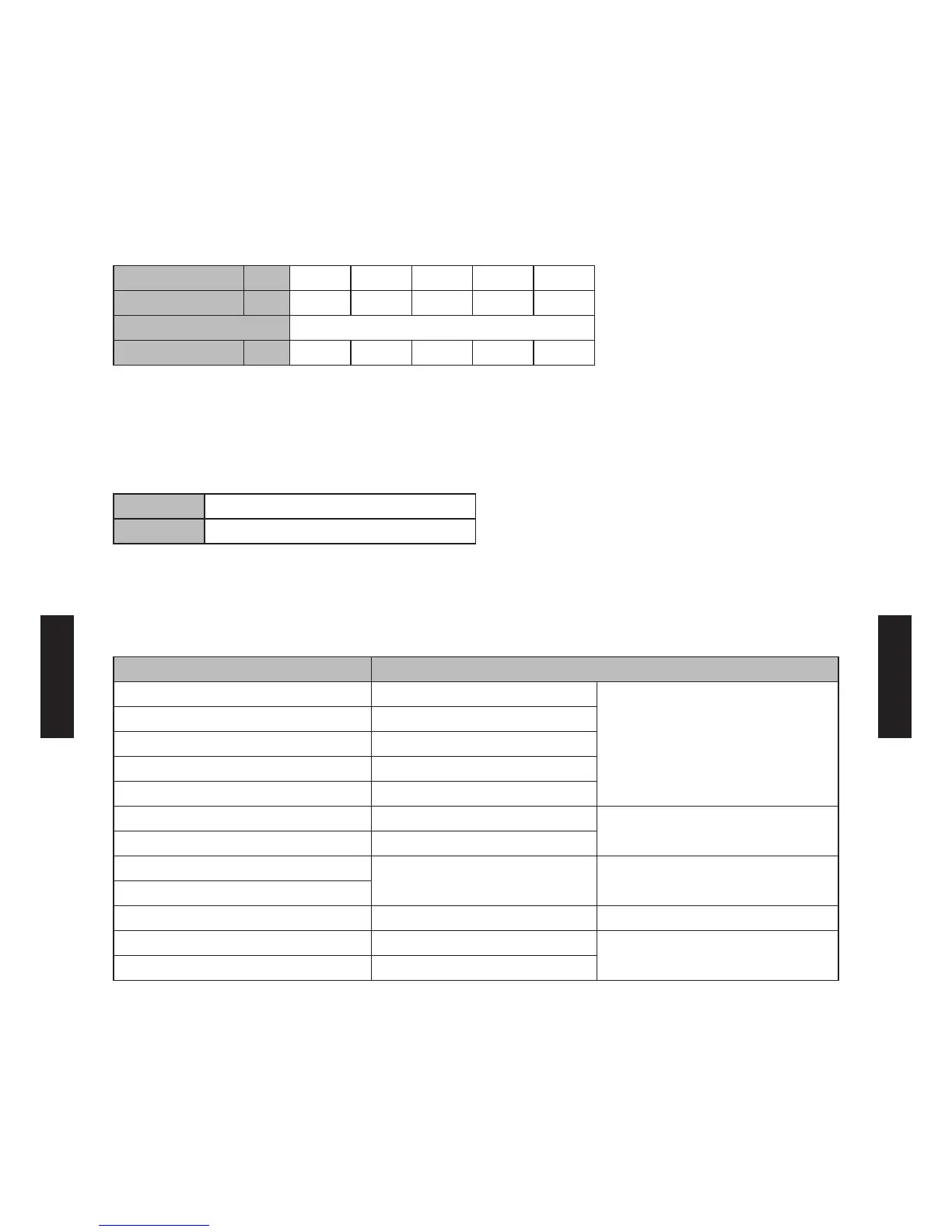

TOOLS

R410A work requires a number of special tools. Since the tools (marked *4 below) for R22

work cannot be used for R410A, prepare them beforehand.

Tool name Process and application

Pipe cutter Pipe cutting

Refrigerant piping work

Flaring tool *4 Pipe aring wor

Torque wrench *4 Flare nut connection

Expander Expansion at pipe connection

Pipe bender Pipe bending work

Nitrogen gas Pipe interior oxidation prevention

Air tightness test

Welder Pipe brazing

Gauge manifold *4

Vacuum evacuation and refrigerant

charging Operation check

Air tightness test ~

Refrigerant additional charging

Charging hose *4

Vacuum pump (with adaptor) *4 Vacuum drying

Electronic scale for refrigerant charging

Refrigerant additional charging

Gas leak tester *4 Gas leakage test

*4: Please refer to the service manual for details.

- (06 - 11) -

SYSTEM

DESIGN

SYSTEM

DESIGN

Loading...

Loading...