1.

Screw

.

2.

Stationary

Arcing Contact -

3.

Pin

(Stationary

Arcing

Contact)

4.

Movable

Arcing

Contact

5.

Spring

(Leaf Contact) _

5A.

Stationary

Intermediate

Contact

6. Movable Main Contact ·

.

7.

Shouldered

Pin

1

2

3

4

Low Voltage

Power

Circuit

Breake~s

GEK-7303

-

28

·

~

---------

27

26

8.

Pin

(Arcing Contact Links)

5

~---t-..,,._---.....::,aa-...,

•--r--+---+----...--

22

.J.------~l

-

9.

Insulating

Link ·

.

10.

Pin

(Insulating Link)

lOA. Adjusting

Plate

5A-~--t---\----~-

______

20A

10B.

Buffer

Spacers

11.

Pin

(Side Link)

12.

Link

13.

Clevis

14.

Clevis

Pin

6

'l

8

9

___

20

~~f/r:J__..-------1~

----18

15.

Lower

Stud

16.

Pole

Unit

Base

10

-----

1-----16

·

17.

Spring

(Main Movable Contact)

18.

Pin

(Main Movable Contact) ·

lOA

____

,

19.

Pin

(Movable Arcing Contact)

20. Side

Link

- _

20A.

Contact

Stop . - · -

21.

Spring

-(Statio:f1ar.y Main Contact) - -

22 •.

Spring

(Stationary Arcing Contact)

23.

Upper

Stud -_ ·

24.

Leaf

Spring

(Stationary Main Contacts)

·

25.

Pin

(Stationary Main Contact) -

26.

Stationary

Main Contact

27 • .

screw

.

28.

Stop

=-

.:=.;,,.-i----,

{ -.

I

I

15

.

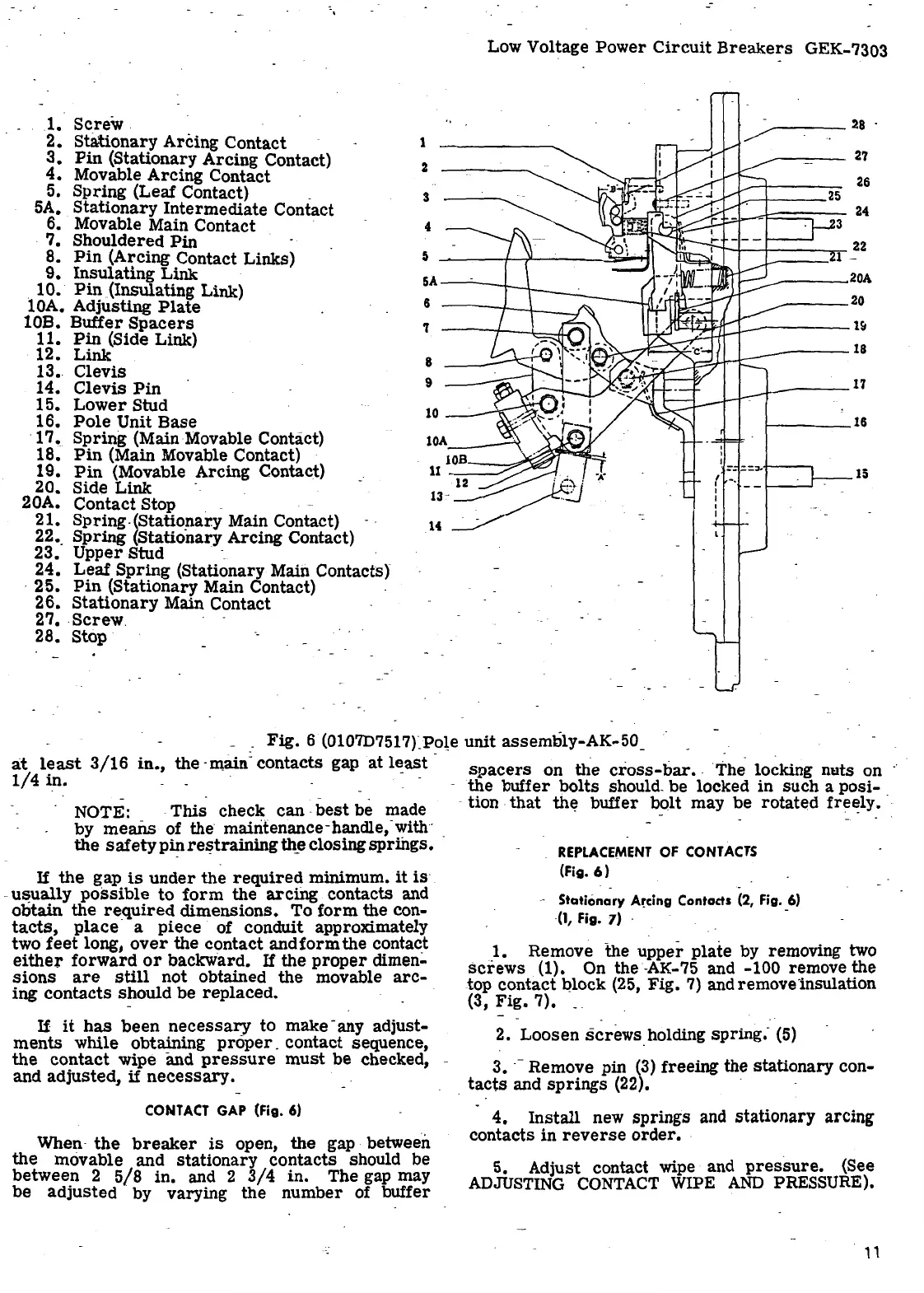

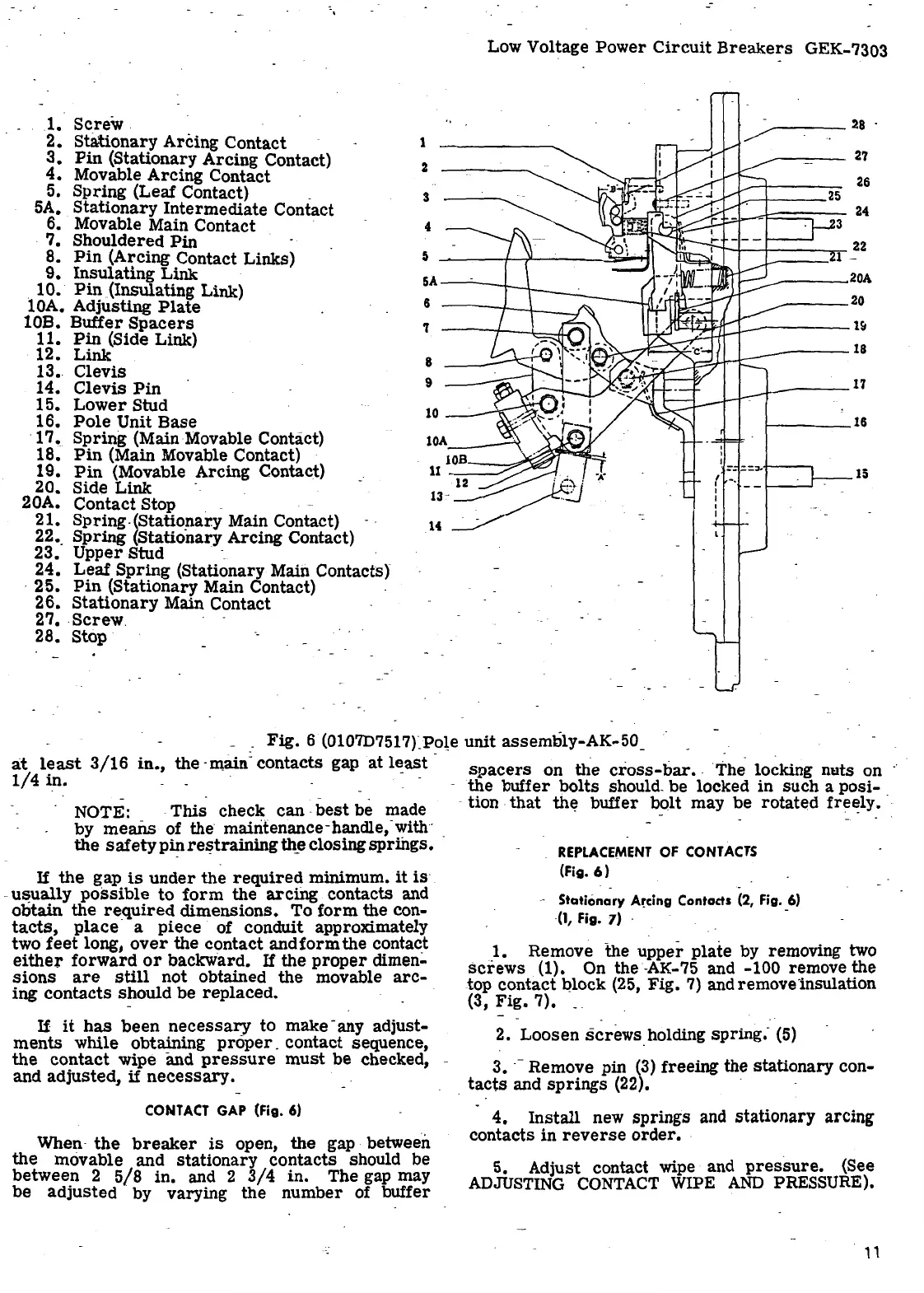

Fig.

6 (0107D7517rPote

unit

assembly-AK-50

_

a:t

least

3/16

1/4

in.

in.,

the ·main: contacts gap

at

l~ast

-

spacers

on

the

cross-bar

• . The ~ocking nuts

<?D

-

the

buffer

bolts

should.

be

locked m

such

a pos1-

- -

NOTE: -

This

check

can

.

best

be made

by

means

of the

m~~tenance

-

h~dle,-~ith

- _

the

safety

pin

rel?trammg

th_e

closing

springs.

If

the

gap

is

under

the

required

minimum.

it

is

-

usually

possible

to

form

the

arcing

contacts and

obtain

the

re_quired

dimensions.

'FO

form

~e

con-

tacts,

place

a

piece

of conchnt approximately

two

feet

long,

over

the

contact

and

form

the contact

either

forward

or

backward.

If

the

proper

dimen-

sions

-

are

still

not

obtained

the

movable

arc-

ing

contacts

should

be

replaced.

If

it

has

been

necessary

to

make -any adjust-

ments

while obtaining

proper

_

contact

sequence,

the

contact

wipe and

pressure

must

be

checked, -

and

adjusted,

if

necessary.

CONTACT

GAP

(Fig.

6)

When·

the

breaker

is

open,

the

gap -between

the

movable and

stationary

contacts

should be

between

2

5/8

in.

and 2

3/4

in.

The gap may

be

adjusted

·

by

varying

the

number

of buffer

- tion

that

th~ buffer

bolt

may

be

rotated

fre~ly.

REPLACEMENT

OF

CONTACTS

(Fig.

6)

- .

- Stationary

A~cing

Contads (2,

Fig.

_6)

(1,

Fig.

7) -

1. Remove

the

upper

plate

by removing two

screws

. (1). On the -AK-75 and -100 r~move

~e

.top

contact

Qlock (25,

Fig.

7)

and remove insulation

(3,

Fig.

7).

__

- .

2.

Loosen

screws

holding

spring.

- (5)

3 • . - Remove pin

(3)

freeing the

stationary

con-

.

tacts

and

springs

(22). · ·

4.

Install

new springs and

stationary

arcing

contacts

in

reverse

order.

·

5. Adjust contact wipe and

pressure.

(See

ADJUSTING

CONTACT

WIPE

AND

PRESSURE).

,,

Loading...

Loading...