3.

On drawout

breakers

wired

for

the fourth

gr

·ound

sensor

coil, unsolder

external

sensor

coil

leads

at

terminal

board

on

female

disconnect

plug. On

stationary

b

reak

e

rs

unsolder

twisted

shielded

pair

from

Terminal

Board

(Fi

g.

40).

4~

Remove the

four

bolts

connecting each

· coil as·sembly to the pole unit.

5. Remove the coil

assemblies

taking

care

not to damage the inter-connecting coil

wires.

· 6.

No

further

breakdown of the .coil

assem

-

blies

should

be

made. Do not

re

move the coils

from

around

their

iron

core

.

7.

· Replace coil

assemb

lies

in

revers

e

orde

r.

Sensor

Coils (Al_{-3-75/100) Only (Fig. 33)

1. Disconnect control plug between Power

Supply Unit and

Sensor

Coils.

2.

If

present,

disconnect fourth ground sensor

coil lead

as

described

in

Step 3 above.

3. Di

sconnect

·

resistor

board

from

back

frame

by removing two nuts

from

studs welded

to

back

frame.

Remove the two remaining hex head

bolts and

nuts.

Lift

board

from

the two

studs.

·

4.

Remove

collar

at

end of

primary

dis-

connects by loosening two allen head bolts and

sliding off

collar.

.~

100

0

I J J

11

I I

_I

I I

N.ONO•TIU

DELAY

Pffl~'i'!.:A0..USW11..E

0

,

,Oa,.

Tri

,.,.__.

_11

.

!!JlN~

so

200

10

0

0

~--

0

~

MAXNUM BREA!(£"

~i:::~

:,.:I''

0..£AIING•TIME

0

,

....

.....

':

~

.....

l'~

0

TI

ME AD.IUSTUL( ,

~

[-...

i~=~:.-;.s:,;1~0A

~

r::,..

z~P(C:TMl.T)ATIOO\:

~

LOIIO

I

no

c

ff

i"ir-'

l'

I

IIINIW~~

REl<T

TWt

.s

NsnJmu.rous

PIC:IM

P

SET

N

FACTORY-

i,..

4

TO"

nc

.s

.t

BRCAl«R

RA

.,

I)

z

I

.o

.o

'

f:::

~

;:

IWO-

IRCAl<[R

1/Ql'(RATIIG•

tl

MC

~

~

~

~

~

N

~

~

f;S::

~

.a

z s 4 u • io

zo

oo

ioo

aoo

CURRENT

IN

TIMES

BREAKER

RATING

Low Voltage

Power

Circuit

Breakers

GEK-7303

5. Work

coils

toward end of

stud.

Starting

with one outside pole,

slip

coils

off

stud

and

onfo

your

right

arm

or

properly

supported cyl-

inder,

now move

to

center

pole

~d

O?t side .Pole

until

coils

are

removed place

coils

with

resistor

board

on

clean

flat

su

rface.

When removing coils

from

your

arm

be careful not to

break

or

f?ul

interconnecting coil

wires.

Also note location

of

spacers.

Spaces may

vary

in thickness

their

·

purpose

is

to

space coils out .

for

a

firm

fit.

SELECTIVE

TRIPPING

.

Selective tripping

is

obtained when the

breakers

in

the

electrical

a1str1out1on

system

are

arranged

on the

basis

of a

progressive

series

of

time

avd

current

pickup.

This

will allow the

breaker

having

the

shorter

time

setting and the 1ow

er

pickup

to

trip

before the

breaker

having the lon

ger

time

setting and the higher

current

pickup, provided

the fault

is

on the ·

part

of the line

protected

by

the

breaker

having the lower setting. Hence, if

a fault

occurs

in any

part

of

the

electrical

system,

only the

breaker

nearest

the fault will

trip.

In

order

to reduce .the possibility of damaging

the

equipment and to provide maximum

safety

to

the operato

r,

the overload caused by a. fault

is

removed in a minimum amount of

time

by

se

le

c-

tive

tripping. Overloads producing

current

up

to

five

or

ten

times

the

breake

r

rating

are

removed

in

a

matter

of a

few

cycles while

currents

in

excess

of this

val

ue

are

rem

qved instantaneou

sly.

---

kJ

11111

I I I

HG

'TW[

OCI.

11

P<Cl<•UI'

ADJUST

ABU

FRO

M a

TO

1

.IT

ll<CS

8RCAl<l'.R1Up,.._

1000

soo

200

1,,1111£.

AO.N$TAIR.[ I N IM:fOrtr-

\ 1

·

so,o,.oAs

sa:ac>SUA

~

'

:g:~

~~~~

,--

" ,~

.......

I"

,-

~

100

90

zo

'\r--..:,

10

"

....

r,.,

"""""UM~

~

~TIM(

I/

I I -

--~

orl.Ar

_.,

,,__

..

,_

TA&.L

,_

'

TO

10

OESf:l'-T~

~

l'

~

~~

TNC AIWSTA81.C N -

~

,O

:~·r,;-"~~:-1~r:,

S

OR

2C:

llfSP£C:T1VII.T

>

AT

2SO\

OF

SHOAT

iifl

OCL~T

PIC:K•IP "I

~

I I

.0

.o

Tll€S IROl<ER

RATIIIG

-

~

-

"

-

~

~

---

'

~

~R

~~

~~

.,

I I ) 4

01

a

lO

tO

50

100

a11

CURRENT

IN

TIMES

BREAKER

RATING

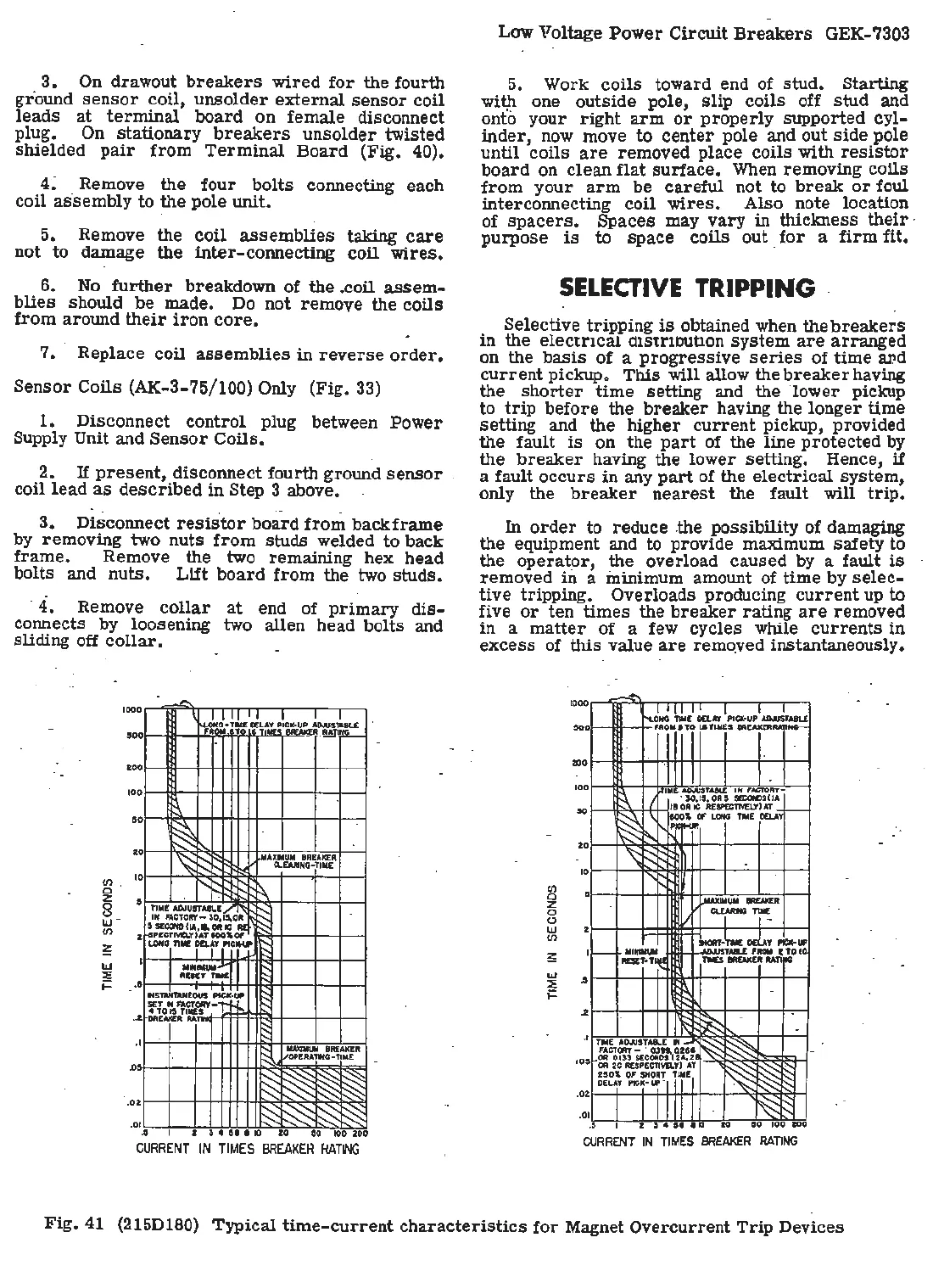

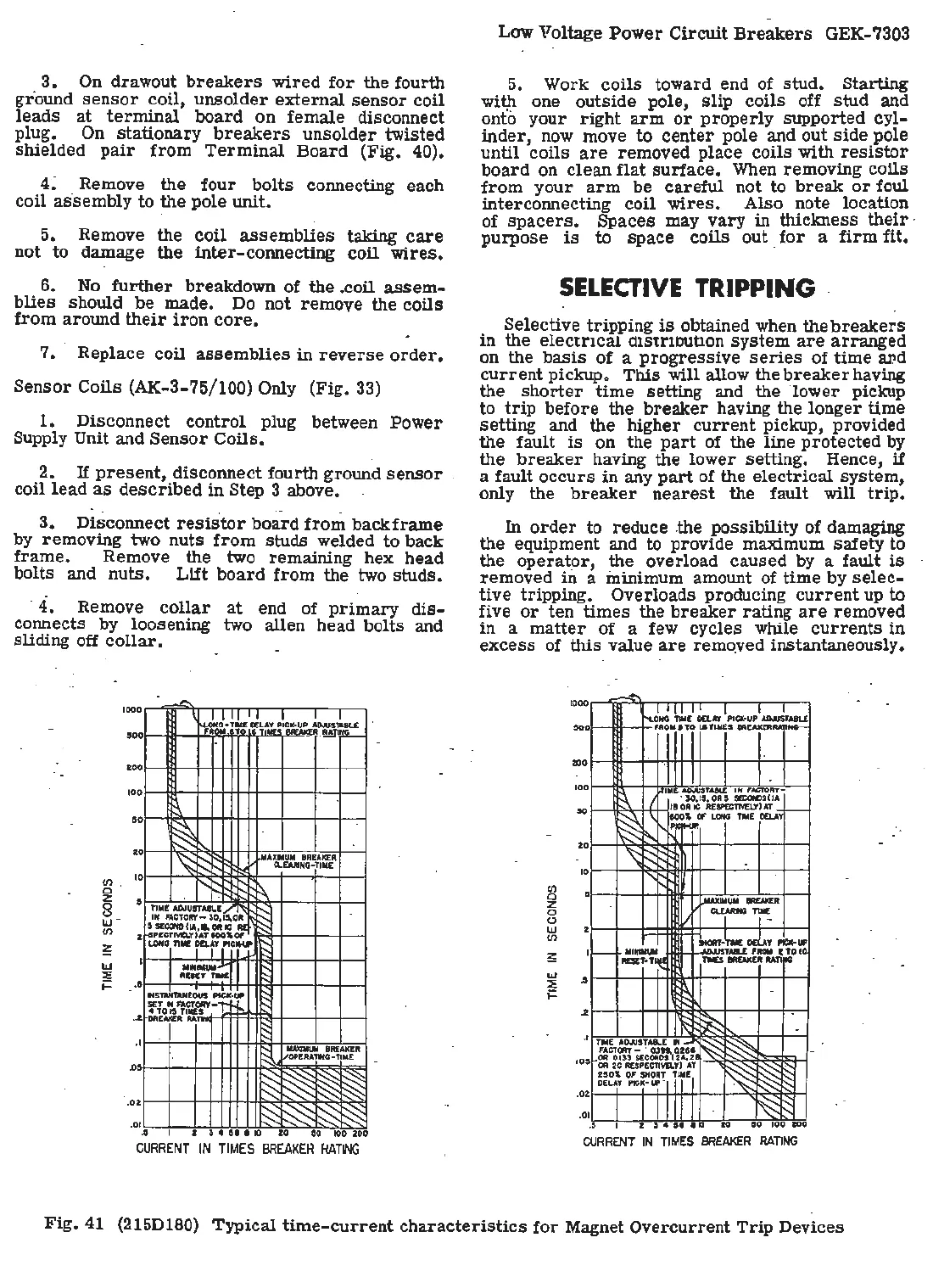

Fig

. 41 (215Dl80) Typical

time-current

characteristics

for

Magnet Overcurrent

Trip

Devices

Loading...

Loading...