Low Voltage

Power

Circuit

Breakers

GEK-7303

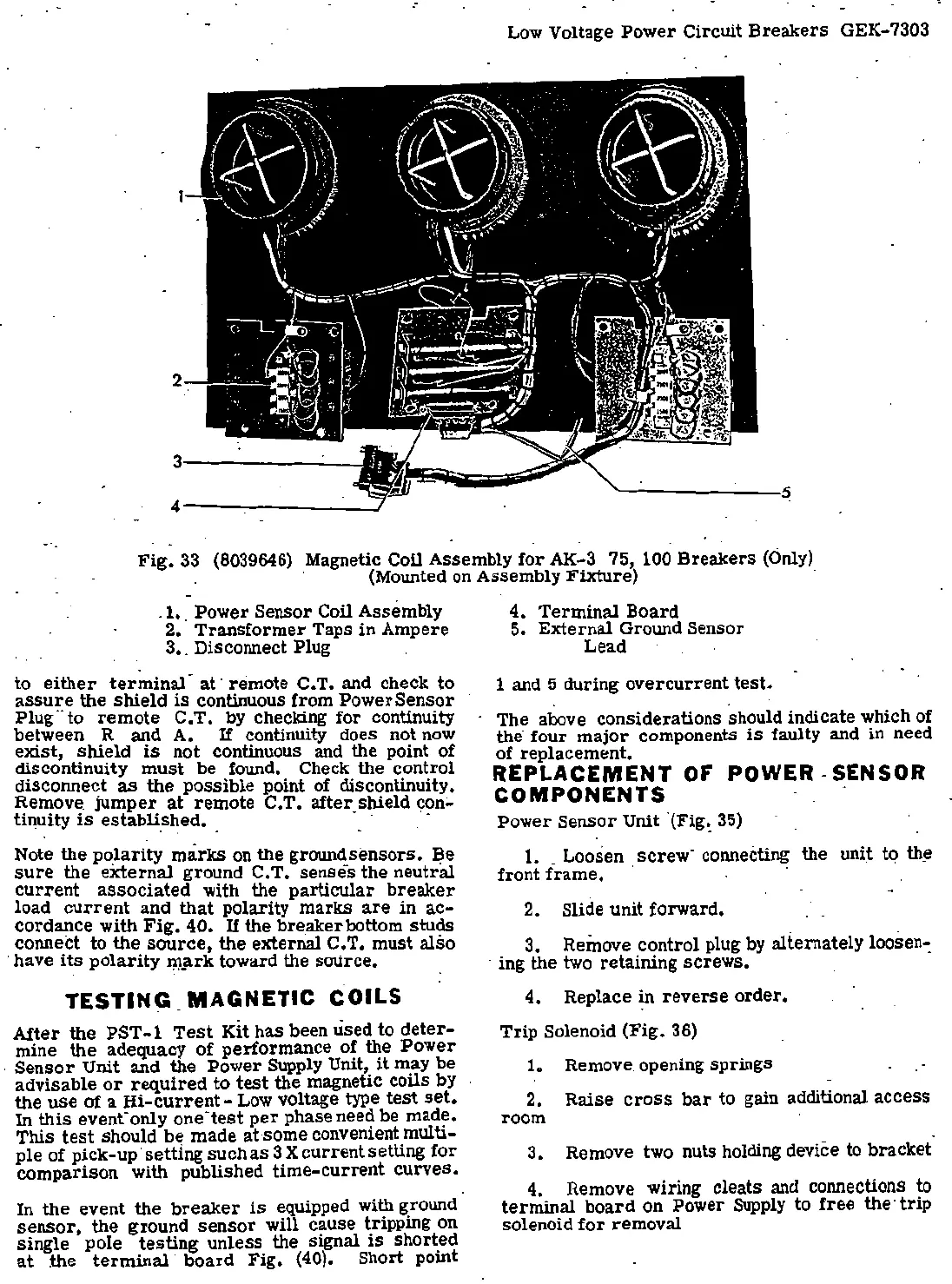

Fig.

33

(8039646) Magnetic Coil Assembly

for

AK-3 75, 100

Breakers

(Only)

· (Mounted on Assembly

Fixture)

·

.1 •.

Power

Sensor Coil Assembly

2.

Transformer

Taps in Ampere

3 •. Disconnect Plug

to

either

terminal

·

at

· remote C. T. and check to

a

ss

ure

the

shield

is

continuous from Power

Sensor

Plug

..

to

remote

C.T.

by checking

for

continuity

between R and A.

If

continuity does not

now

exist,

shield

is

not continuous and the point of

discontinuity

must

be

found~

Check the control

disconnect

as

the

possible

point of discontinuity.

Remove.

jumper

at

remote

C.T.

after

_shield

c;:on:.

tinuity

is

establi~~ed. · ·

Note the

po

_

larity

marks

on the grounc!_sensors.

~e

sure

the

external

ground C.

T.

senses

the

neutral

current

associated

with the

particular

breaker

load

current

and

that

polarity

marks

are

in

ac

-

cordance with

Fig.

40.

If

the breakerbottom

studs

connect to the

source,

the external C.T.

must

also

· have

its

polarity

~,;irk toward the source.

TESTI

N~ _

MAGNET

IC

COILS

After

the

PST-1

Test

Kit

has

been used to

deter-

mine

the

adequacy

of

perf~rmance o!

t1?e

Power

.

Sensor

Unit and the .

Power

SUpply

Unit,

it

may

be

advisable

or

required

to

test

the magnetic coils by

the

use

of a

Hi-current-

Low voltage type

test

set.

In

this

event·

on1y

one-

test

per

phase need be made.

This

t

est

should

be

made

at

·

some

convenient multi-

ple of

pick

-up·

setting

such

as

3 X

current

setting

for

comparison

with published

time

-

current

curves.

In the event

the

breaker

is

equipped with ground

sensor,

the

ground

sensor

will cause tripping on

single pole

testing

unless

the signal

is

short.ed

at

the

terminal

board

Fig.

(40)

. Short point

4.

Terminal

Board

5.

External

Ground Sensor

Lead

1 and 5 during

overcurrent

test.

. .

The above considerations should indicate which of ·

the· four

major

components

is

faulty and

in

need

of replacement.

REPLACEMENT

OF

POWER

-SENSOR

COMPONENTS

.

Power

Sensor

Unit "(Fig~

35)

1. _ Loosen

screw

· connecting the

uni~

tq th_e

front

frame.

·

2. Slide unit forward.

3 • . Remove control plug by alternately loosen-:

- ing th~ two retaining

screws.

4.

Replace

in

reverse

order.

Trip

Solenoid

(Fig.

36)

1. Remove. opening springs

2.

Raise

cross

bar

to gain additional access

room

3,

Remove two nuts holding device to

bracket

4. Remove wiring cleats and connections to

terminal

board

on Power

Supply

to

free

the·

trip

solenoid

for

removal

Loading...

Loading...