DIRECTION 5750007-1EN, REV. 1 LOGIQ E10 BASIC SERVICE MANUAL

8 - 6 Section 8-2 - Warnings and important information

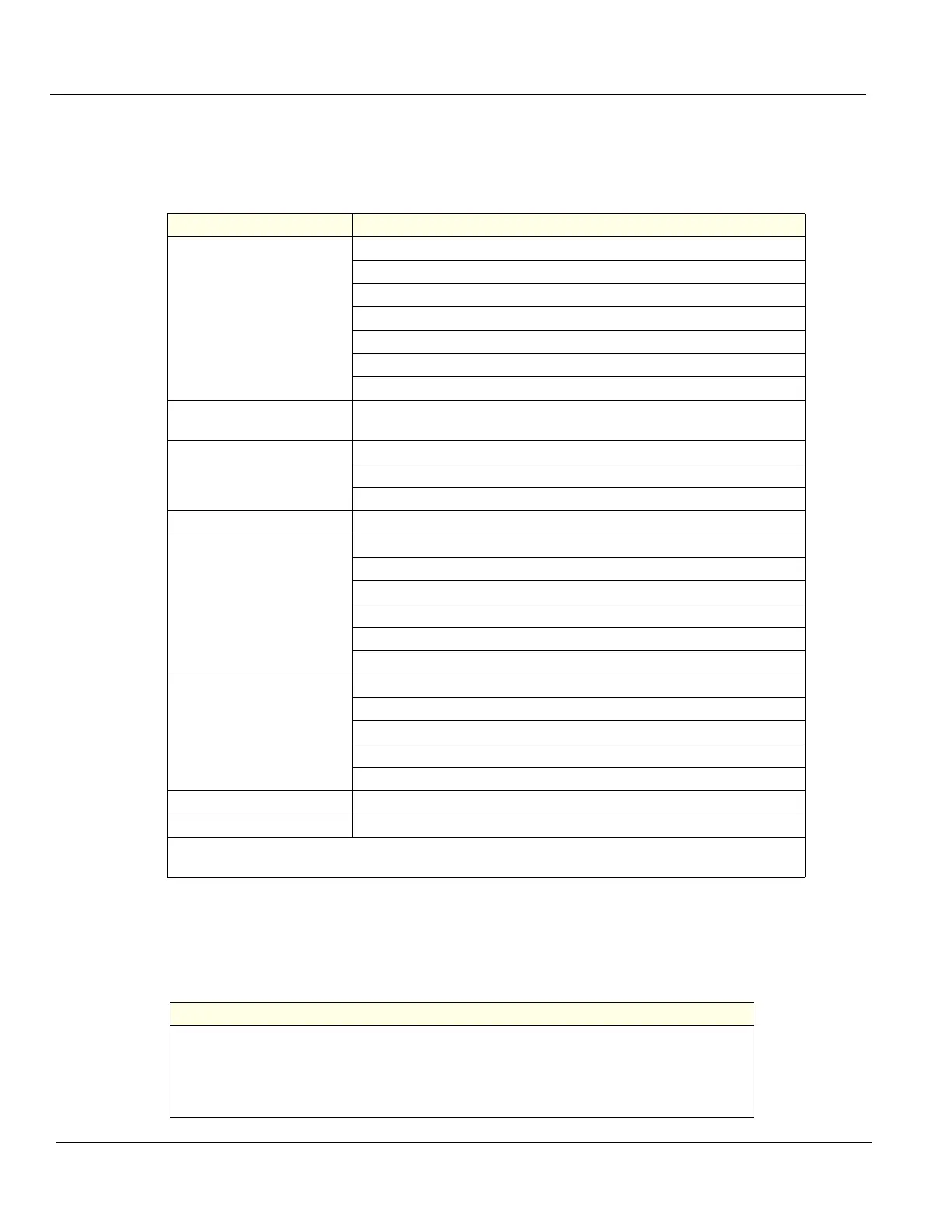

8-2-5 Tools needed for servicing the LOGIQ E10

The following tools are needed to service the LOGIQ E10. If the torque is not indicated with the

procedure, hand tighten the screws/nuts.

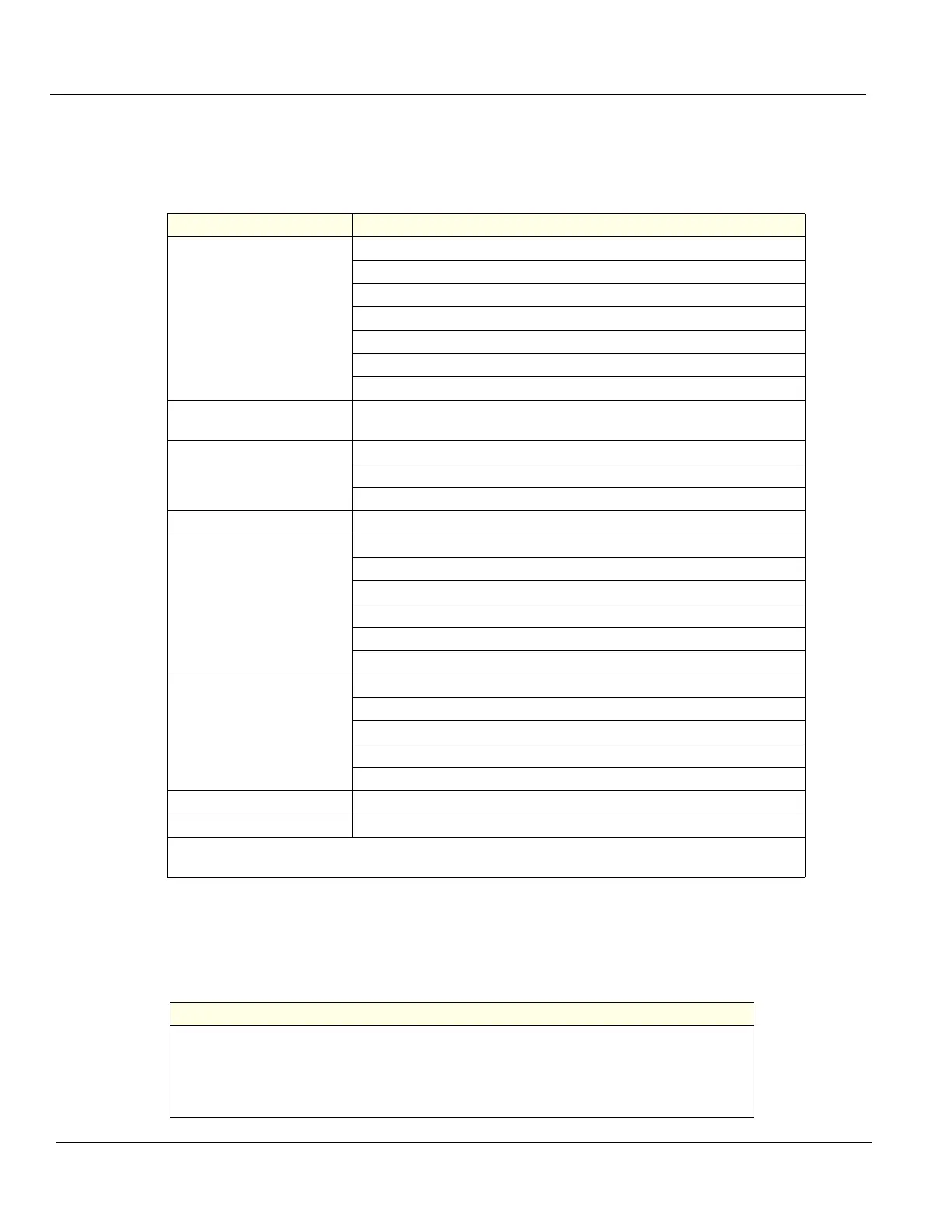

8-2-6 PPE Required During Service

The following PPE are required during service tasks, per EHS Policy:

Table 8-3 Tools used for servicing LOGIQ E10

TOOL TYPE TOOL SIZE

TORX

BIT # TX-2.8

BIT # TX-10

BIT # TX-15

BIT # TX-20

BIT # TX-25

BIT # TX-30*

BIT # TX-45*

FLAT BLADE

SCREWDRIVER

1/4 inch or 6 mm

PHILLIPS SCREWDRIVER

PH1

PH2 and PH2 “Stubby"

PH3

NUT DRIVER 7 mm, 10 inches long

HEX WRENCH

3 mm

4 mm

5 mm

6 mm

8 mm

10 mm

OPEN END WRENCH

TORQUE WRE

5 mm

10 mm

13 mm

3/16 inch

Up to 81 Nm (59.7 lbf-ft)**

ADJUSTABLE WRENCH 152 mm (6 inches) long

PRY BAR approximately 18 inches overall (457 mm)

* 90 degree “L“ is suggested. A full set of 90 degree “L“ Torx wrenches are recommended.

** Heavy mechanical parts may need a specific torque. Each procedure will indicate the torque needed.

PPE Required During Service

• Safety Glasses

• Safety Shoes

• Cut Resistant Gloves

• Kneel pad (if kneeling is required)

• An ESD - mat and wrist strap

Loading...

Loading...