5. Adjusting the effective stroke

(on engines with end-of-delivery

adjustment):

– Prepare for the adjustment in the same

way as described for start-of-delivery

adjustment.

– Set the injection pump to the end of fuel

delivery.

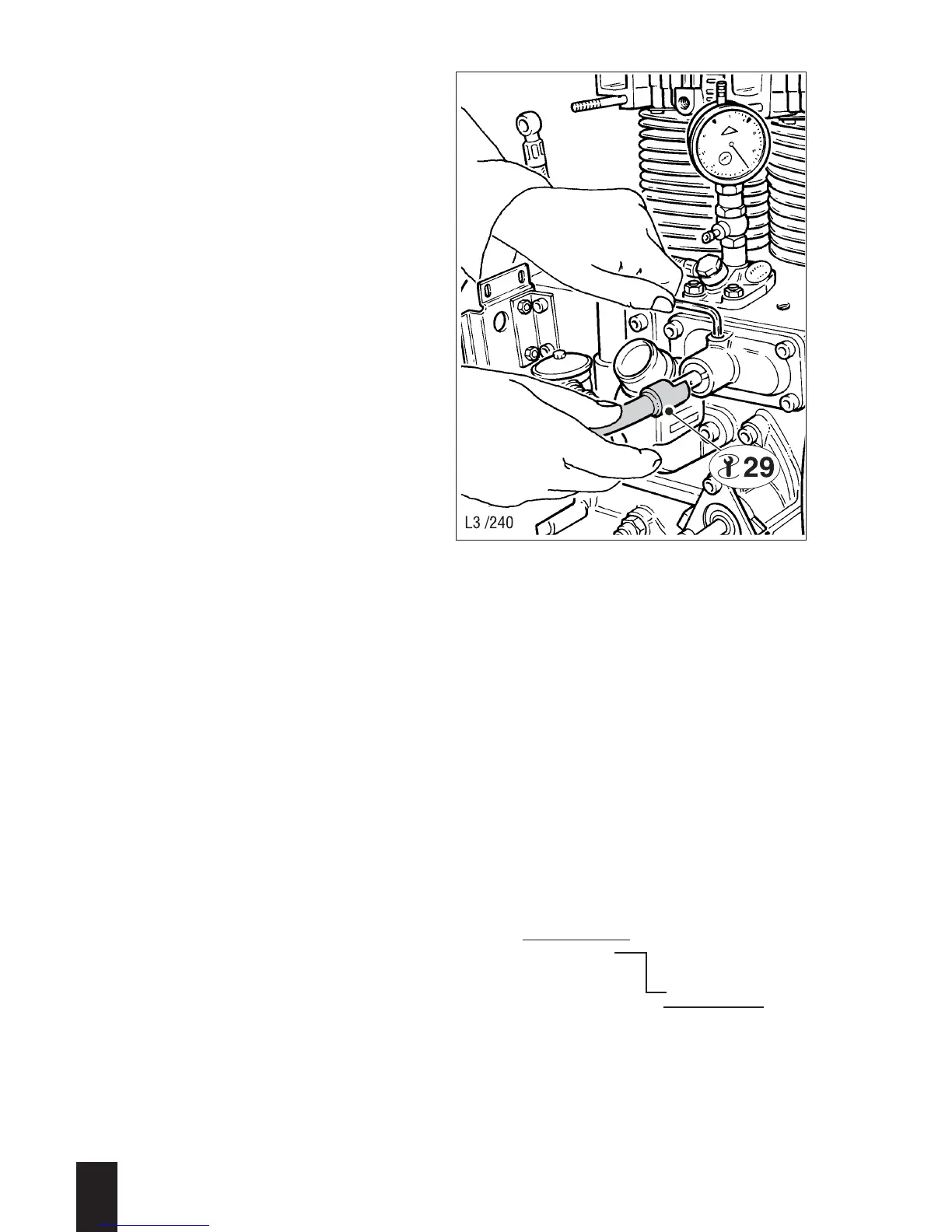

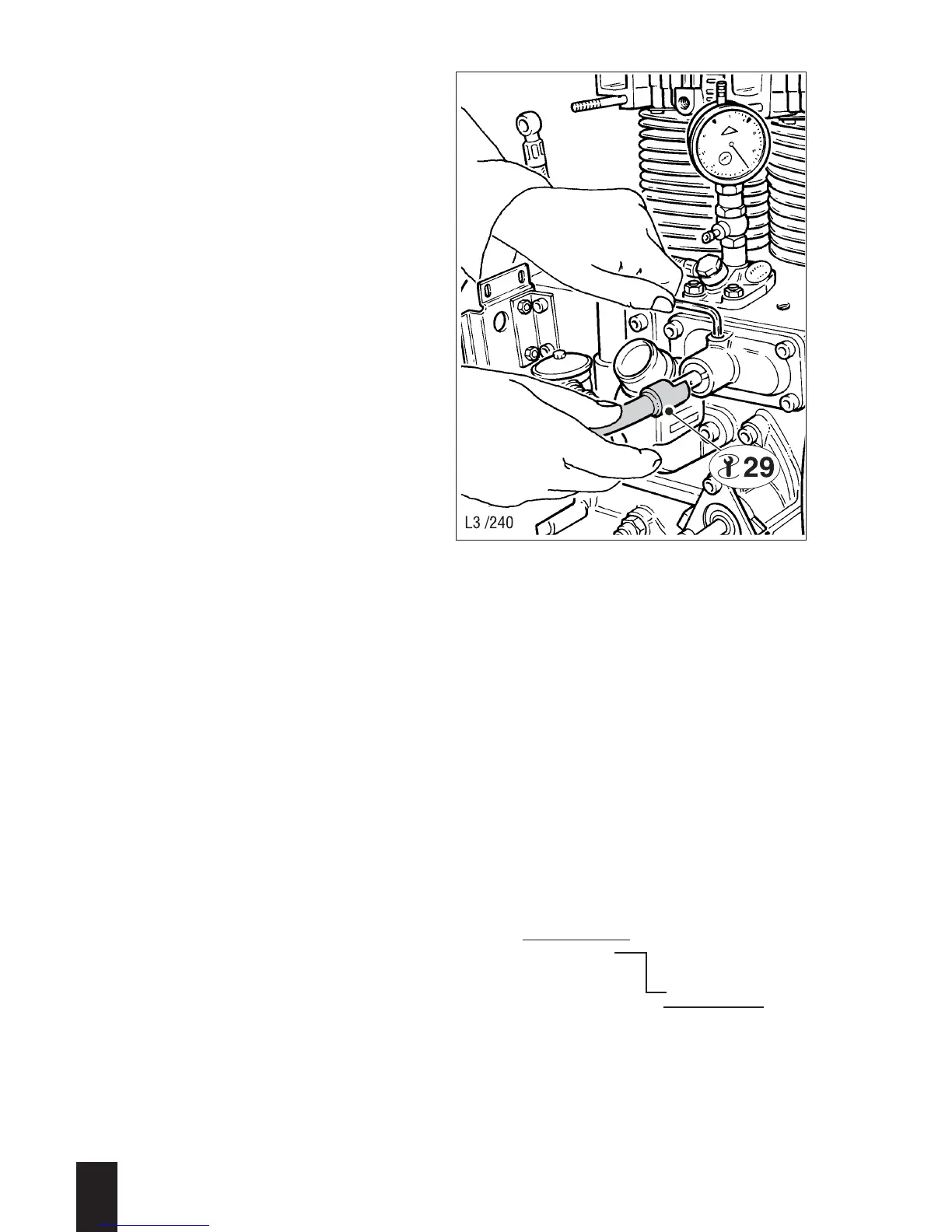

– Turn the crankshaft in the opposite

direction to normal rotation until the dial

gauge shows the nominal effective

stroke stated on the type plate.

– If necessary correct as described

above. For this use the starting

charge wrench - 29 - (see Fig. 137).

– After adjusting correctly tighten the grub

screw and seal it with lacquer.

– Remove the overflow device, install the

pressure valve with pressure tube con-

nection and tighten to the specified tor-

que.

3

L / M . . 09.96

137

6. Note on changing the power setting:

– Measure and make a note of the original power setting. Remember that as a result of

tolerances the actual effective stroke setting may not coincide exactly with the effecti-

ve stroke value on the type plate.

– The effective stroke setting for the desired power is obtained from the original effecti-

ve stroke setting plus (for an increase in power) or minus (for a decrease in power)

the difference between the two effective stroke values according to the adjustment

data.

Example:

To change an L 30 engine from power output B to power output F:

Effective stroke for power output F acc. table: 1,14 mm

– Effective stroke for power output B acc. table 1,07 mm

Difference between effective stroke values 0,07 mm

Effective stroke measured at engine: 1,05 mm

+ difference value 0,07 mm

New effective stroke setting 1,12 mm

Loading...

Loading...