- 13 -

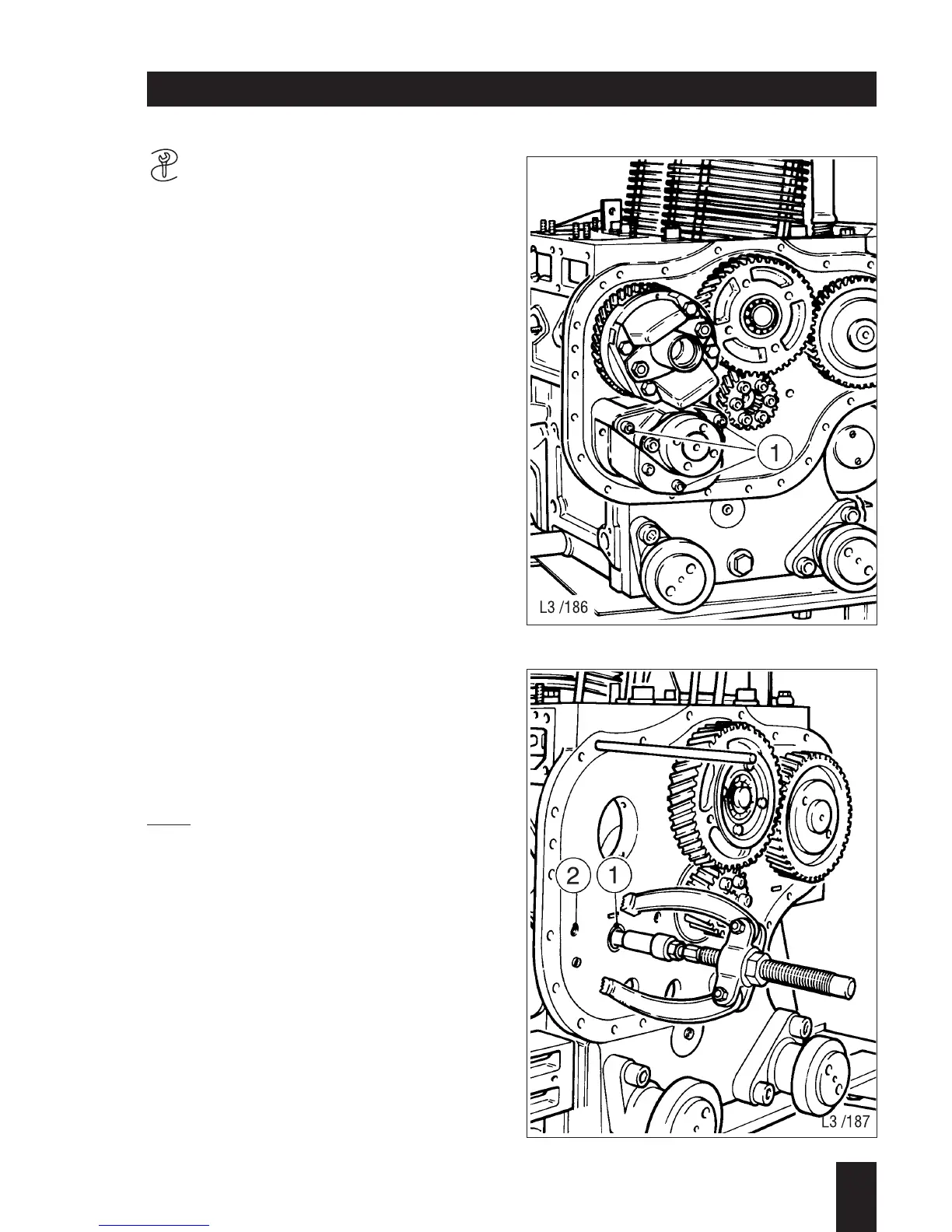

Preparations:

– Take off the timing case cover; see M

11.00.

Dismantling:

– Take out the machine screws (97/1) and

lift off the oil pump.

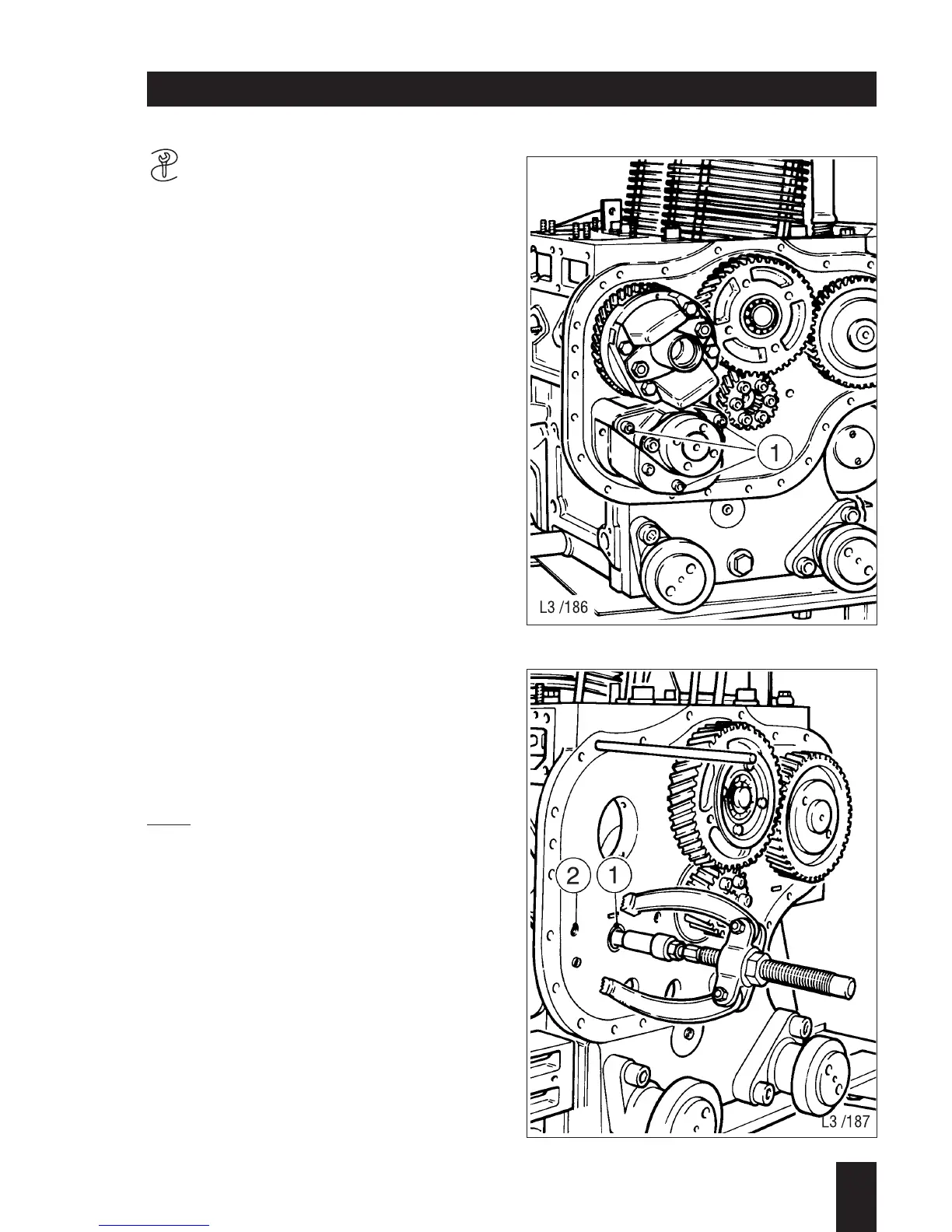

– If necessary, pull out needle roller bea-

ring (98/1) with an internal puller.

Checking / repairs:

– Examine the contact face for the shaft

sealing ring for score-marks.

If the contact face is worn, a „wear

sleeve“ can be pushed over it. Use sea-

lant E for this purpose.

Installation instructions are included with

the spare part.

Assembly:

– Using a plastic-faced hammer, drive the

needle roller bearing flush into the

crankcase.

– Insert the oil pump with bearing journal

into the needle roller bearing and place

it over the centering sleeves.

– Insert and tighten the machine screws.

Note:

– Apply sealant D to the machine screw

for hole (98/2).

– Coat the endface of the oil pump which

is in contact with the crankcase with

sealant B.

– Re-assemble the engine in the reverse

order for dismantling.

– When renewing the oil pump, make sure

that the correct type is installed (2- / 3-

or 4-cylinder engine).

3

L / M . . 09.96

97

98

M 10.00 Oil pump

Loading...

Loading...