50

SPM Flex Gas Detector

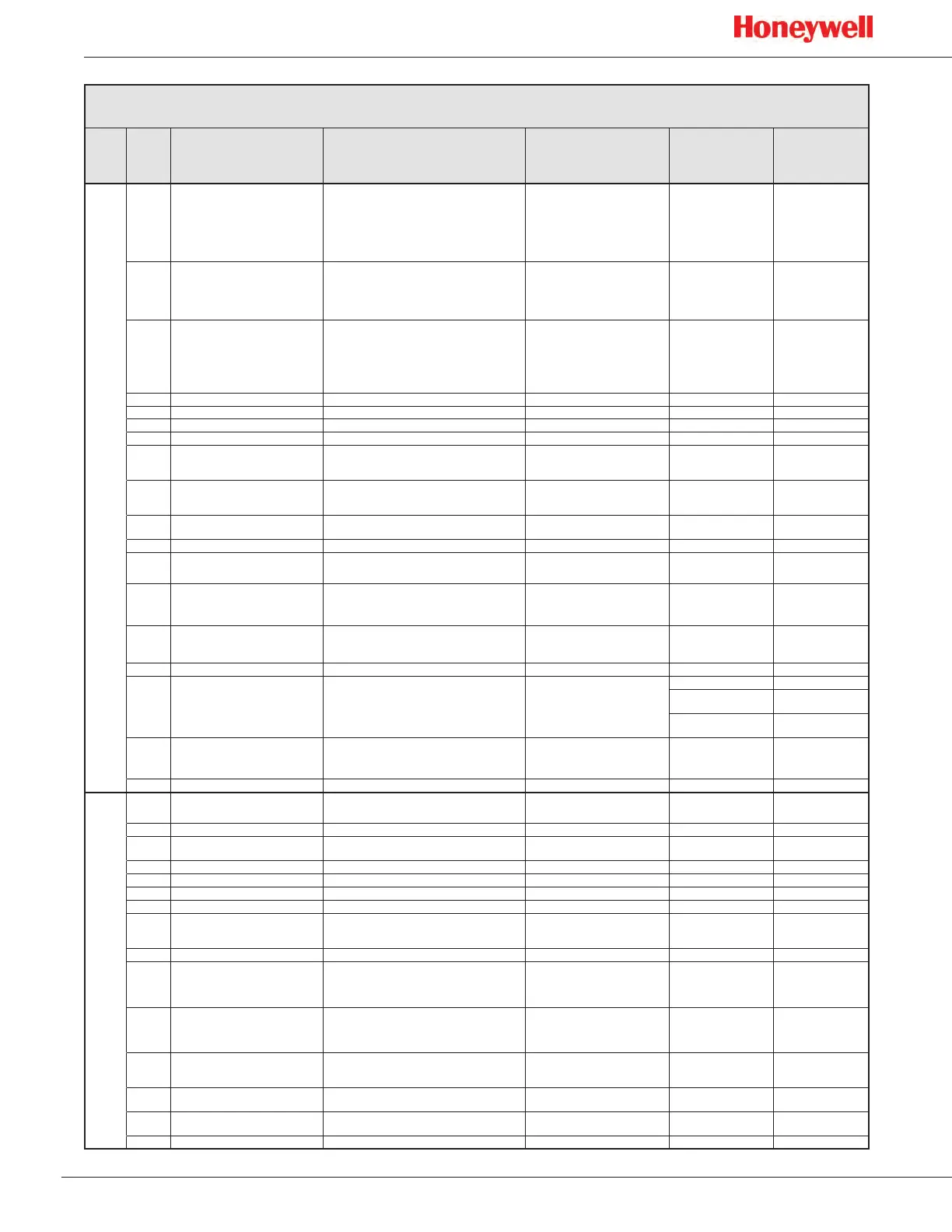

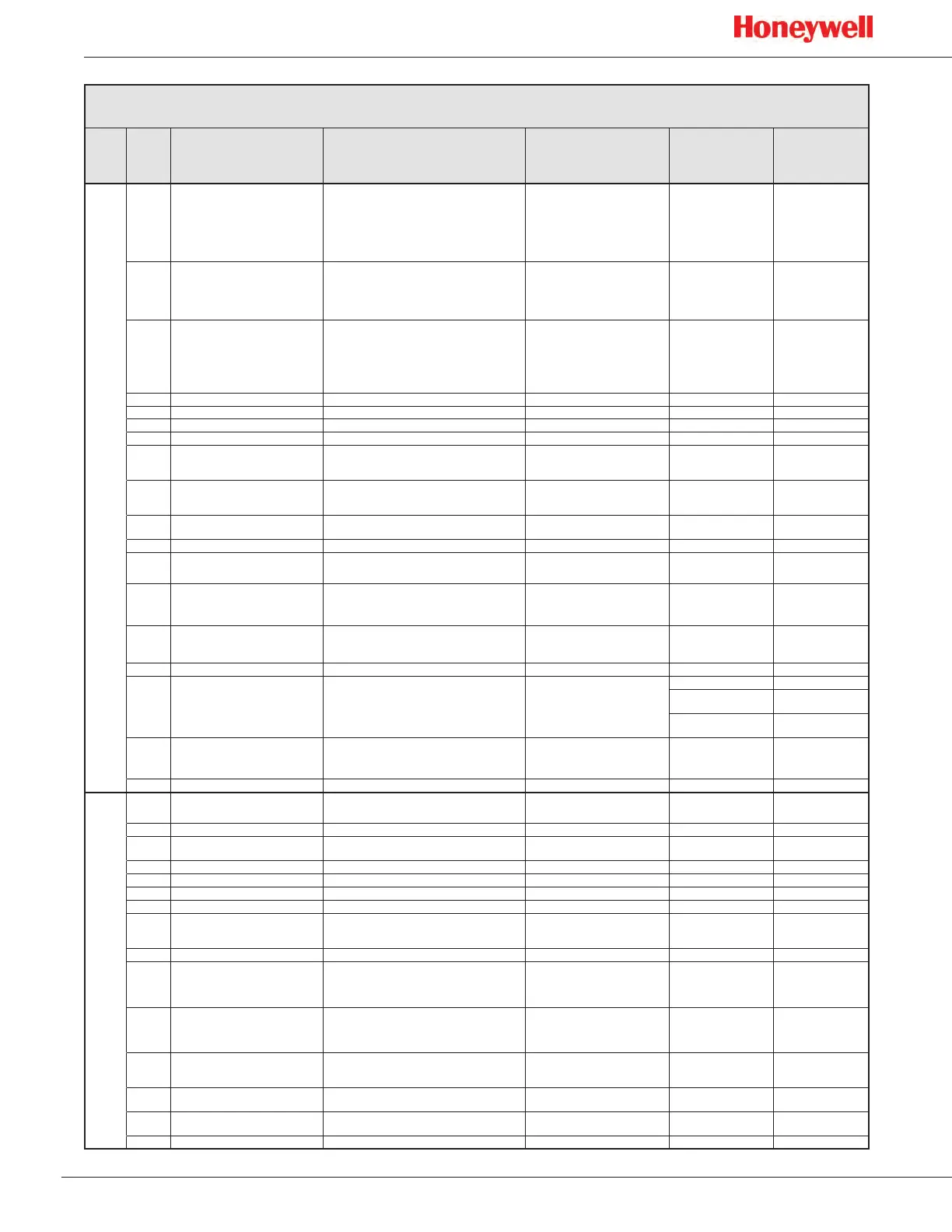

Instrument Fault/Maintenance Fault/Information Codes

Type

Sub-

type

Display

String

Technical

Description

Meaning of

Parameter

Probable

Cause

Corrective

Action

Instrument Faults

101 Flow Failure Flow failure Flow, cc/min

Pump failure

-Flow line obstruction

-Positive pressure

Replace pump

Check flow lines

Check for positive

pressure

103 Gate Motor Failure Gate timeout N/A

Gate motor failure

-Gate motor sensor

failure

Replace

104 Tape Advance Failure Tape advance timeout N/A

Broken tape

-Tape drive motor

failure

-Encoder failure

Replace

105 High Background optics counts too low after multiple pulls N/A Tape issue Check, replace

106 Gas Table Invalid Gas table invalid error code CC RFID issue Replace, contact HA

107 Comm� Failure RFID� comm� fail to RFID reader N/A RFID PCB failure Replace

108 Chemcassette Read Failure RFID read failure N/A CC RFID issue Replace, contact HA

109 Temperature Too High overtemperature Temperature, C

Environment is

over recommended

temperature

Improve ventilation/

cooling

110 Temperature Too Low undertemperature Temperature, C

Environment is

below recommended

temperature

Bring environment to

correct temperature

111 Optics Error

value of LED drive or reference detector signal

out of range

N/A Optics PCB failure Replace

112 Low Voltage Fault DC input voltage low voltage in Volts Faulty power circuit Contact HA

113 Chemcassette Expired

Now>LifeInBag+Mfg or

Now>LifeOutOfBag+FirstUse

1�0 or 2�0 for two causes

Chemcassette

cartridge has expired

Replace

114 Optics Subsystem Fail no comm� to optics block N/A

Optics cable

disconnected

-Optics PCB failure

Reconnect, replace

115 Comm� Failure GD no comm� to GD N/A Main PCB failure Contact HA

117 NV Memory Corrupt CRC error code to which test failed� PCB failure Replace

118 mA Output Mismatch Feedback ADC mismatches DAC Error magnitude in mA�

Faulty circuit Contact HA

Incorrect external

wiring

check wiring

Bad calibration

Perform mA

calibration

119 Ethernet Fail Ethernet hardware in UI failed to initialize N/A

External connection

issue

Main PCB failure

Check external

Ethernet connection

Replace

120 Battery Very Low Battery critically low, shutting down Battery level Low battery Charge detector

Maintenance Faults

1 Flow Warning Flow is unregulated Flow, cc/min

Flow out of control

range

Check Chemcassette

Check sample tube

2 Chemcassette Low Tape will run out in 24 hrs N/A Low tape Replace

3 Idle Timeout out of monitor too long N/A Out of monitor

Put in monitor and

reset fault

4 Low Voltage Warning DC input voltage low voltage in Volts

5 Comm Failure SPI no SPI comm� to UI N/A Contact HA

6 File System Error File system error in NAND or USB� N/A Contact HA

7 Comm� Invalid GD Invalid SPI parameter data from GD� N/A Contact HA

8 Warn CC Expiring

A stored tape will expire in 7 days; if enabled,

the same fault will be issued for cartridges

in use�

N/A Old tape Replace

9 Software Error catch all error code Contact HA

10 Optics Adjust Fail Calibration failure error code Calibration failure

Perform calibration

again, Check the

calibration setup,

Contact HA

11 Flow Cal Fail Calibration failure error code Calibration failure

Perform calibration

again, Check the

calibration setup,

Contact HA

12 Inhibit Timeout Timed out N/A

Detector has been left

in inhibit mode longer

than timeout warning

No action required

13 Force mA Timeout Timed out N/A

Detector has been in

force mode too long

No action required

14 Force Relay Timeout Timed out N/A

Detector has been in

force mode too long

No action required

15 Battery Low Battery Low Battery level Battery is low Charge battery

continued���

Loading...

Loading...