Do you have a question about the Honeywell TC Series and is the answer not in the manual?

| Category | Control Unit |

|---|---|

| Enclosure Rating | IP20 |

| Input Voltage | 24 VDC |

| Communication Protocol | Modbus RTU, BACnet MS/TP |

| Series | TC Series |

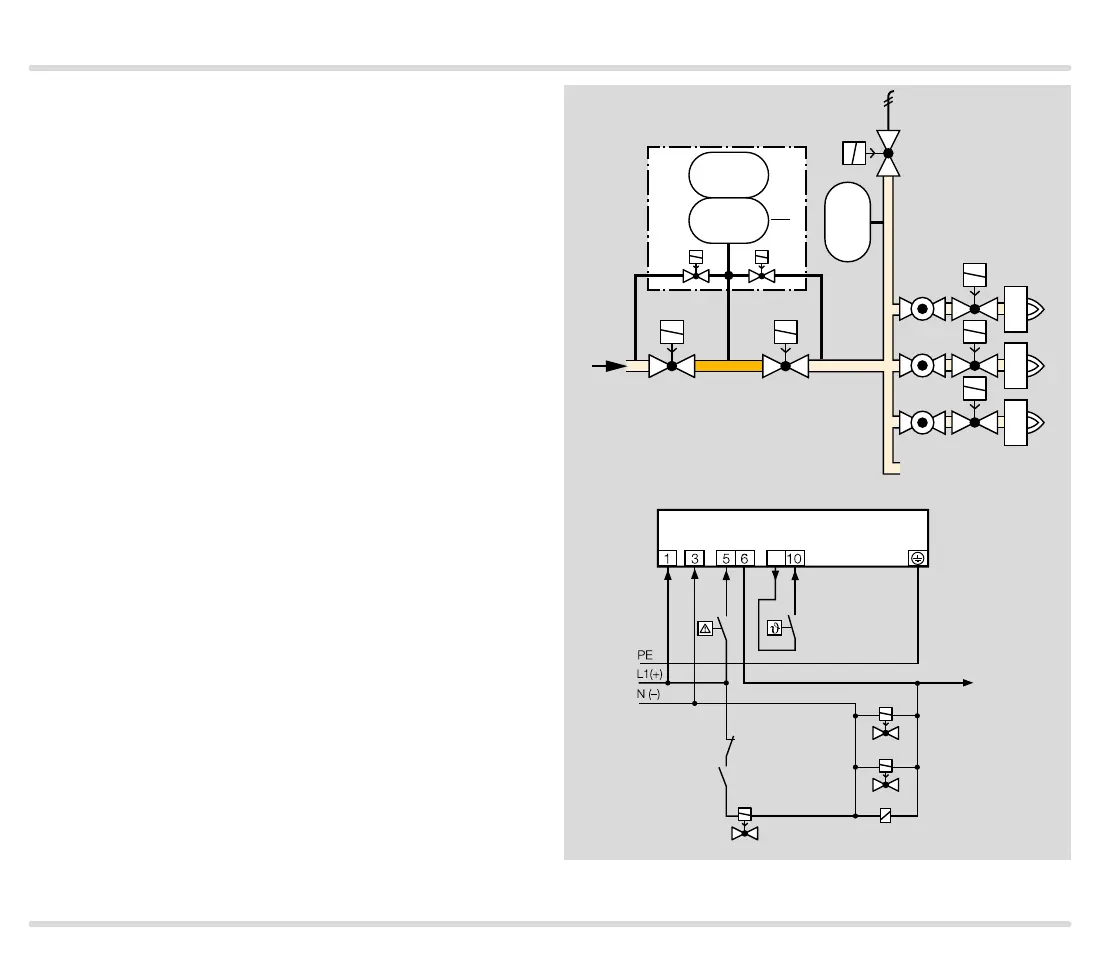

Details on application examples for TC 1V, TC 1C, TC 1, TC 2, TC 3, and TC 4 models.

Certifications for TC 1, TC 2, and TC 3 models, including SIL and PL.

Certifications for TC 4 model, including UL, FM, AGA, CE.

Functionality, connection diagrams, and test procedures for TC 1, TC 2, TC 3.

Functionality, connection diagrams, and test procedures for TC 4.

Selection tables and type codes for TC 1, TC 2, TC 3 models.

Selection tables and type codes for TC 4 model.

Guidelines for selecting auxiliary valves and minimum start rate for slow opening valves.

Instructions for installing TC units and their electrical connections.

Guidelines for determining the correct size for relief lines.

Details on standard sockets and valve connection cables.

Details on pressure switches DG, DG..C for TC 4 and their adjustment.

Electrical, environmental, and mechanical data for TC 1, TC 2, TC 3.

Electrical, mechanical, and environmental data for TC 4.

Operating controls, dimensions, and unit conversion information.

Safety characteristic values like SIL, PL, DC, PFHD for TC 1, TC 2, TC 3.

General safety, type of action, operating mode, and classifications for TC 1, TC 2, TC 3.

Electrical wiring, terminals, inputs, and outputs for TC 1, TC 2, TC 3.

Safety Integrity Level (SIL) and Performance Level (PL) for TC 1, TC 2, TC 3.

Definitions for terms like Tightness Control, VPS, Safety Interlocks, DC, PFHD, MTTFd.