OperatiOn

HPR130XD Auto Gas – 806330 Revision 2 4-21

Additional factors of cut quality

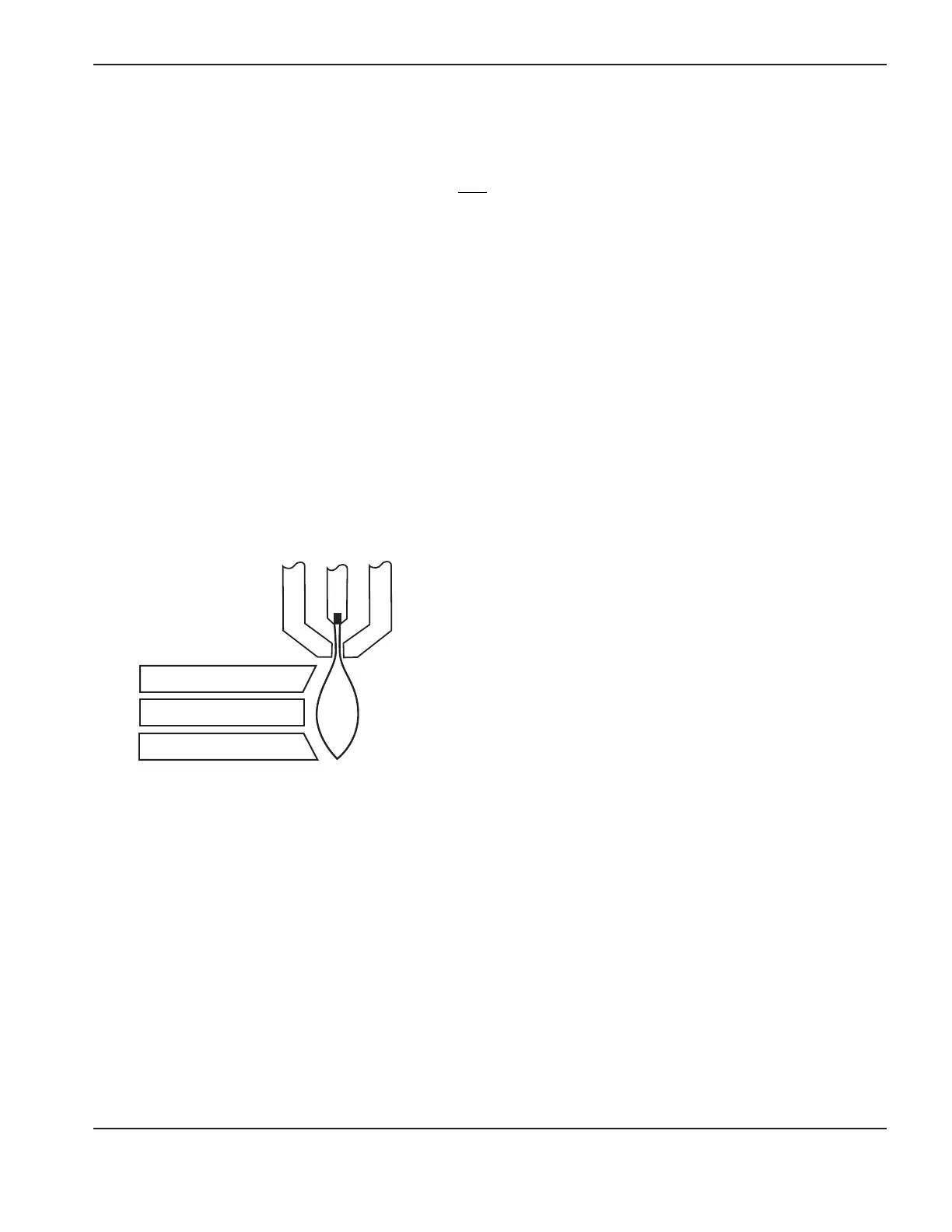

Cause

The torch is too low.

The torch is too high.

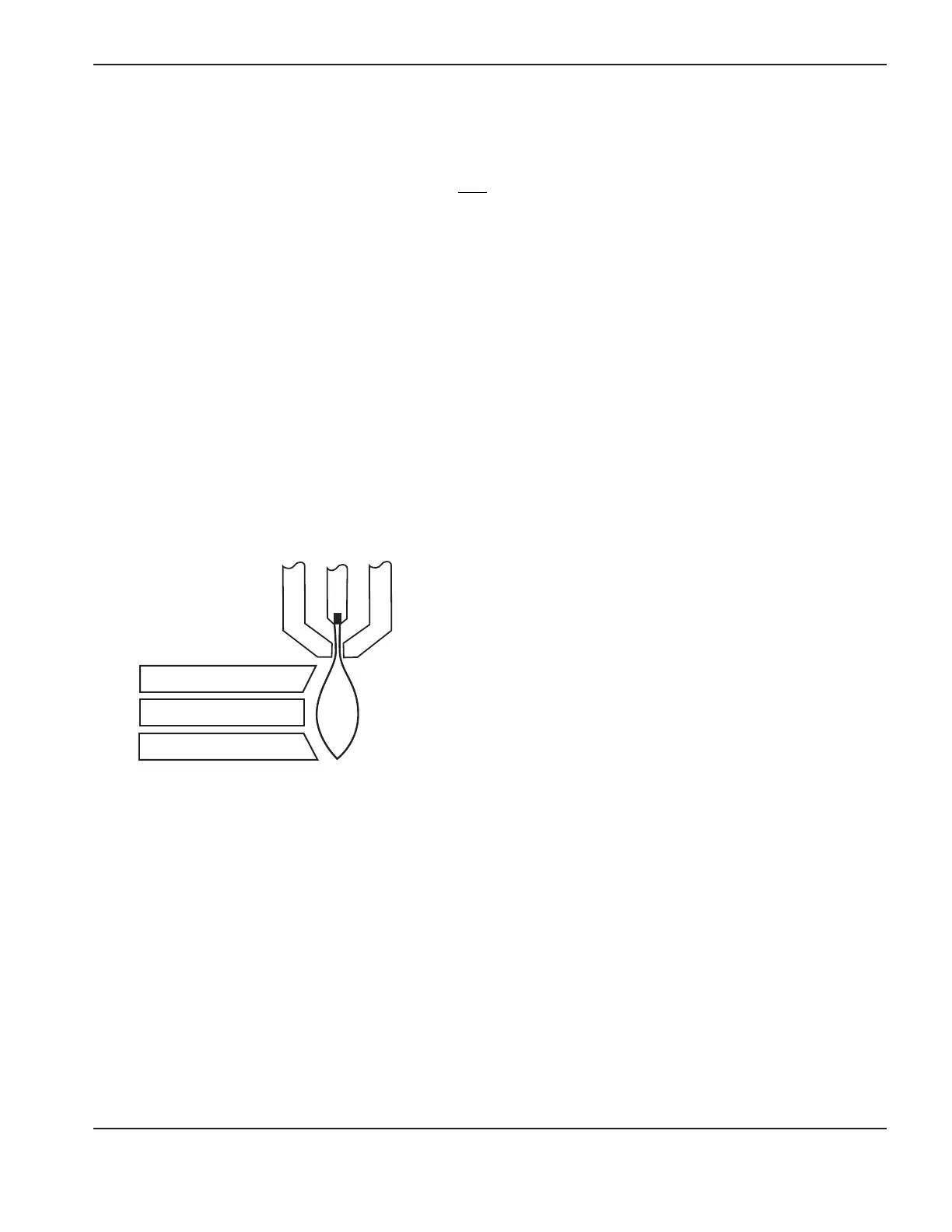

Square cut

\

Solution

Increase arc voltage to raise the torch.

Decrease arc voltage to lower the torch.

Positive cut angle

Negative cut angle

Problem

Additional factors of cut quality

Cut angle

Note: The squarest cut angle will be on the right side with respect to the forward motion of the torch.

Note: To determine whether a cut-angle problem is being caused by the plasma system or the drive

system, make a test cut and measure the angle of each side. Next, rotate the torch 90° in its

holder and repeat the process. If the angles are the same in both tests, the problem is in the

drive system.

If a cut-angle problem persists after “mechanical causes” have been eliminated (see

Tips for table and torch, previous

page), check the torch-to-work distance, especially if cut angles are all positive or all negative.

• Apositivecutangleresultswhenmorematerialisremovedfromthetopofthecutthanfromthebottom.

• Anegativecutangleresultswhenmorematerialisremovedfromthebottomofthecut.

Loading...

Loading...