InstallatIon

HPR130XD Auto Gas – 806330 3-49

Custom Coolant mix for hot operating temperatures

Water purity requirements

Custom Coolant mix for hot operating temperatures (above 38° C / 100° F)

Treated water (with no propylene glycol) can only be used as coolant when ambient temperatures are never

(32° F). For operations in very warm temperatures, treated water will provide the best cooling properties.

Treated water refers to a mixture of purifi ed water, that meets the specifi cations below, and 1 part benzotriazole (BZT)

to 300 parts of water. BZT (128020) acts as a corrosion inhibitor for the copper based coolant system contained in the

plasma system.

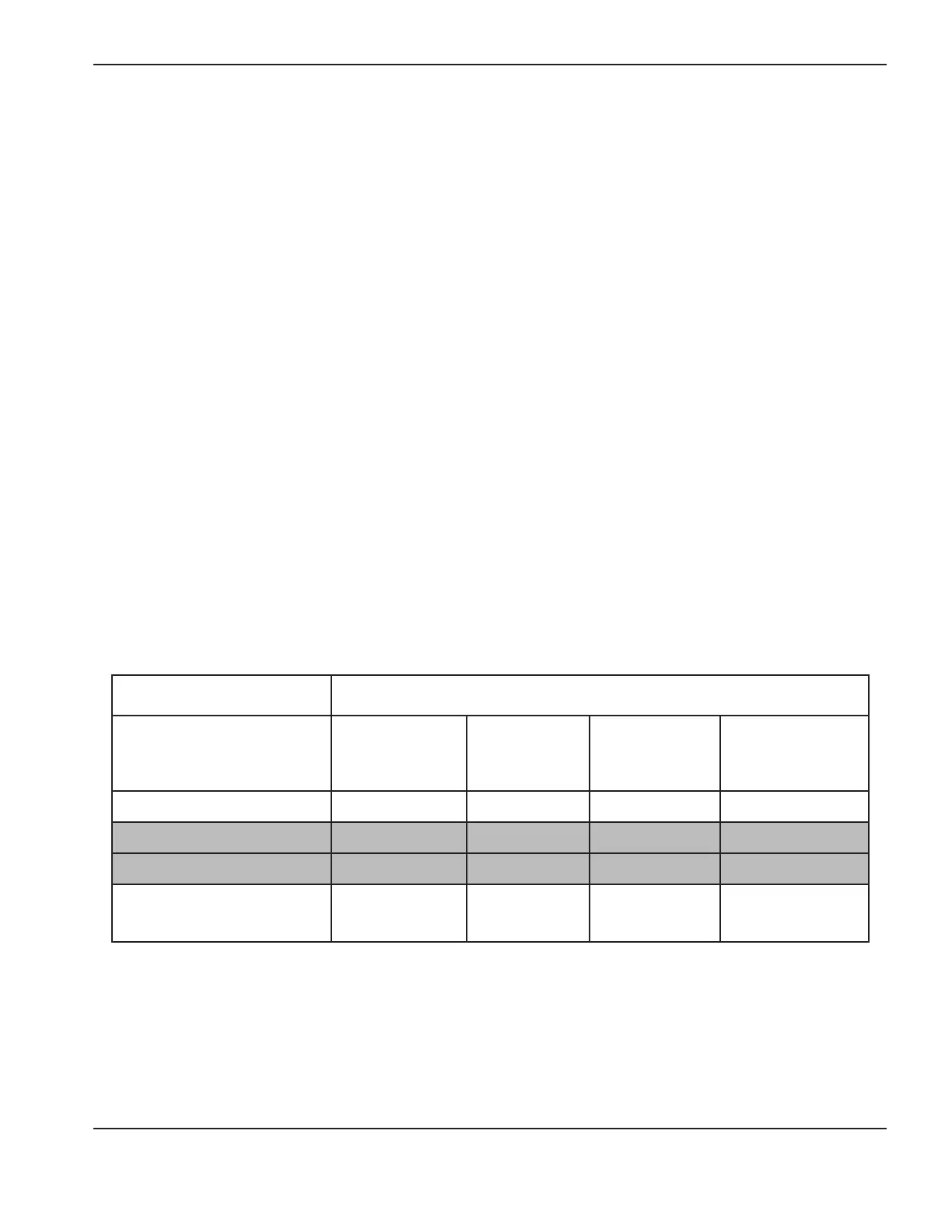

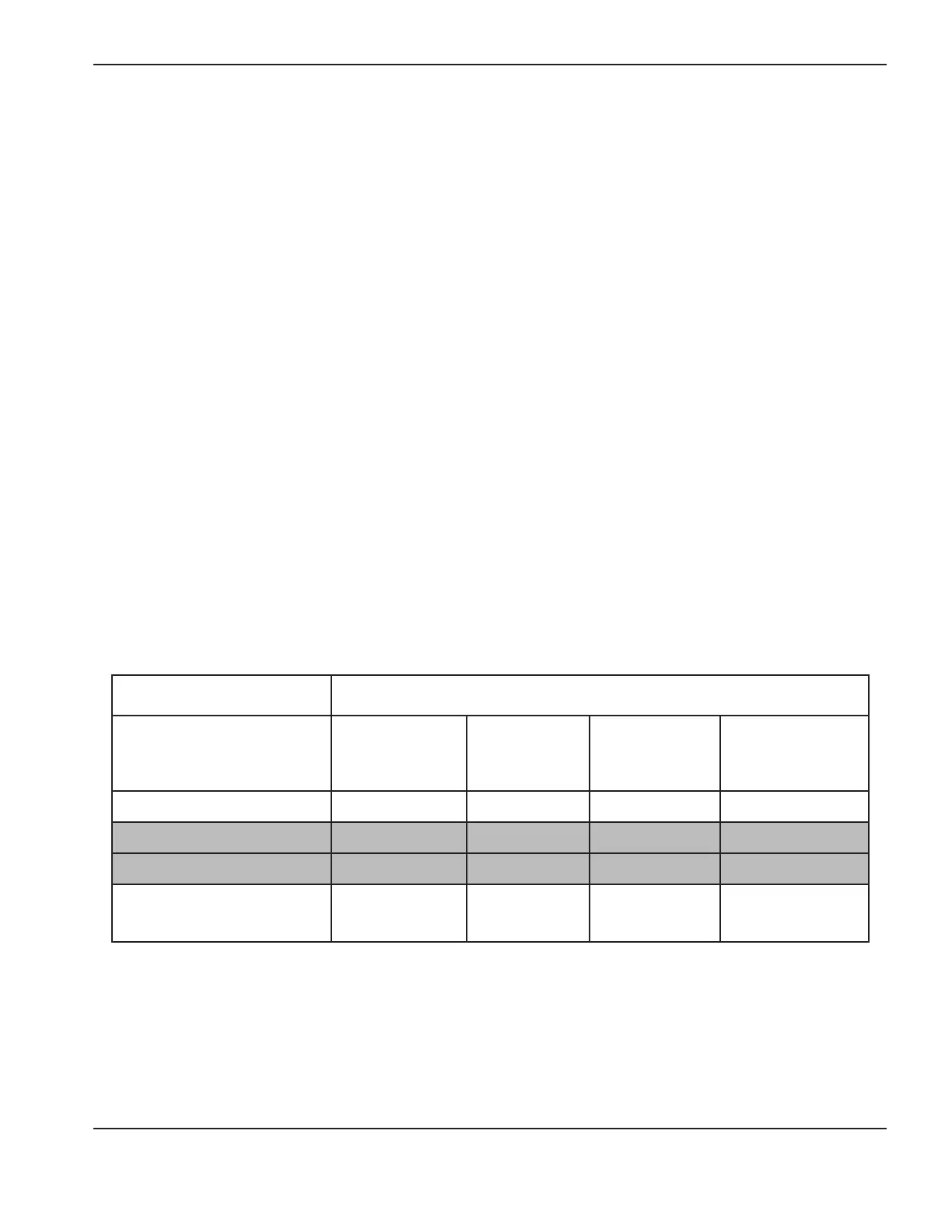

Water purity requirements

It is critical to maintain a low level of calcium carbonate in the coolant to avoid reduced performance of the torch or

cooling system.

Always use water that meets the minimum and maximum specifications in the table below when using a custom coolant

mix.

Water that does not meet the minimum purity specifications below can cause excessive deposits on the nozzle that will

alter the water flow and produce an unstable arc.

Water that does not meet the maximum purity specifications below can also cause problems. Deionized water that is too

pure will cause leaching problems with the coolant system plumbing.

Use water purified by any method (deionization, reverse osmosis, sand filters, water softeners, etc.) as long as the water

purity meets the specifications in the table below. Contact a water specialist for advice in choosing a water filtration

system.

Water purity measurement method

Water purity

Conductivity

μS/cm

at25°C(77° F)

Resistivity

mΩ-cm

at25°C(77° F)

Dissolved solids

(ppm of NaCl)

Grains per gallon

(gpg of CaCO

2

)

Pure water (for reference only) 0.055 18.3 0 0

Maximum purity 0.5 2 0.206 0.010

Minimum purity 18 0.054 8.5 0.43

Maximum potable water

(forreference only)

1000 0.001 495 25

10/16/08

Loading...

Loading...