Maintenance

5-40 HPR130XD Auto Gas – 806330

Test 3 – change the torch

1. Replace the torch and consumables with a new torch and new consumables.

2. Turn ON the pump manually using the manual pump control button on your CNC screen (see step 1 under “Manual

pump operation”), let it run for 60 seconds, and look at the flow rate on the CNC screen.

If the flow rate on the CNC screen is 0.9 gpm or more, replace the torch.

If the flow rate is still less than 0.9 gpm, go to test 4.

Test 4 – supply line to the torch receptacle

1. Turn OFF the power. Remove the coolant supply line from the torch receptacle, and place it in a 3.8 liter (1 gallon)

container. A Hypertherm coolant container works well.

2. Measure how long it takes to fill the container. Turn ON the power. Turn ON the pump manually using the manual

pump control button on your CNC screen (see step 1 under “Manual pump operation”). Write down how long it

takes to fill the container.

3. Reconnect the coolant supply line to the torch receptacle.

If it takes more than 65 seconds to fill the container, look for an obstruction or kink in the coolant hose between the

torch and the LHF/RHF console. If there is no obstruction or kink, replace the torch leads.

If the container is full in 65 seconds or less, go to test 5.

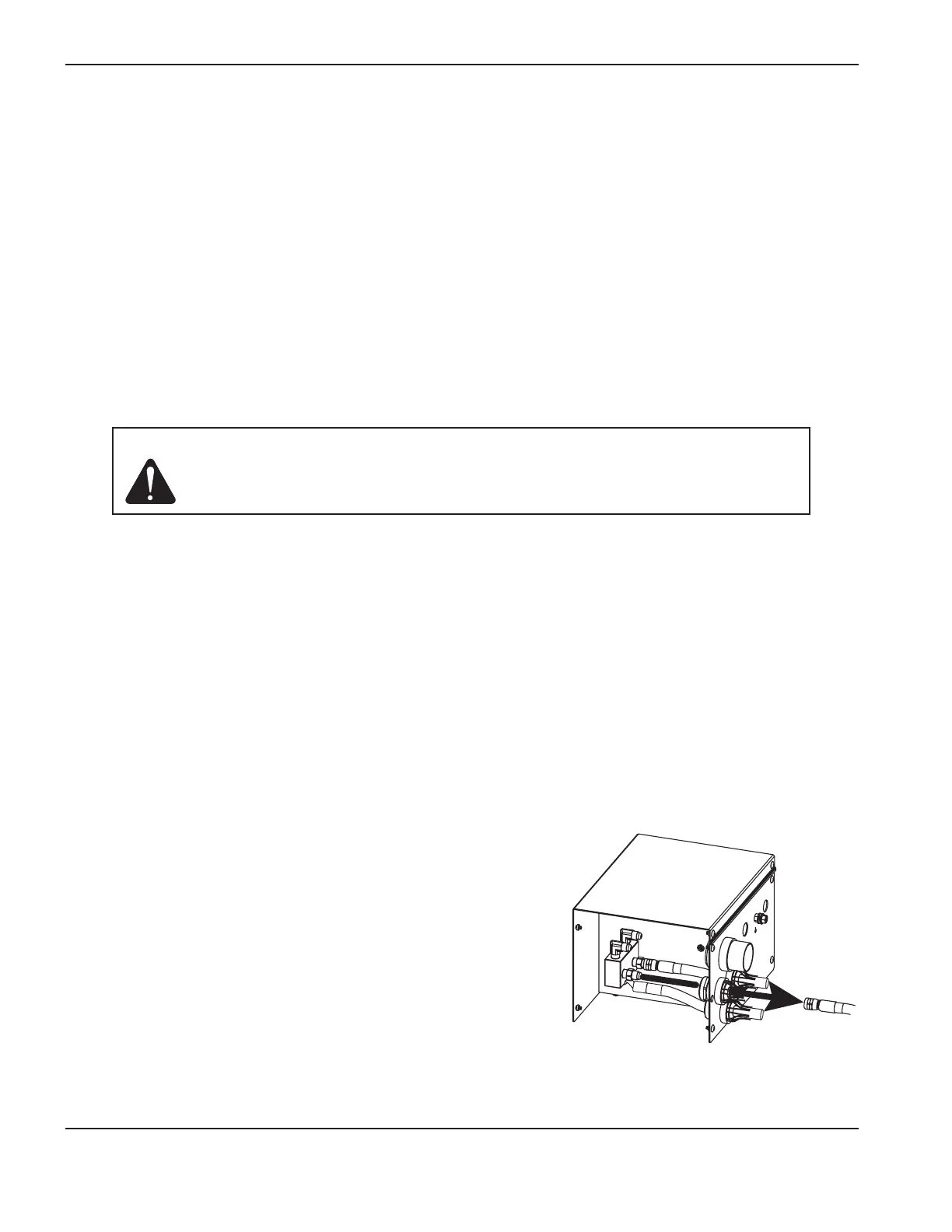

Test 5 – return line from the torch receptacle (remove at the ignition console)

1. Turn OFF the power. Remove the return coolant line (blue hose

with red tape) from the RHF/LHF console, and place it in a 3.8 liter

(1gallon) container. A Hypertherm coolant container works well.

2. Measure how long it takes to fill the container. Turn ON the power.

Turn ON the pump manually using the manual pump control button

on your CNC screen (see step 1 under “Manual pump operation”).

Write down how long it takes to fill the container.

3. Reconnect the return coolant line.

If it takes more than 65 seconds to fill the container, there is an

obstruction in the torch receptacle. replace the torch receptacle.

If the container is full in 65 seconds or less, there is an obstruction in

thereturn coolant line (from the RHF/LHF console to the power supply).

Replace the return coolant line.

Caution: Coolant will flow from the hose very quickly.

Loading...

Loading...