Maintenance

HPR130XD Auto Gas – 806330 5-11

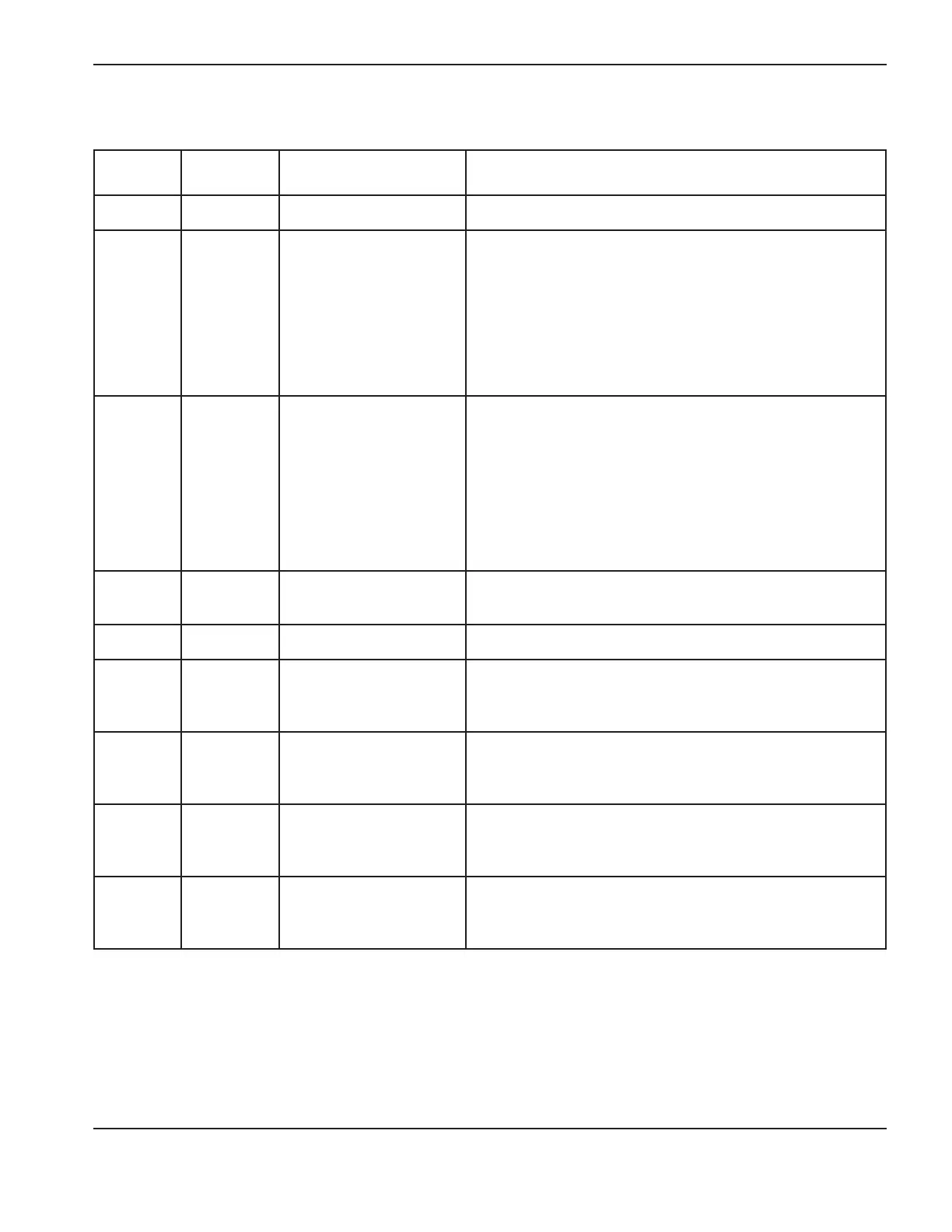

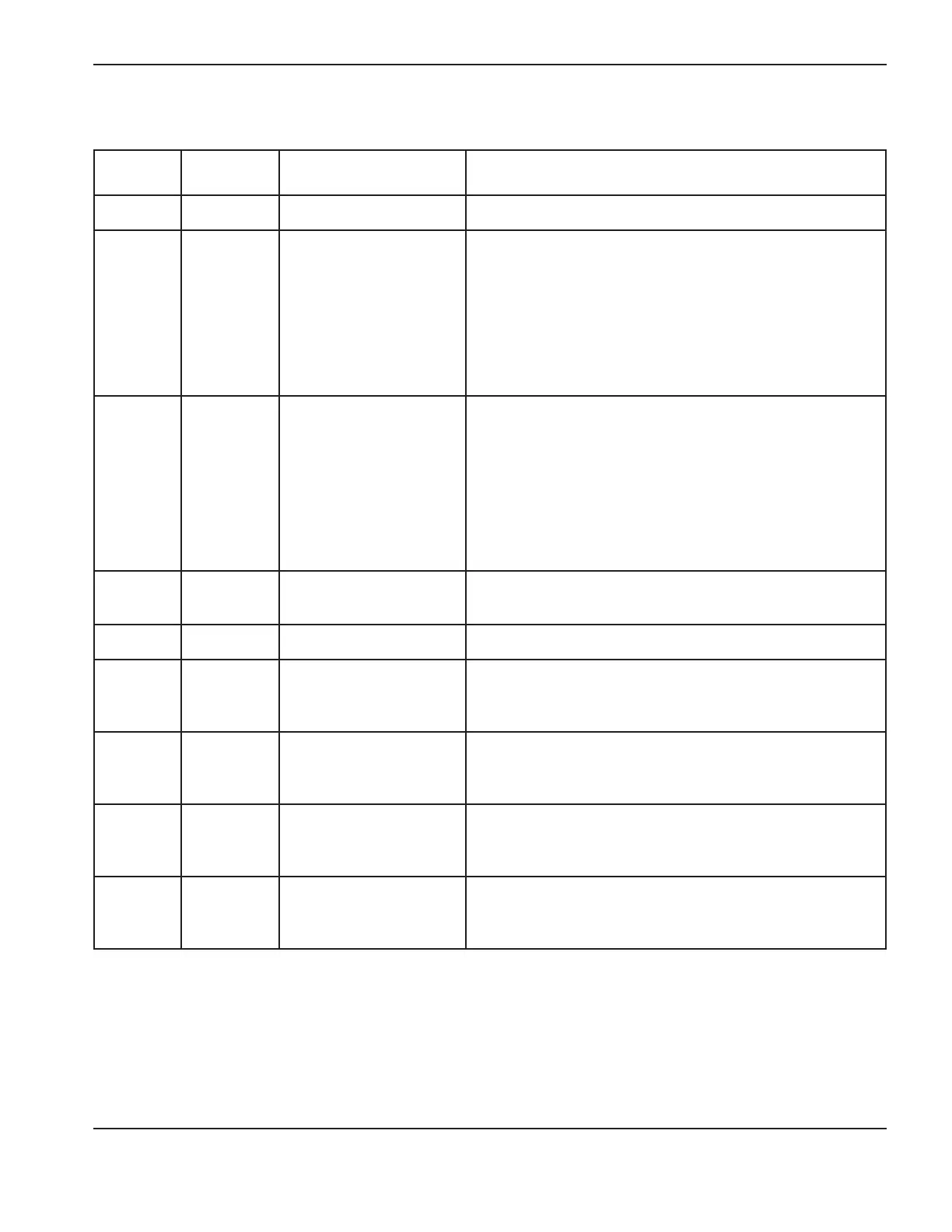

Error code troubleshooting – error codes 000 to 018

Error code

number

Name Description Corrective action

000 No error System is ready to run. None needed.

009

Flow switch

test

The flow switch is tested

when the pump restarts

after a pump timeout

(30minutes without a

start signal). The test

ensures that the coolant

flow is correct before

firing the torch.

Wait 10 seconds for the flow rate to stabilize.

011

No active

processs

HPR400XD

HPR800XD

Only

The current setting is

greater than the capability

of the selected process.

When this error code

occurs, the power supply

will ignore the start signal

until a correct process

ischosen.

Note: To protect against unintended operation after a

system reset, the current will be set to 5 amperes.

If a correct proces is sent, the system will operate

normally.

1. Verify that the secondary power supply is turned ON.

2. Verify that the current for the selected process is within

the range of the power supply capability (up to 400A for

400XD, and up to 800A for 800XD).

012

Test in

progress

One of the gas test

modes is running.

Wait for the test to finish.

013 Test passed The test was successful. No action required.

014

Cut gas

channel 1 fail

The gas pressure in

channel 1 is decreasing,

which indicates a leak.

Look for leaks and loose connections between the selection

console and the metering console.

015

Cut gas

channel 2 fail

The gas pressure in

channel 2 is decreasing,

which indicates a leak.

Look for leaks and loose connections between the selection

console and the metering console.

016

Plasma

rampdown

fail

Plasma pressure did

not decrease in the time

allowed.

Verify that there is no obstruction in the plasma vent hose.

017

Shield

rampdown

fail

Shield pressure did not

decrease in the time

allowed.

Inspect the holes in the shield for obstructions. Replace the

shield if the holes are blocked.

Loading...

Loading...