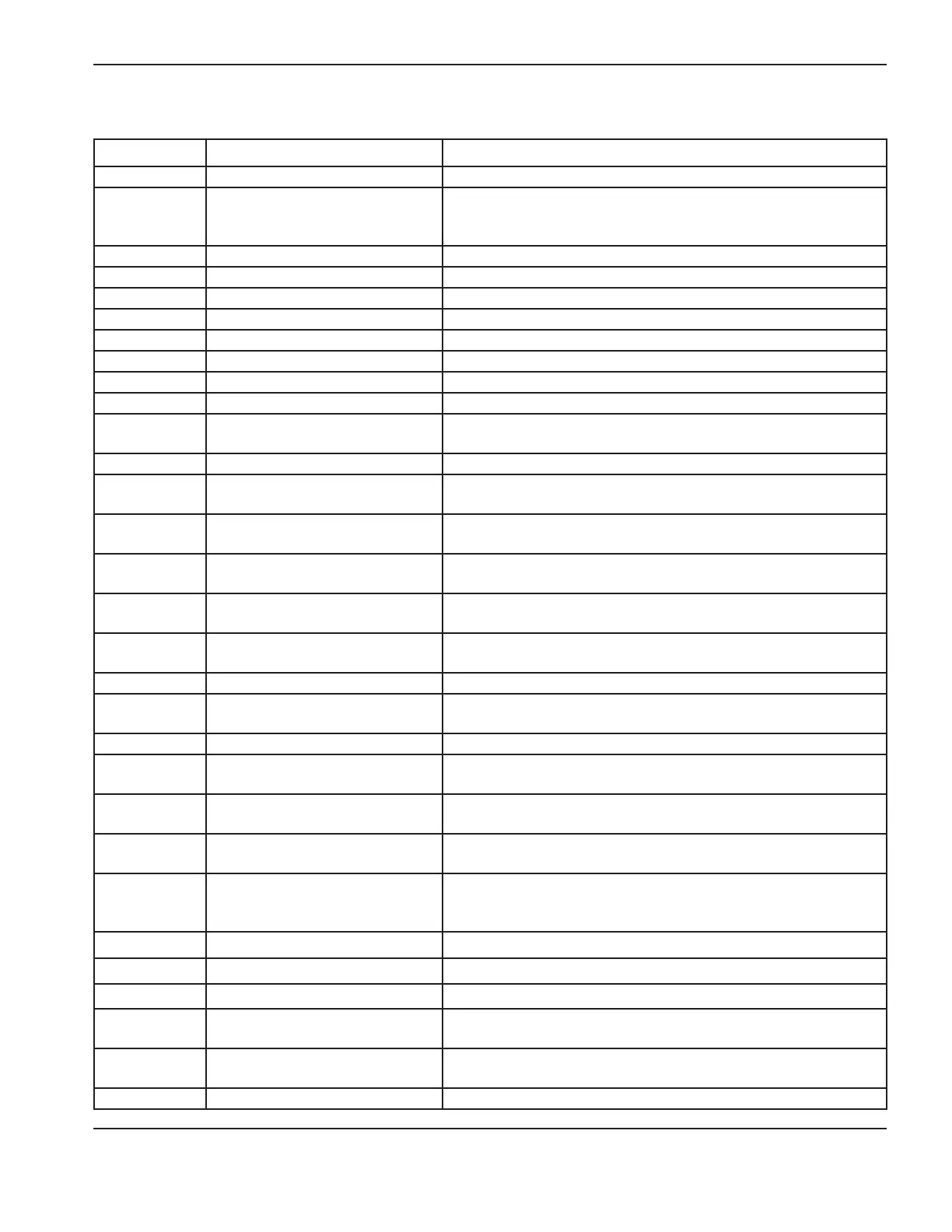

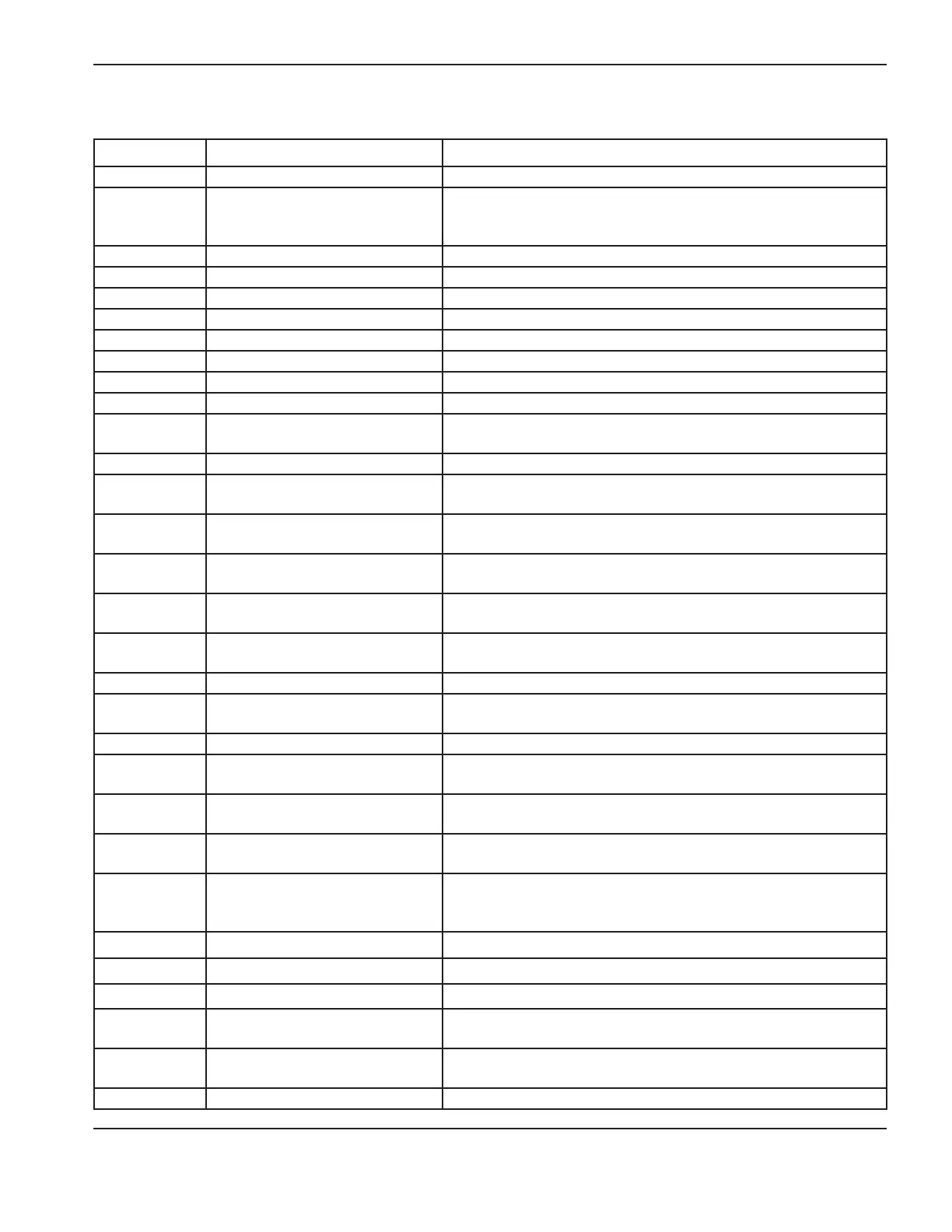

Appendix B – CnC interfACe protoCol

HPR130XD Auto Gas – 806330 Revision 1 b-21

Error codes

ID Name Description

000 NO ERROR System is ready to run.

009 FLOW SWITCH TEST

When the pump is restarted after a pump timeout (30 minutes

without a start signal) the system will test the flow switch to make

sure there is sufficient flow before firing the torch.

011 NO_ACTIVE_PROCESS The power supply receives an invalid current setting from a CNC.

012 TEST IN PROGRESS One of the gas test modes is running.

013 TEST PASSED The test completed successfully.

014 CUT GAS CHANNEL #1 FAIL The gas pressure is dropping on channel #1, indicating a leak.

015 CUT GAS CHANNEL #2 FAIL The gas pressure is dropping on channel #2, indicating a leak.

016 PLASMA RAMP-DOWN FAIL Pump output has exceeded 200 psi.

017 SHIELD RAMP-DOWN FAIL Shield pressure did not decrease in the allotted time.

018 PUMP OVER PRESSURE Pump output has exceeded 13.79 bar (200 psi.)

020 NO PILOT ARC

No current detected from chopper at ignition and before

1-second timeout.

021 NO ARC TRANSFER No transfer signal detected before 500-msec timeout.

024 Primary

224 Secondary

LOST CURRENT CH1 After transfer, lost the chopper current signal.

025 Primary

225 Secondary

LOST CURRENT CH2 After transfer, lost the chopper current signal.

026 Primary

226 Secondary

LOST TRANSFER After transfer, lost the transfer signal.

027 Primary

227 Secondary

LOST PHASE When main contactor is engaged, no “phase OK” input.

028 Primary

228 Secondary

LOST CURRENT CH3 After transfer, lost the chopper current signal.

030 GAS SYSTEM ERROR A failure has occurred in the gas system.

031 Primary

231 Secondary

START LOST Start signal was removed before steady-state operation.

032 HOLD TIMEOUT Hold signal was applied for longer than 60 seconds.

033 PRE CHARGE TIMEOUT

Gas console was not able to charge the gas lines to the correct

pressure.

034 Primary

234 Secondary

PRE CHARGE TIMEOUT

Gas console was not able to charge the gas lines to the correct

pressure.

042 LOW NITROGEN PRESSURE

Nitrogen gas pressure under lower limit of 2.07 bar (30 psi) –

cutting, 0.34 bar (5 psi) – marking

044 LOW PLASMA GAS PRESSURE

Gas pressure under lower limit of 0.34 bar (5 psi) – pre-flow

3.45 bar (50 psi) – cutflow (cutting) 0.34 bar (5 psi) – cutflow

(marking).

045 HIGH PLASMA GAS PRESSURE Gas pressure over upper limit of 7.58 bar (110 psi).

046 LOW LINE VOLTAGE Line voltage is under lower limit of 102 VAC (120 VAC -15%).

047 HIGH LINE VOLTAGE Line voltage is over upper limit of 138 VAC (120 VAC +15%).

048 Primary

248 Secondary

CAN ERROR An error occurred with the CAN communication system.

050 Primary

250 Secondary

START ON AT INIT Start signal input is active during power-up.

053 LOW SHIELD GAS PRESSURE Gas pressure is under lower limit of 0.14 bar (2 psi).

Loading...

Loading...