OPERATION

HySpeed HT2000LHF Instruction Manual 4-29

Shield Arc Approx.

Material

Plasma Gas Flow Rate %

Gas (Air) Torch-to-work Initial Torch Voltage Motion

Thickness Preflow Cutflow Pressure Distance Piercing Height Setting Travel Speed Delay Time

(inches) (mm) (O

2

%N

2

%) (O

2

%N

2

%) (psi) (inches) (mm) (inches) (mm) (volts) (ipm) (mm/min.) (sec)

1/4 6 12 38 64 0 60 1/8 3 1/4 6 115 160 4060 0.5

.315 8 (14.9 / 50.4 (79.6 / 0 (270 1/8 3 1/4 6 120 120 3000 0.5

3/8 10 SCFH) SCFH) SCFH) 1/8 3 1/4 6 120 100 2540 1.0

1/2 12 .157 4 .314 8 120 80 2030 2.0

5/8 15 .157 4 .314 8 125 70 1780 2.0

3/4 20 3/16 5 3/8 10 130 55 1400 2.5

7/8 22 1/4 6 1/2 12 135 45 1140 2.5

1 25 1/4 6 1/2 12 135 35 890 2.5

1 1/4 32 1/4 6 140 22 560

1-1/2 38 1/4 6 150 15 380

1-3/4 44 5/16 8 160 10 250

2 50 5/16 8 170 7 180

Mild Steel - Beveling Consumables

200 amps • O

2

Plasma / Air Shield

Notes: Set oxygen plasma gas inlet pressure to 120 psi (8.3 bar).

Set nitrogen plasma gas inlet pressure to 120 psi (8.3 bar).

Set shield gas inlet pressure to 90 psi (6.2 bar).

Production cutting above 1" (25 mm) not recommended

Beveling cuts should be made between 45° and 90° to the work surface.

Above Water Only

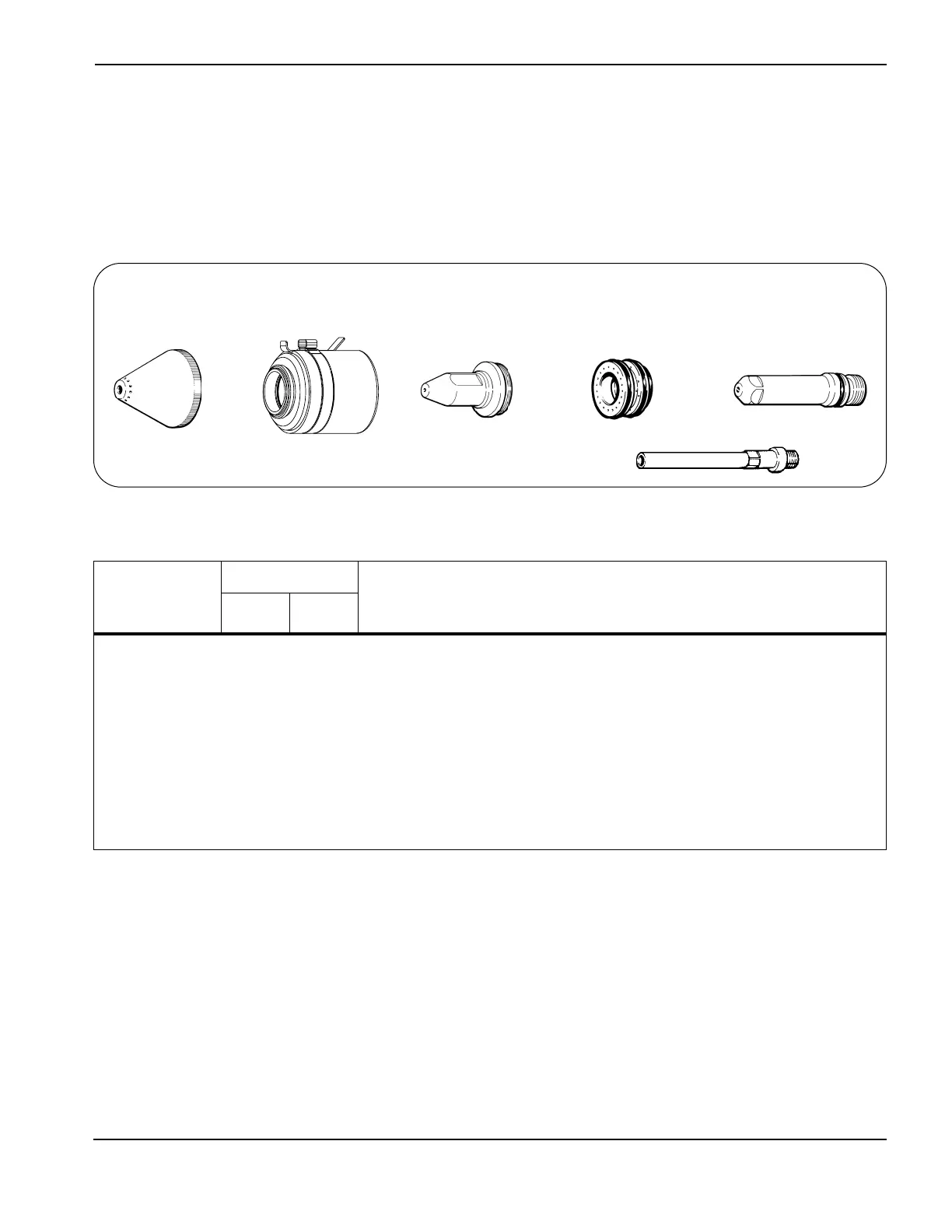

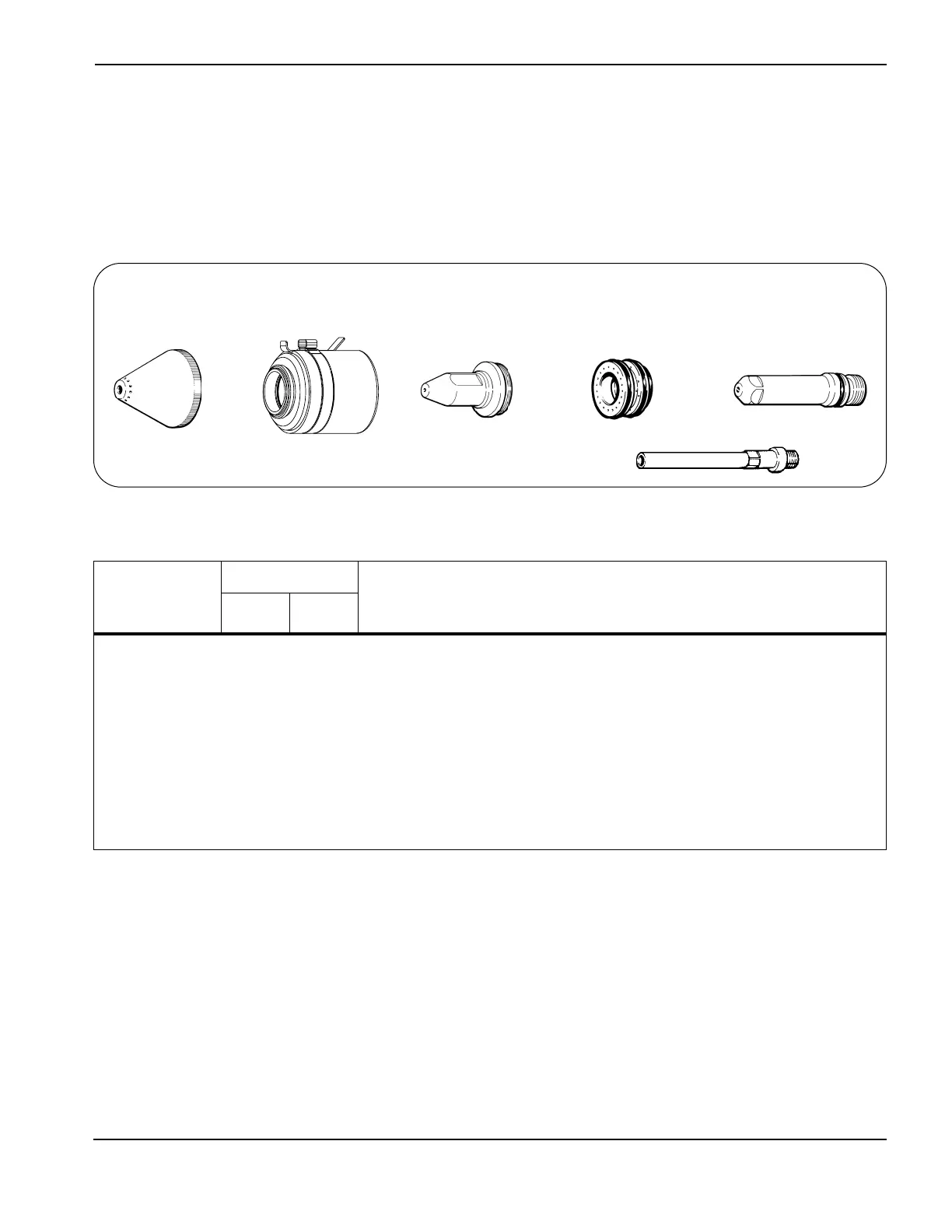

120833 (cw)

120834 (ccw)

Swirl ring

120258

Electrode

120257

Water Tube

120259

Nozzle

120837

(cw)

120838 (ccw)

Retaining cap

120260

Shield

7

Loading...

Loading...