POWER SUPPLY SETUP

2-8 powermax

45

Operator Manual

Gas supply

Powermax45

Water and particle filter

Oil filter Oil vapor filter

Additional gas filtration

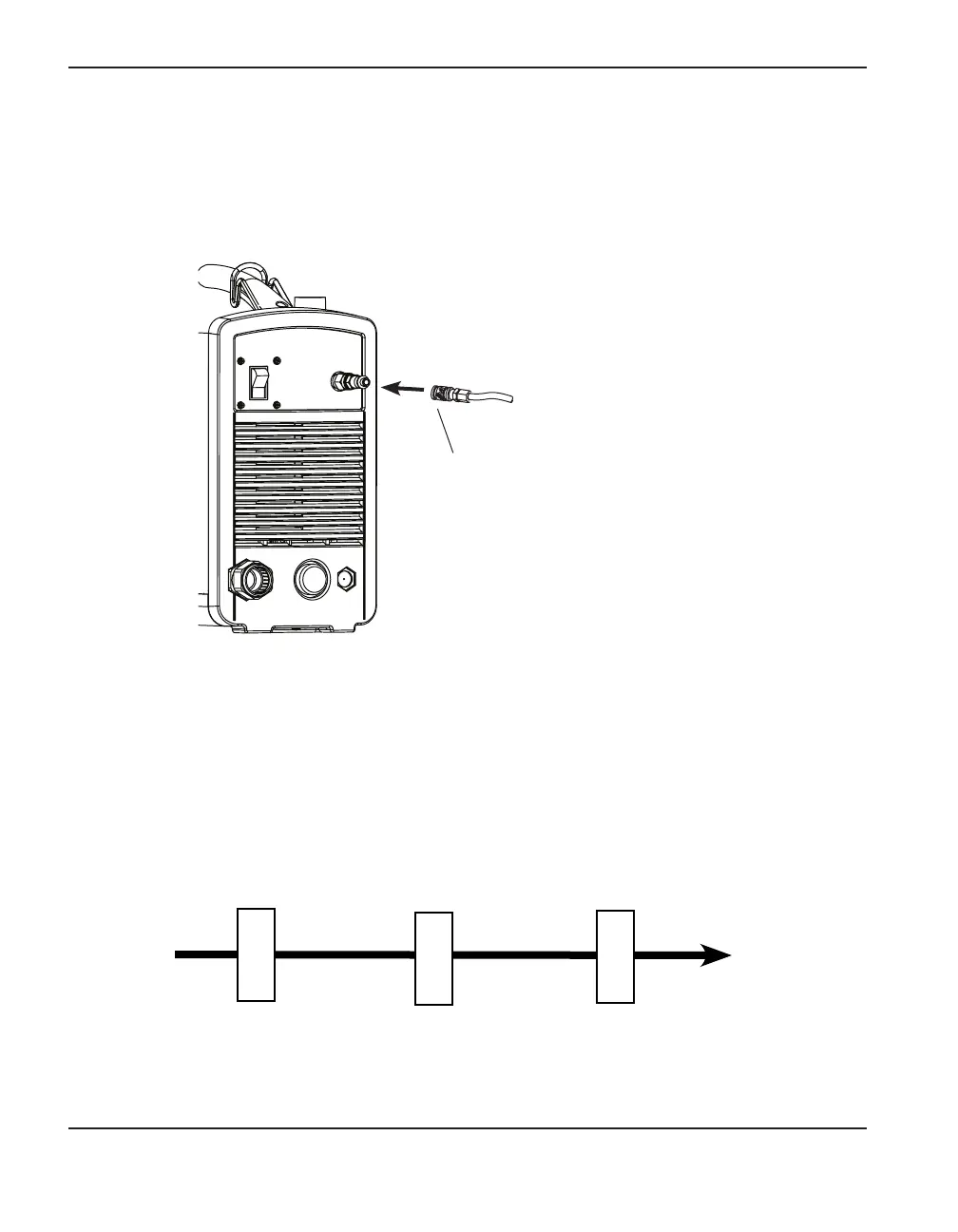

When site conditions introduce moisture, oil, or other contaminants into the gas line, use a 3-stage

coalescing filtration system, such as the Eliminizer filter kit (part number 128647) available from

Hypertherm distributors. A 3-stage filtering system works as shown below toclean contaminants

from the gas supply.

The filtering system should be installed between the quick-disconnect coupler and the power

supply.

80 – 100 psi (5.5 – 6.9 bar) gas supply

(maximum 135 psi or 9.3 bar) with a flow

rate of at least 350 scfh (165.2 l/min). The

recommended flow rate and pressure is

360 scfh @ 90 psi (170 l/min @ 6.2 bar).

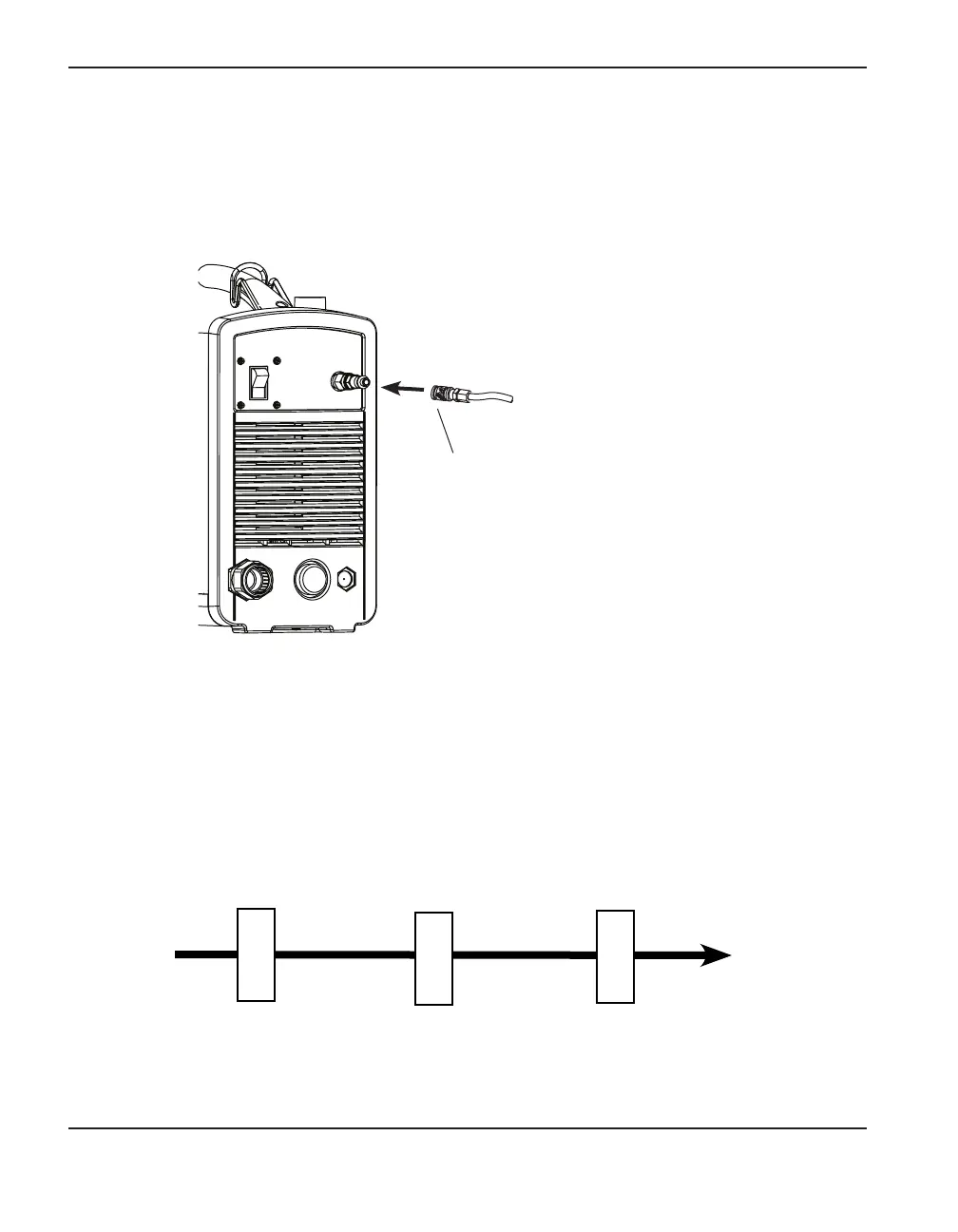

Connect the gas supply

Connect the gas supply to the power supply using an inert-gas hose with a 3/8 inch (9.5mm)

internal diameter and a 1/4NPT quick-disconnect coupler, or a 1/4 NPT x G-1/4 BSPP (CE units)

quick-disconnect coupler.

Loading...

Loading...