MAINTENANCE AND REPAIR

5-10 powermax

45

Operator Manual

TP 19

W

-

+

-

+

TP 18

R

TP 17

B

192 VDC

192 VDC

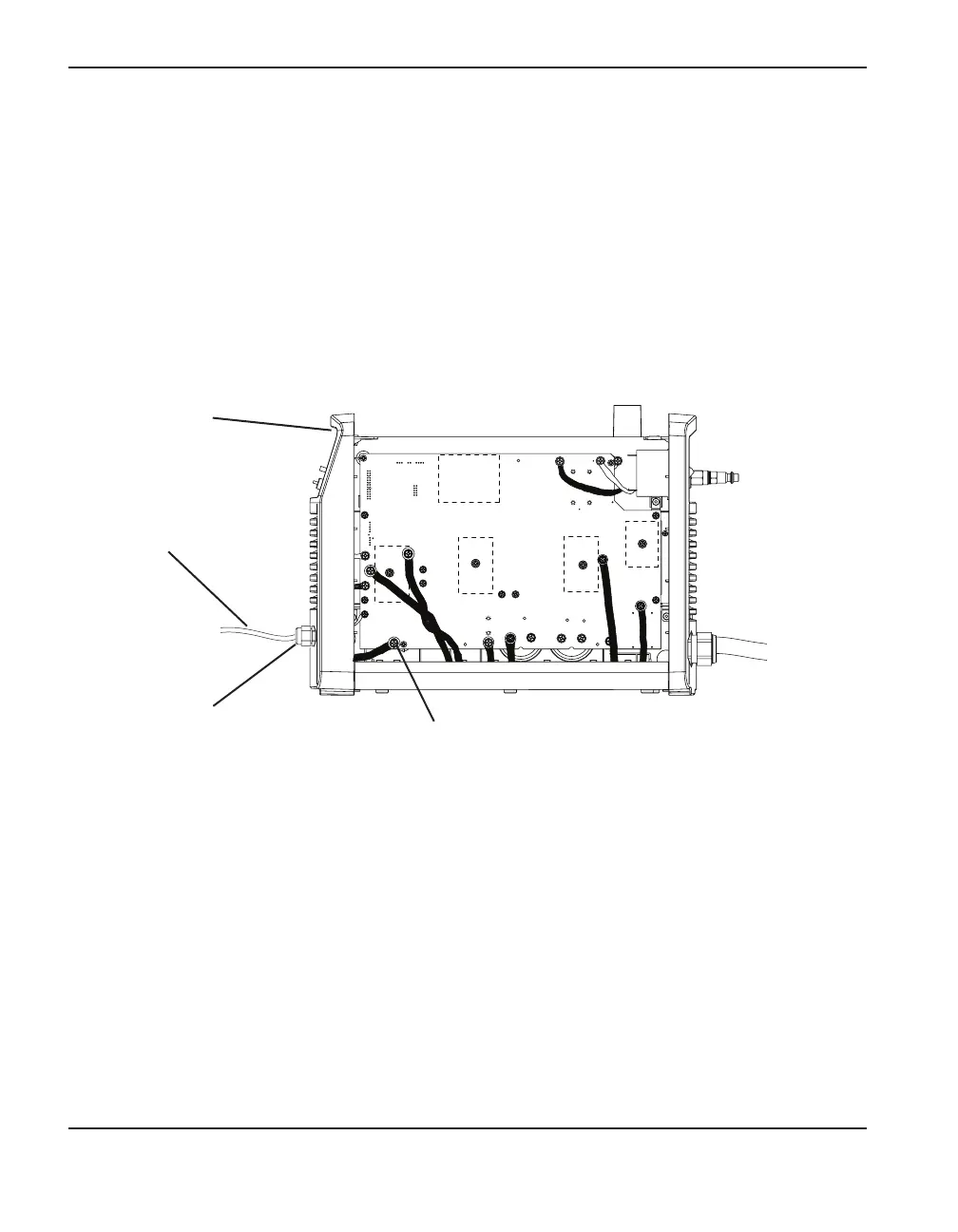

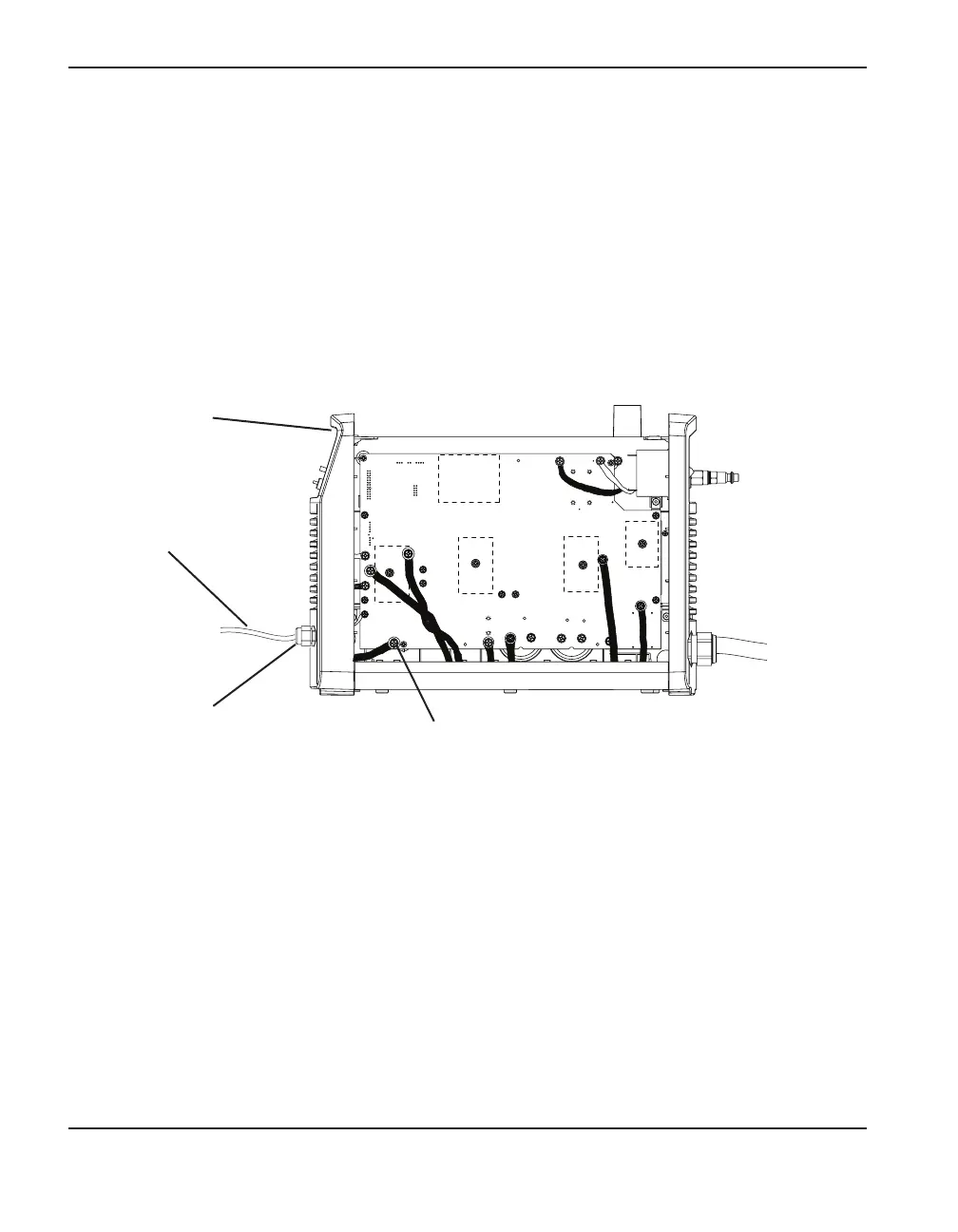

Replace the work lead (CSA and CE)

1. Turn OFF the power, disconnect the power cord, and disconnect the gas supply.

2. Remove the cover from the power supply and remove the Mylar barrier from in front of the

power board.

3. Remove the screw from J21 (also labeled “work lead”) on the power board that attaches the

lead to the board. Set the screw aside.

Work lead

Work lead connection to

power board (J21)

Front panel

Strain relief

4. Gently tilt the front panel away from the power supply. From the inside of the panel, unscrew the

nut that secures the strain relief to the endcap.

5. Thread the connector end of the new work lead through the front panel and fit the strain relief

into the hole in the panel.

6. Slide the nut over the work lead’s connector. Gently tilt the front panel away from the power

supply and screw the nut onto the strain relief.

7. Attach the work lead to the power board at J21 using the screw that you removed earlier. The

torque setting for this connection is 20 inch-pounds (23.4 kg cm)

8. Realign the front panel.

Loading...

Loading...