OPERATION

4-16 powermax

45

Operator Manual

Cause

The torch is too low.

The torch is too high.

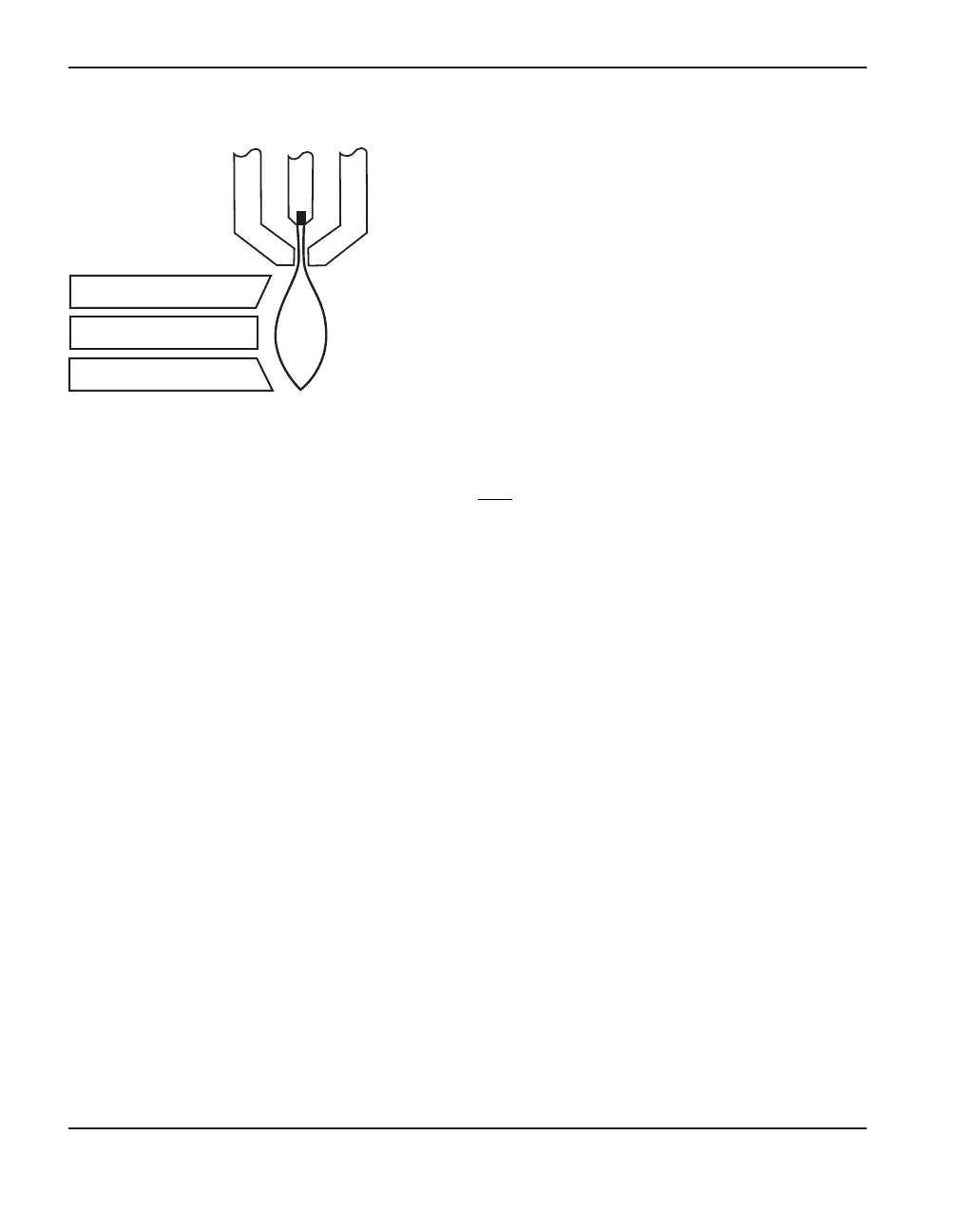

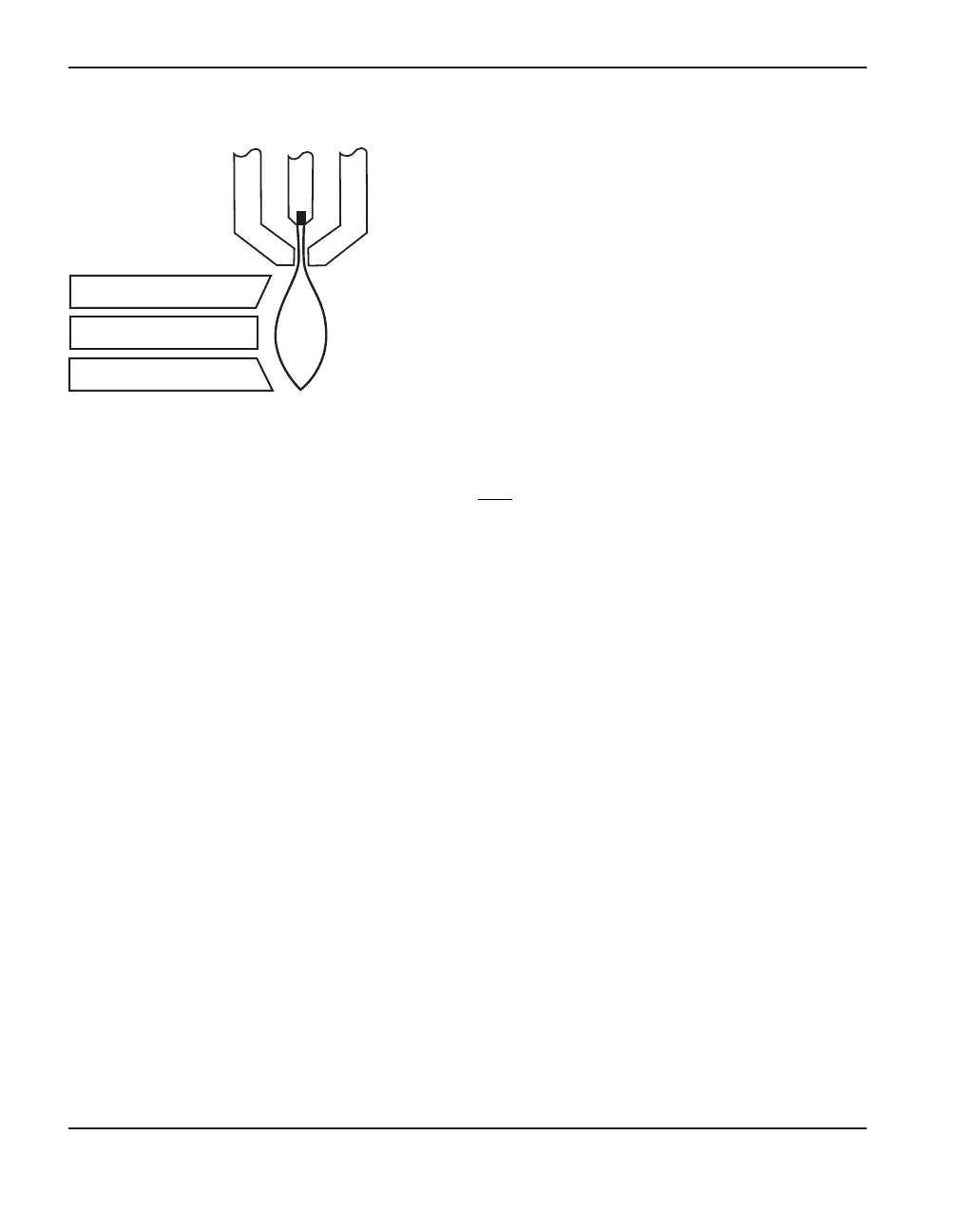

Square cut

\

Solution

Raise the torch; or if you are using a

torch height control, increase the arc

voltage.

Lower the torch; or if you are using

a torch height control, decrease arc

voltage.

Positive cut angle

Negative cut angle

Problem

Notes: The squarest cut angle will be on the right side with respect to the forward

motion of the torch. The left side will always have some degree of bevel.

To determine whether a cut-angle problem is being caused by the plasma system or the drive

system, make a test cut and measure the angle of each side. Next, rotate the torch 90° in its

holder and repeat the process. If the angles are the same in both tests, the problem is in the

drive system.

If a cut-angle problem persists after “mechanical causes” have been eliminated (see the previous

page, Ensure the torch and table are set up correctly), check the torch-to-work distance, especially

if the cut angles are all positive or all negative. Also consider the material being cut: if the metal is

magnetized or hardened, you are more likely to experience cut angle problems.

Dross

Some amount of dross will always be present when cutting with air plasma. However, you can

minimize the amount and type of dross by adjusting your system correctly for your application.

Dross appears on the top edge of both pieces of the plate when the the torch is too low (or voltage

is too high, if using a torch height control). Adjust the torch or the voltage in small increments (5

volts or less) until the dross is reduced.

Low-speed dross forms when the torch’s cutting speed is too slow and the arc shoots ahead. It

forms as a heavy, bubbly deposit at the bottom of the cut and can be removed easily. Increase the

speed to reduce this type of dross.

Loading...

Loading...