66 - 4

Powershift Gearbox

Pressure and Flow Testing, cont’d

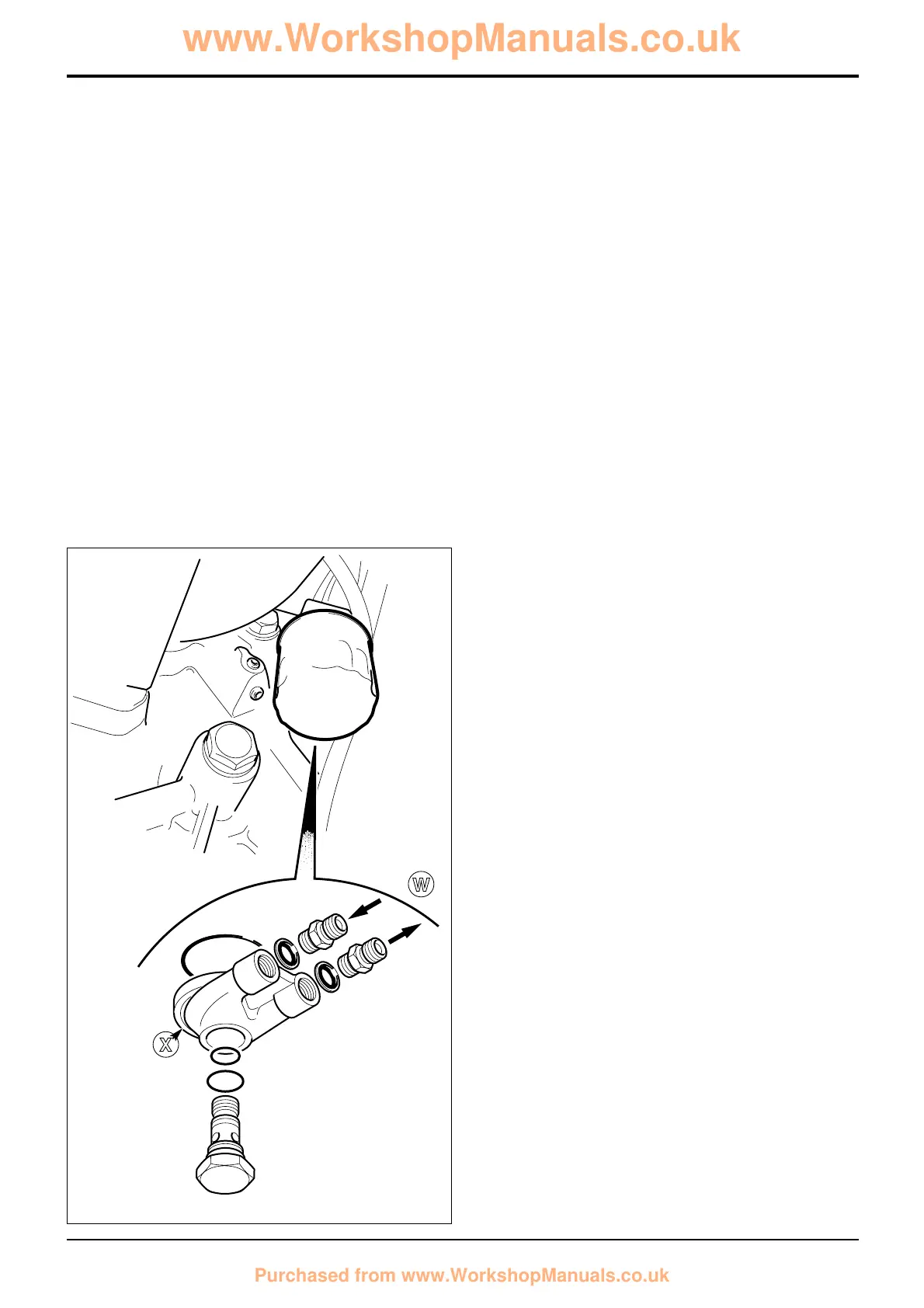

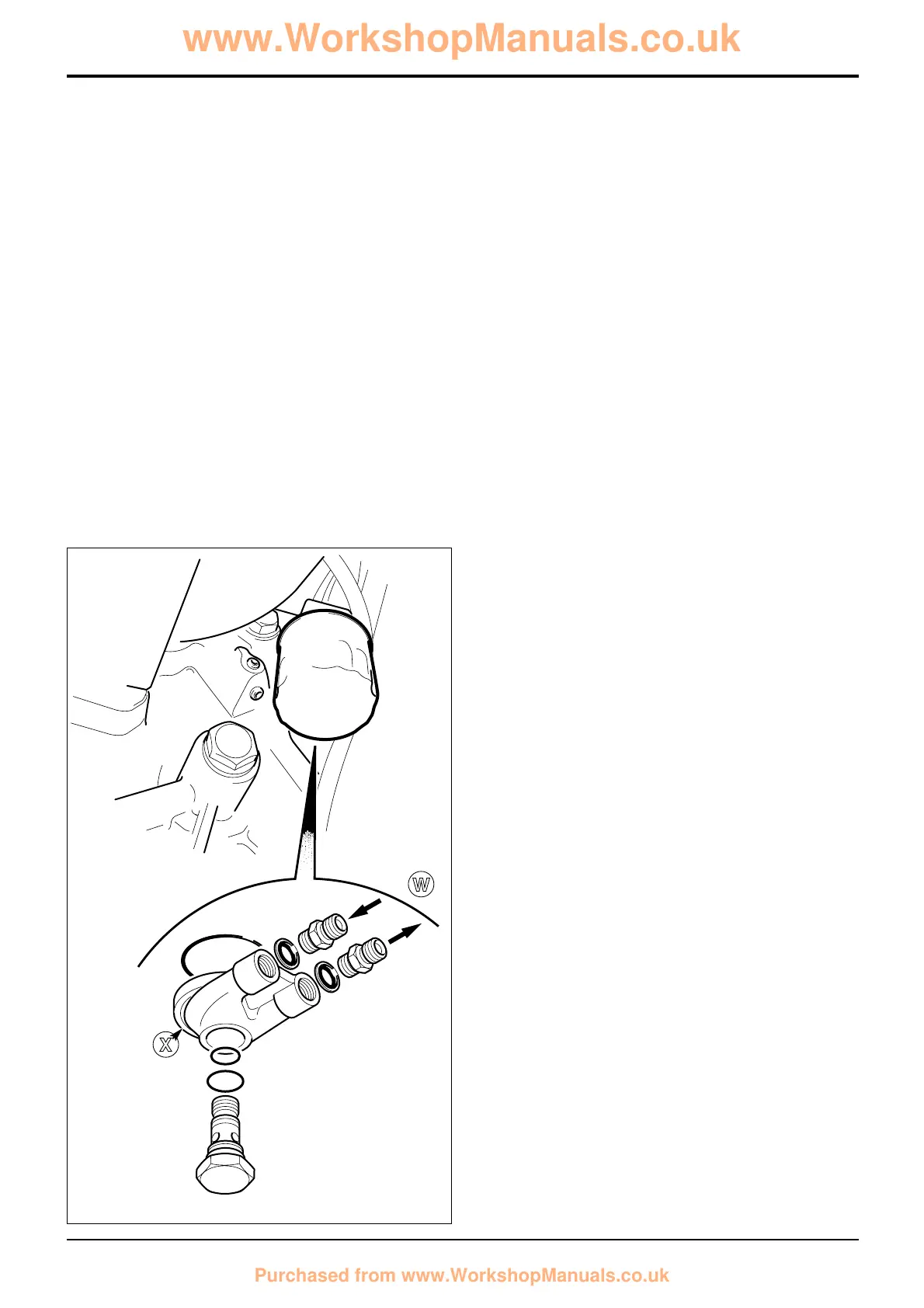

Pump Flow

1 Stop engine, remove the gearbox oil filter and fit

adapter X (460/15708) into the gearbox casing.

Connect flowmeter W (892/00268).

2 Start engine and run at 1000 rev/min. With the

transmission in neutral the flowmeter will show the

Pump Flow which should be as shown in Technical

Data. A low reading indicates a worn pump or blocked

suction strainer.

3 Repeat step 2 and note gauge readings with engine

running at 2000 rev/min.

4 Stop engine and remove test adapters, refit filter.

Mainline Pressure

1 Stop engine, connect a 0-20 bar (0-300 lbf/in

2

) pressure

gauge to test connector A.

2 Start engine and run at 1000 rev/min. With the

transmission in neutral the pressure gauge will show

the Main Line Pressure which should be as shown in

Technical Data. A low reading can be caused by either

a faulty pressure maintenance valve or a worn pump. A

high or low reading may indicate a faulty pressure

maintenance valve.

3 Repeat step 2, with engine running at 2000 rev/min

note gauge readings which should be as shown in

Technical Data.

4 Stop engine and remove test gauge.

Converter In Pressure

Note that the converter in pressure is affected by the torque

converter relief valve operation. Before carrying out tests

check the operation of the relief valve (see Converter Relief

(Safety) Valve Pressure).

1 Stop engine, connect a 0-20 bar (0-300 lbf/in

2

) pressure

gauge to test point B.

2 Start the engine and run at 1000 rev/min. With the

transmission in neutral the pressure gauge will show

Converter In Pressure which should be as shown in

Technical Data. A high or low reading could indicate a

faulty converter relief valve.

3 Remove pressure test gauge.

Section F

Transmission

9803/3280

Section F

66 - 4

Issue 1

Service Procedures

Loading...

Loading...