Section J - Tracks

Track Repair

Recommended Repair Procedures

J-27 J-27

9803-9570-4

Track Repair

Recommended Repair Procedures

Minor cuts which occur between the lugs can be repaired

with a suitable repair kit. Cuts no longer than 30mm and no

deeper than 10mm do not need to be repaired. Cuts

beyond these dimensions should be repaired as detailed.

Note, if steel is evident (irrespective of cut size), then a

repair should be completed to prevent oxidation (rusting)

and subsequent long term damage.

Specialist rubber compounds for cold vulcanisation can be

purchased from various outlets. The procedures below

describe typical good practice repair procedures. Always

check the manufacturer's instructions.

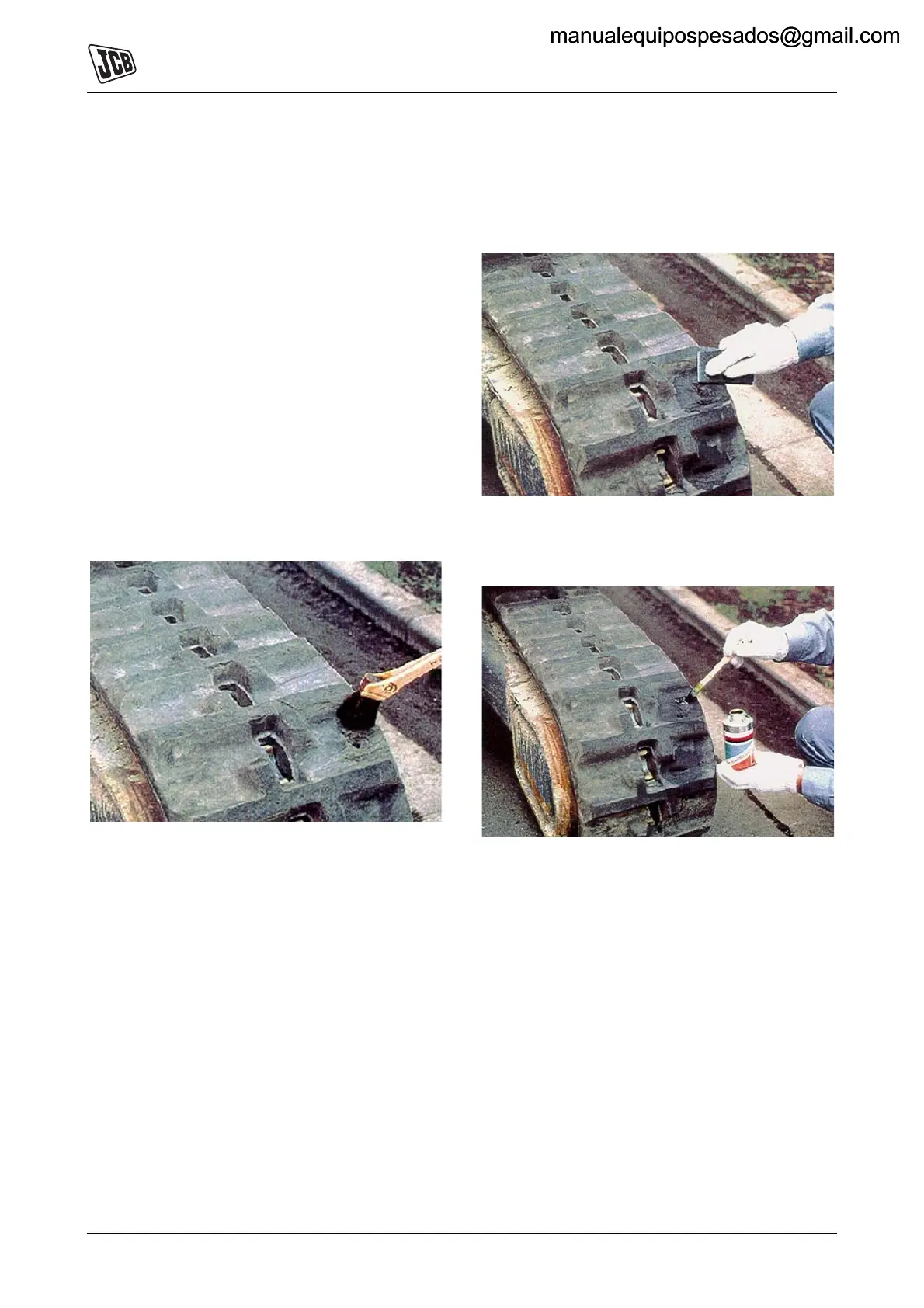

1 Clean the cut thoroughly to ensure correct adhesion

of the bonding agents. Use a brush or compressed

air. If oil is evident, a cleaning solution should be

used, make sure the area is dry.

Fig 1.

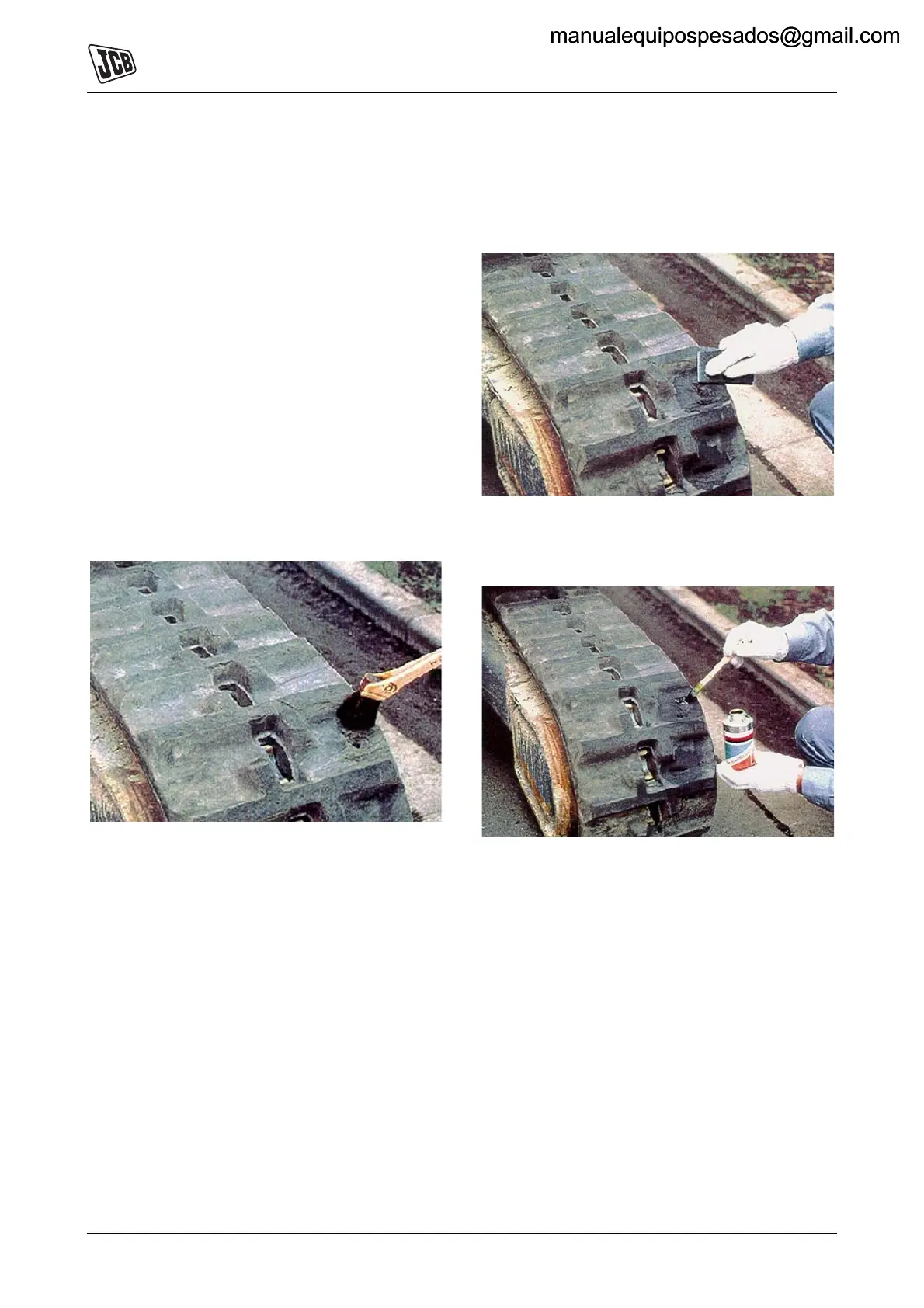

2 The area in and around the cut should be 'roughened'

to ensure good bonding adhesion. Use sand paper or

a clean wire brush. Make sure that the area is

roughened approximately 30 to 40 mm wider than the

cut. Clean the area using a suitable air compressor.

Fig 2.

3 Apply the adhesive.

Fig 3.

4 Mix the rubber compound. Note, the repair rubber is

usually supplied as two separate compounds which

are mixed together in equal quantities. Follow the

manufacturers instructions.

manualequipospesados@gmail.commanualequipospesados@gmail.com

Loading...

Loading...