-

97

-

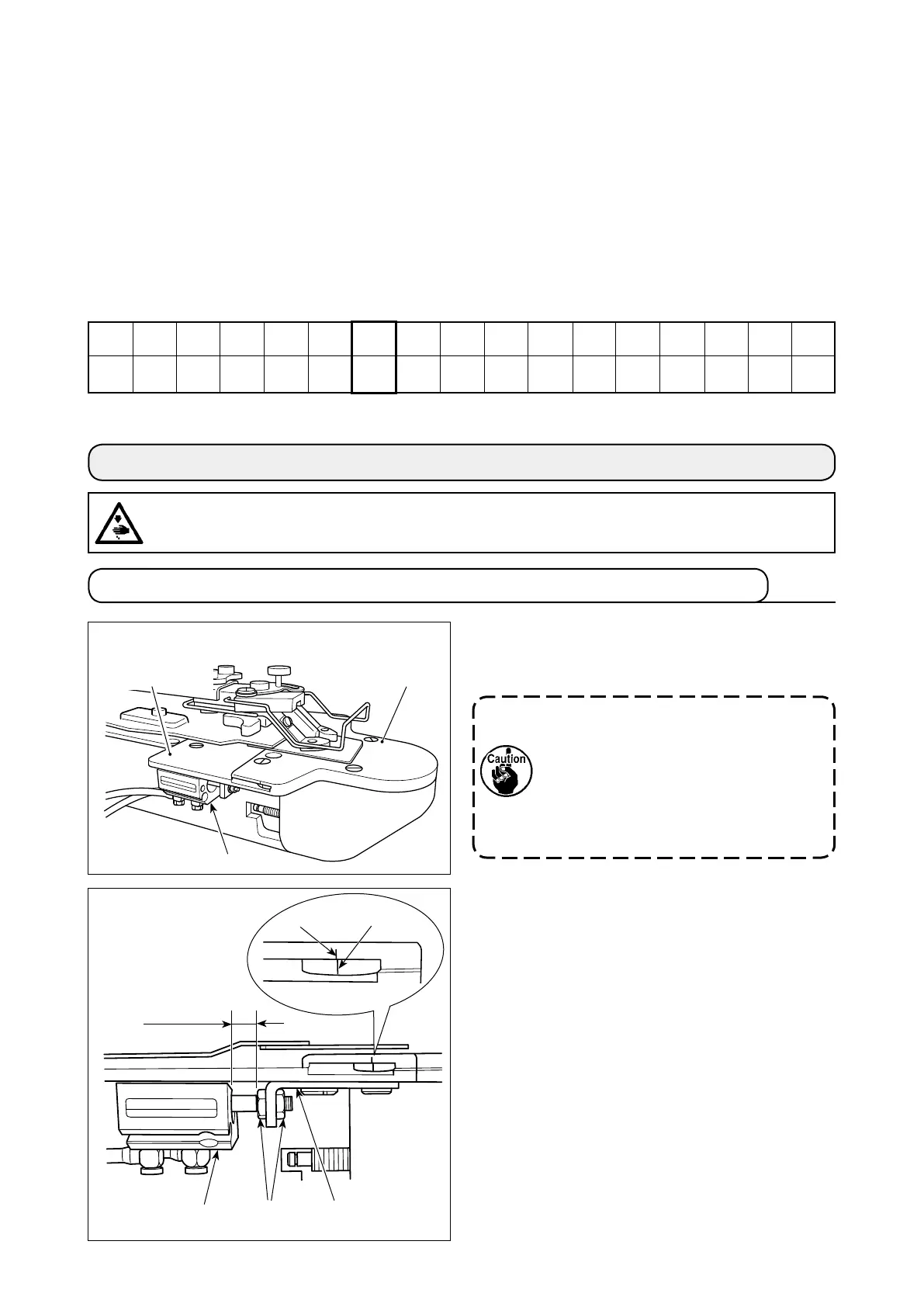

3-1. Adjusting the knife for the shorter thread remaining thread trimmer

3. ADJUSTMENT OF THE SEWING MACHINE

When the compressed air is supplied, shorter-thread

remaining thread trimmer cylinder

moves forward.

This is the initial position.

In the case cylinder

does not move

forward when the compressed air is sup-

plied, the piping connection is not cor-

rect.

Be aware mechanical failures such

as needle breakage can occur, if sewing

is carried out without correcting the con-

nection of piping.

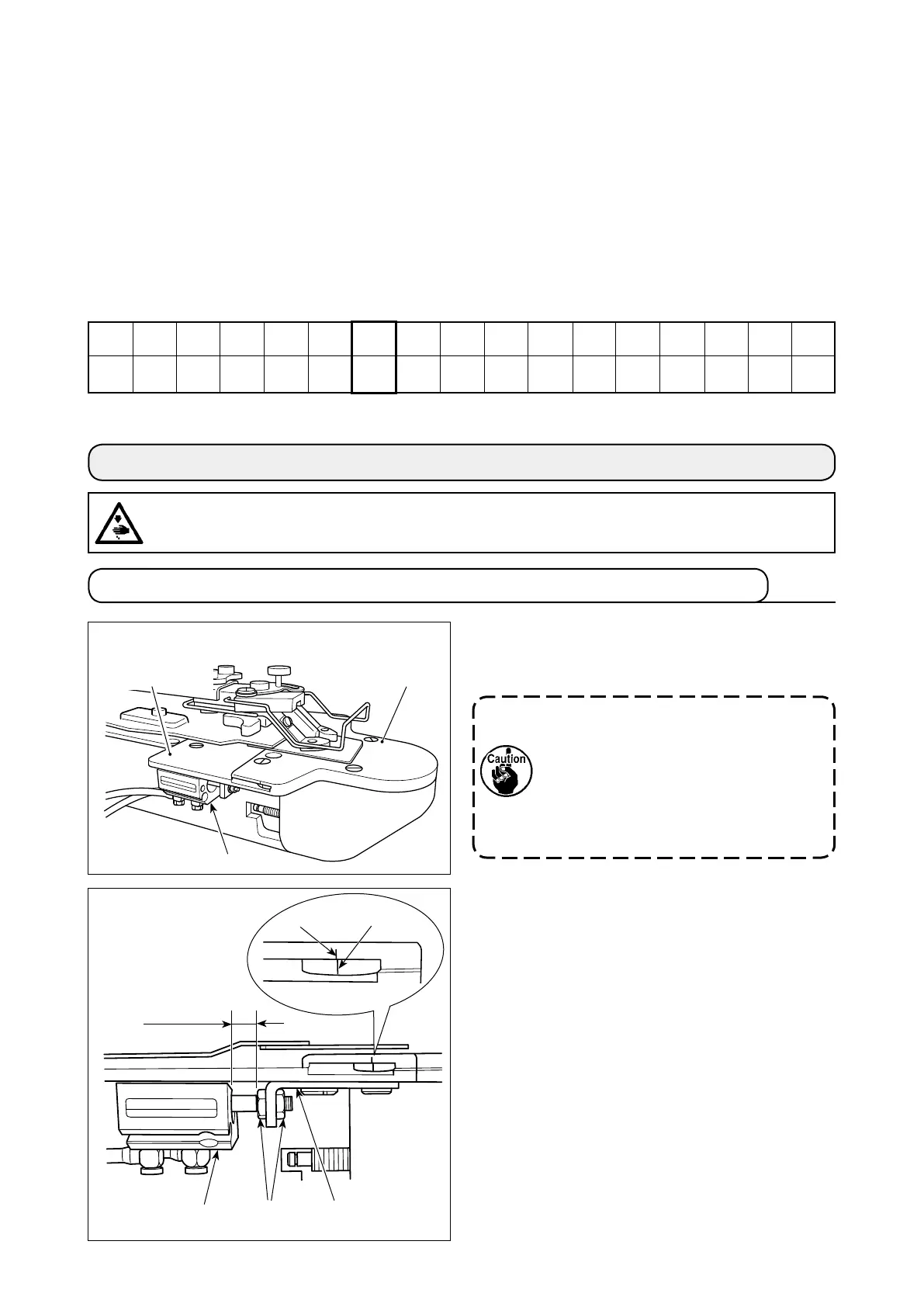

At the aforementioned initial position, loosen the nut

and adjust the cylinder guide

so that the notch

mark

in the knife base is aligned with the notch

mark

on the moving knife base.

Knife base

Throat plate asm.

(7.5mm)

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

(2) Selection of the sewing pattern and the sewing width

Selection of the sewing pattern is the same as that of the LK-1900B.

When the distance between holes of the button used does not t the standard sewing width of the sew-

ing pattern No., adjust the sewing width by enlarging/reducing the sewing width.

The way of enlarging/reducing is the same as that of the LK-1900B. Refer to the table given below for

the scale for enlargement/reduction in terms of the sewing width.

After changing the sewing pattern No. and the sewing width, make sure of the needle entry point.

As for the way of conrmation, refer to the

"I.5-4. Checking the contour of a sewing pattern"p.20

in the

instruction manual for the LK-1900B.

Table of XY scale in terms of the sewing width

X•Y

(mm)

% 71 76 82 88 94 100 106 118 126 132 138 153 165 176 182 188

2.4 2.6 2.8 3.0 3.2 3.4 3.6 4.0 4.3 4.5 4.7 5.2 5.6 6.0 6.2 6.4

Loading...

Loading...