42

6-8. Cautions in operation

(1) When the error indicator lamp lights up, be sure to check the cause of trouble and take a proper correc-

tive measure.

(2) Do not draw, by hand, the material being sewn during sewing. Doing so will cause the needle shift from

the correct position. If the needle moves from the correct position, press READY key

two times.

This will return the needle to the normal origin.

(3) Do not turn OFF the power in a state that the needle is lowered. The presser comes down and the wiper

interferes with needle. As a result, there is a danger of needle breakage or the like.

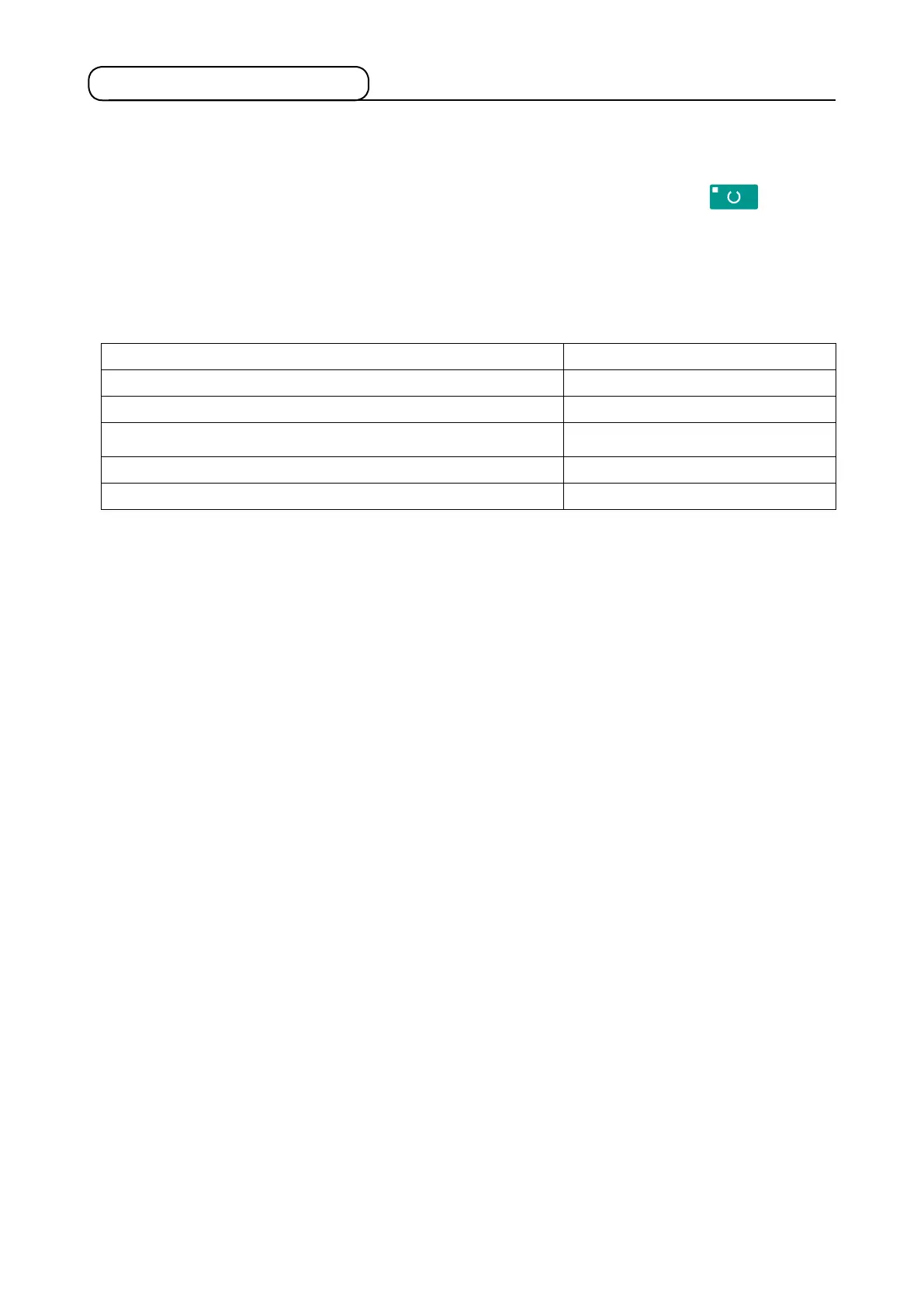

Reference for the sewing speed to be applied

* To prevent the thread breakage due to the needle heat, set the sewing speed referring to the above ta-

ble in accordance with the sewing conditions.

* For sewing the foundation or the like, lower the height of the needle bar to prevent the stitch skipping.

(Refer to the item

"I.7-1. Adjusting the height of the needle bar" p.44

).

Sewn product / thread / needle Head type / Sewing speed

8-layered denim / Cotton thread #50 / DPx5 #16 S (Standard) / 3,200 sti/min

8-layered woolen gabardine / Polyester lament #50 / DPx5 #14 S (Standard) / 2,300 sti/min

8-layered denim / Cotton thread #20 / DPx17 #19

H (Heavy-weight material)/3,200 sti/min,

W (Double-capacity hook)/2,700 sti/min

Overlapped sewing of 6 x 12-layered denim / Cotton thread #20 / DPx17 #19

H (Heavy-weight material) / 2,500 sti/min

Tricot + shoulder strap (3 + 1) layered section / Polyester spun #60 / DPx5 #11 F (Foundation) / 2,000 sti/min

Loading...

Loading...