48

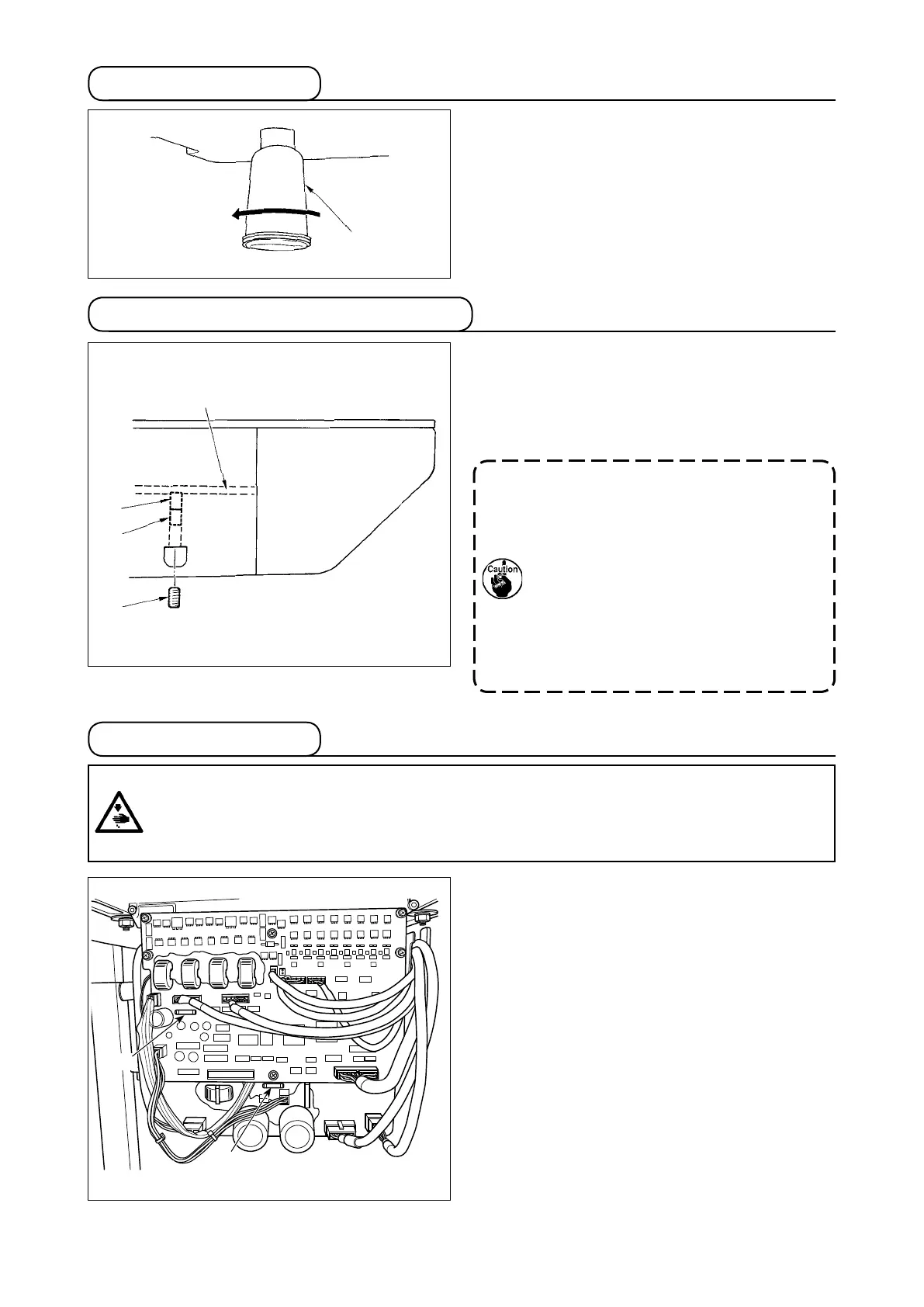

7-8. Amount of oil supplied to the hook

1) Loosen setscrew

and remove setscrew

.

2) When screwing in adjustment screw

, the

amount of oil of oil pipe, left

can be reduced.

3) After the adjustment, screw in setscrew

and

x it.

1. The state of standard delivery is the po-

sition where

is lightly screwed in and

returned by 4 turns.

2. When reducing the amount of oil, do

not screw in the screw at once. Ob-

serve the state for approximately half a

day at the position where

is screwed

in and returned by 2 turns. If reducing

is excessive, worn-out of the hook will

result.

When polyethylene oiler

becomes lled with oil,

remove polyethylene oiler

and drain the oil.

7-7. Draining waste oil

7-9. Replacing the fuse

The machine uses the following two fuses :

MAIN PWB

For pulse motor power supply protection

5A (time-lag fuse)

SDC PWB

For control power supply protection

2A (fast-blow type fuse)

DANGER :

1. To avoid electrical shock hazards, turn OFF the power and open the control box cover after about

ve minutes have passed.

2. Open the control box cover after turning OFF the power without fail. Then, replace with a new fuse

with the specied capacity.