45

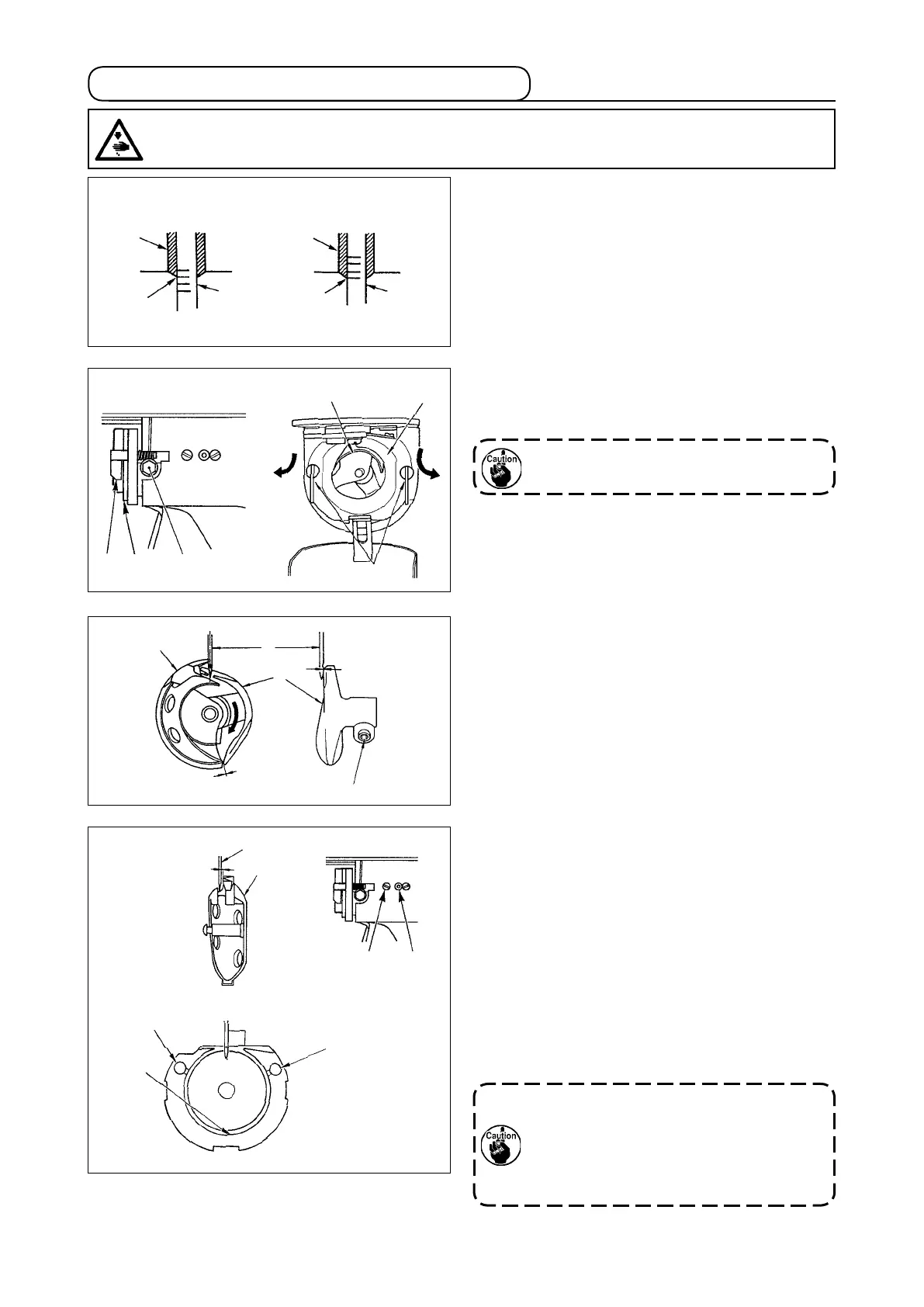

1) Turn the handwheel by hand. When needle bar

has gone up, adjust so that lower marker line

engraved on the needle bar aligns with the

bottom end of the needle bar bushing

, lower.

2) Loosen setscrew

in the driver. Open inner

hook pressers

to the right and left, and re-

move inner hook presser

.

At this time, be careful not to let inner

hook

come off and fall.

7-2. Adjusting the needle-to-shuttle relation

Relation between needle and engraved lines

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

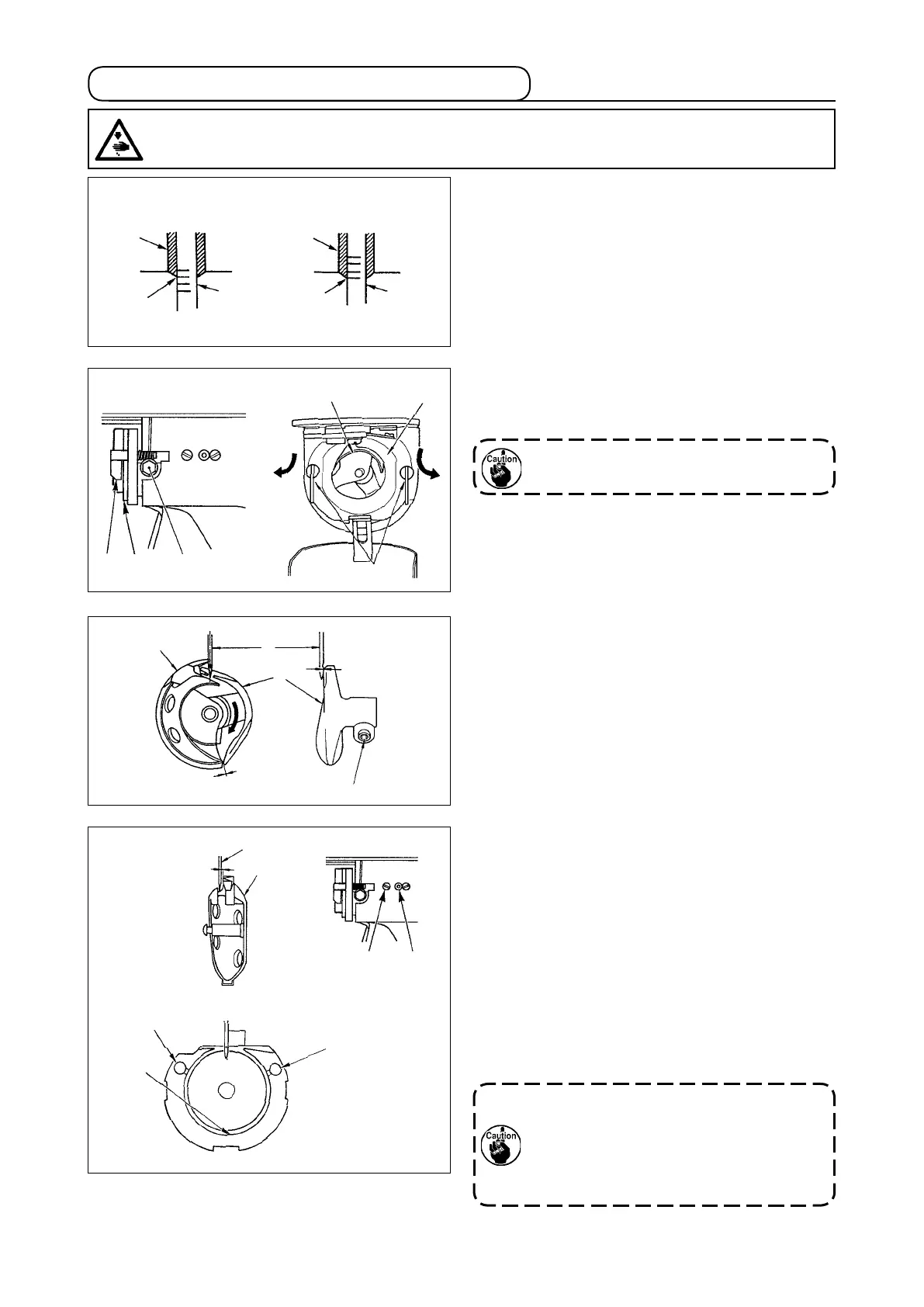

3)

Adjust so that the blade point of inner hook

aligns

with the center of needle

, and that a clearance

of 0 mm is provided between the front end of the

driver and the needle as the front end face of driver

receives the needle to prevent the needle from

being bent. Then tighten setscrew

of the driver.

4) Loosen setscrew

of the shuttle, and adjust

the longitudinal position of the shuttle. To do this

adjustment, turn shuttle race adjusting shaft

clockwise or counterclockwise to provide a 0.05

to 0.1 mm clearance between needle

and the

blade point of inner hook

.

5) After adjusting the longitudinal position of the

shuttle, further adjust to provide a 7.5 mm clear-

ance between the needle and the shuttle by

adjusting the rotating direction. Then tighten set-

screw

of the shuttle.

If the sewing machine is left unused for a

long time, or after clearing the area sur-

rounding the hook section, apply a little

quantity of oil to race section

and felt

before using the sewing machine.

0.05 to 0.1 mm

7.5 mm

0 mm

0 mm

Loading...

Loading...