ISG 2000 User’s Guide

26 Equipment Rack Mounting

Equipment Rack Mounting

The ISG 2000 comes with accessories for mounting the device in a standard 19-inch

equipment rack.

Equipment Rack Installation Guidelines

The location of the chassis, the layout of the equipment rack, and the security of

your wiring room are crucial for proper system operation. Use the following

guidelines while configuring your equipment rack.

Enclosed racks must have adequate ventilation. Such ventilation requires

louvered sides and a fan to provide cooling air.

When mounting a chassis in an open rack, be sure that the rack frame does not

block the intake or exhaust ports. If you install the chassis on slides, check the

position of the chassis when it is seated all the way into the rack.

In an enclosed rack with a ventilation fan in the top, equipment higher in the

rack can draw heat from the lower devices. Always provide adequate ventilation

for equipment at the bottom of the rack.

Baffles can isolate exhaust air from intake air. The best placement of the baffles

depends on the airflow patterns in the rack.

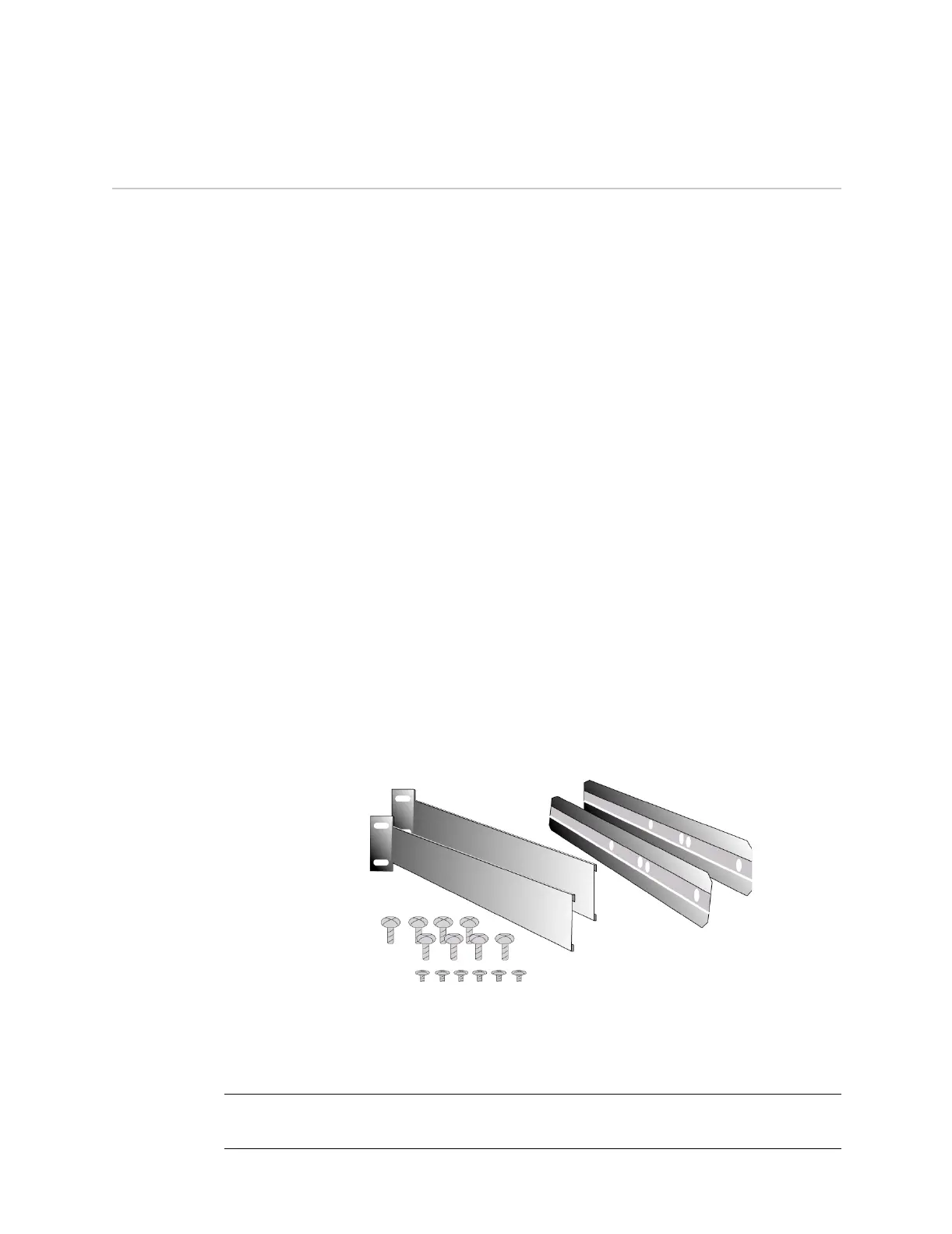

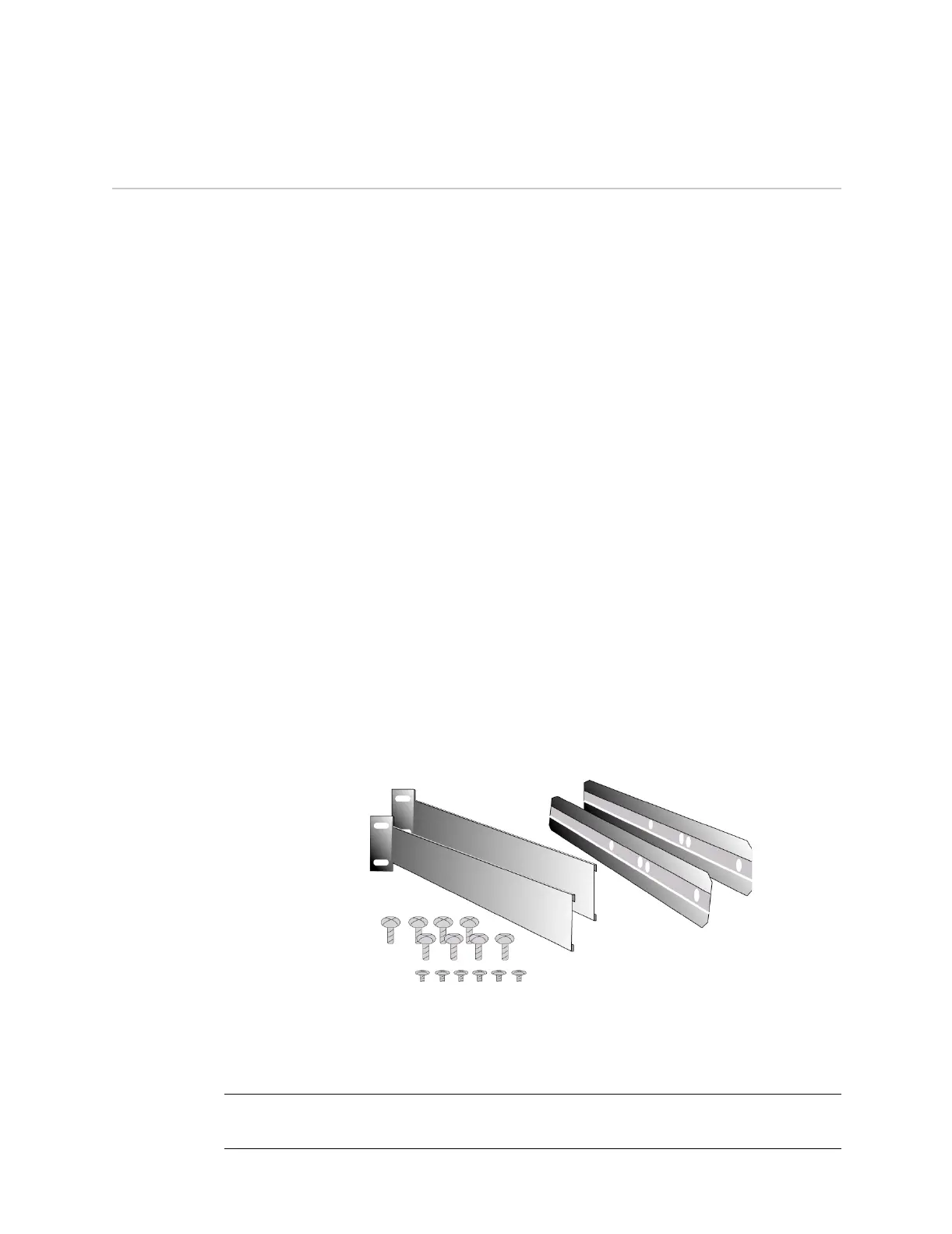

Equipment Rack Accessories and Required Tools

Rack mounting requires the following accessories and tools:

1 Phillips-head screwdriver (not provided)

4 screws to match the rack (if the thread size of the screws provided in the ISG

2000 product package do not fit the thread size of the rack)

The included rear slide mount kit (for the rear-and-front-mount method)

Figure 12: Rack Mount Kit

There are two ways to rack mount the ISG 2000:

Rear-and-front mount

Mid-mount

NOTE: Juniper Networks recommends using the rear-and-front rack mount when the

equipment rack supports it. Do not attempt to front-mount the ISG 2000.

Loading...

Loading...