Service Information

4-2

• Use dry nitrogen gas to clean dust off the board if nec-

essary.

4.2.2 Soldering precautions

Should it become necessary to use solder on the circuit

board, observe the following precautions:

• Use an OA-based (organic activated) flux, and take care

not to spread the flux to other areas of the circuit board.

• Remove the flux from the work areas when the repair

has been completed. Use pure water along with clean

cotton swabs or a clean, soft brush to remove the flux.

• Once the flux has been removed, swab only the repaired

area with methanol, then blow dry the board with dry

nitrogen gas.

• After cleaning, the card should be allowed to dry in a

50

°

C low-humidity environment for several hours be-

fore use.

4.3 Performance verification

The following paragraphs discuss performance verification

procedures for the Model 2001-TCSCAN, including reference

junction, path resistance, contact potential, and isolation.

CAUTION

Contamination will degrade the perfor-

mance of the card. To avoid contamina-

tion, always grasp the card by the side

edges and covers. Do not touch connec-

tor insulators, board surfaces, or com-

ponents.

NOTE

Failure of any performance verification

test may indicate that the scanner card is

contaminated. See paragraph 4.2 for infor-

mation on cleaning the card.

4.3.1 Environmental conditions

All verification measurements should be made at an ambient

temperature between 18

°

and 28

°

C, and at a relative humid-

ity of less than 70%.

4.3.2 Recommended equipment

Table 4-1 summarizes the equipment needed for performance

verification and calibration (covered in paragraph 4.4). The

Model 2001 DMM is used in the procedures. However, you

can also use the Model 2000, 2002, or 2010. If using the Mod-

el 2000 or 2010, you may have to alter some procedure steps

slightly.

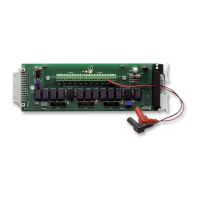

4.3.3 Scanner card connections

Jumper wires or connecting cables can simply be hard-wired

directly to the screw terminals of the Model 2001-TCSCAN.

Detailed connection information is provided in Section 2.

4.3.4 Reference junction test

This procedure verifies that the Model 2001-TCSCAN card

is operating within its temperature specification. The Model

2001 Multimeter is used to close Channel 1 of the card.

A second DMM must be used to make the voltage measure-

ments because the Model 2001 will not meet specifications

with the cover removed.

1. Remove the top shield from the Model 2001-TCSCAN,

and install it in the first Model 2001. Remove the Model

2001 cover to allow access to the card (see paragraph

4.7.2).

2. Turn on the second Model 2001, and set it to the

200mVDC range. Short the test lead ends together. Zero

the multimeter after the thermals have stabilized (one

hour if from cold-start).

3. Set up the test equipment as shown in Figure 4-1, and let

it warm up one hour. Be sure to protect the card from air

drafts. Use a probe with a specified accuracy of

±

0.005

°

C. The combination of the probe and reference

thermometer should be accurate to

±

0.03

°

C.

Loading...

Loading...