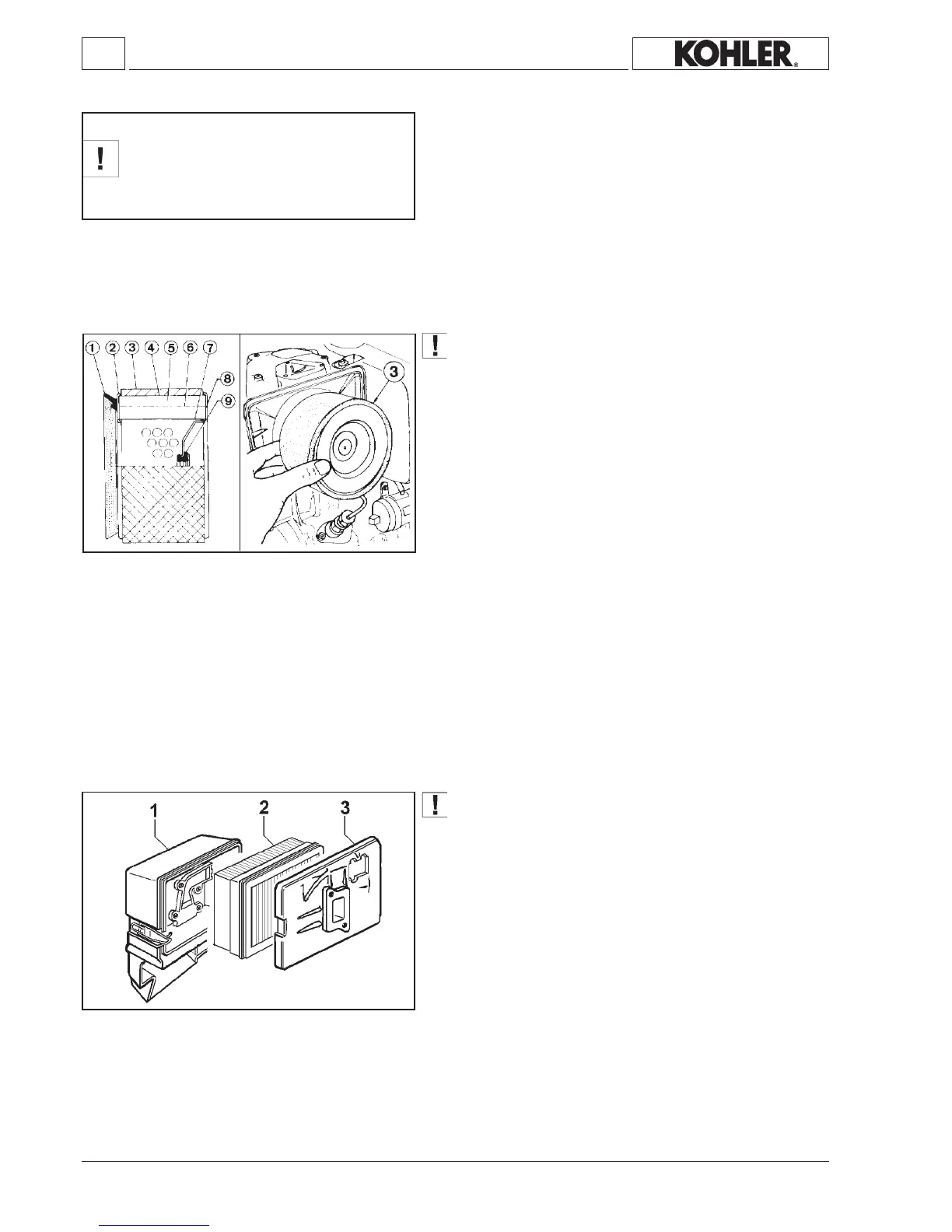

1 2

3

8

- 20 -

DISASSEMBLY/REASSEMBLY

WARNINGS!

During repair operations, when

using compressed air, wear eye

protection.

DISASSEMBLY AND REASSEMBLY

Besides disassembly and reassembly operations this chapter also

includes checking and setting specications, dimensions, repair and

operating instructions.Always use original KOHLER spare parts for

repairoperations.

Clean the ltering element with air blast. Air must be blown

frominsidetooutsidethecartridgeatadistanceofatleast15

cmfromthepaper.

Lightly and repeatedly tap the element on a hard surface to

eliminateallexcessdirt.

Cartridgecomponents:

1Seal

2 Metallicbody

3 Polyurethaneprelter

4 outermesh

5Filtermedia

6 Blade

7 Insideenvelope

8 Metallicbody

9Innerseal

Cartridge characteristics:

mediaporosity7µm,usefullteringarea1960cm

2

.

Polyurethane pre-lter characteristic:

porosity60p.p.i.,frontarea207cm

2

.

Note: Pre-lter3canundergomaintenanceoperations;ifdirty,wash

withsoapand water and dry(maximum10 cleanings ).See

page18forcartridgereplacement.

Clean the ltering element with air blast. Air must be blown

frominsidetooutsidethecartridgeatadistanceofatleast15

cmfromthepaper.

Lightly and repeatedly tap the element on a hard surface to

eliminateallexcessdirt.Replaceifirreparablyclogged.

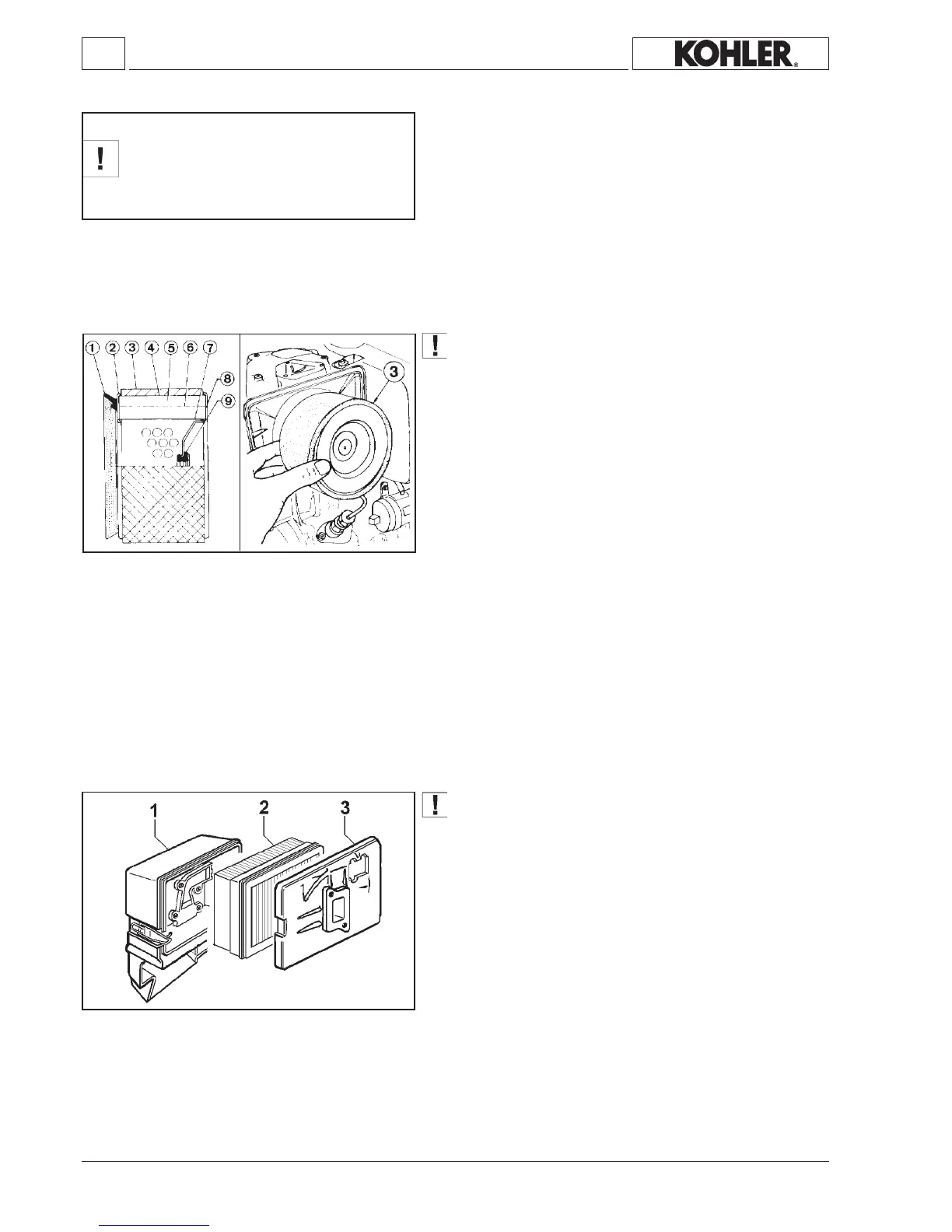

Cartridgecomponents:

1 Completecover

2Filteringmaterial

3Support

Characteristicsofthelteringmaterial:

paperporosity:3µm

lteringarea:4400cm²

outerringinopen-cellpolyurethane

Seepage18forthefrequencywithwhichthelteringmaterialmust

bechanged.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Dry air cleaner for KD 315 and KD 350

Dry air cleaner for KD 225

Loading...

Loading...