43 44

45

46

47

8

A

511.0÷70.0 01.0÷70.0 11.0÷530.0 11,0÷70,0

B

80.0÷40.0 80.0÷50.0 90.0÷050.0 90,0÷50,0

C

70.0÷30.0 570.0÷40.0 780.0÷030.0 70,0÷30,0

225

315 350-400 440

- 34 -

DISASSEMBLY/REASSEMBLY

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

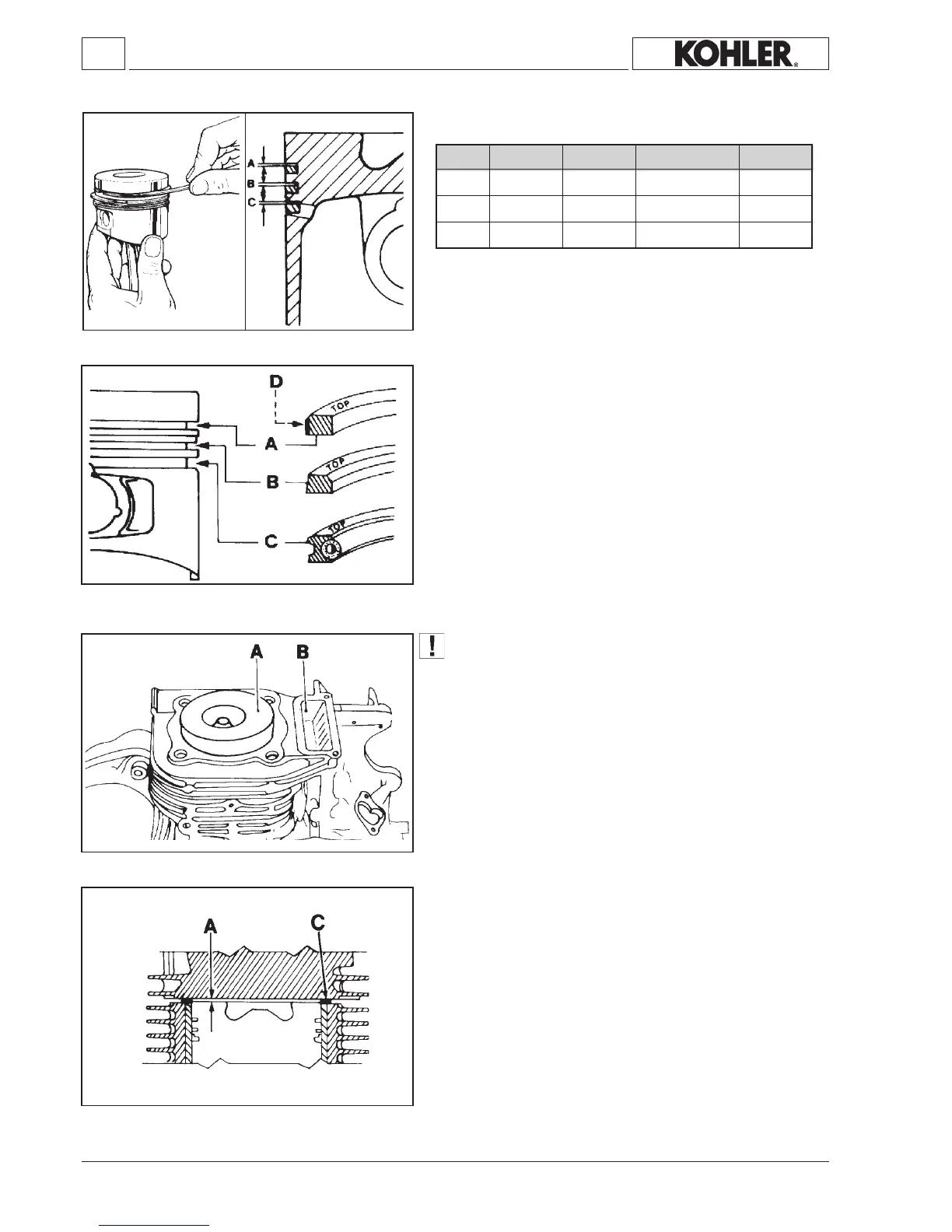

Piston rings, play between the slots (mm)

Replacethepistonorpistonringsifthevalueexceedsthemaximum

limit.

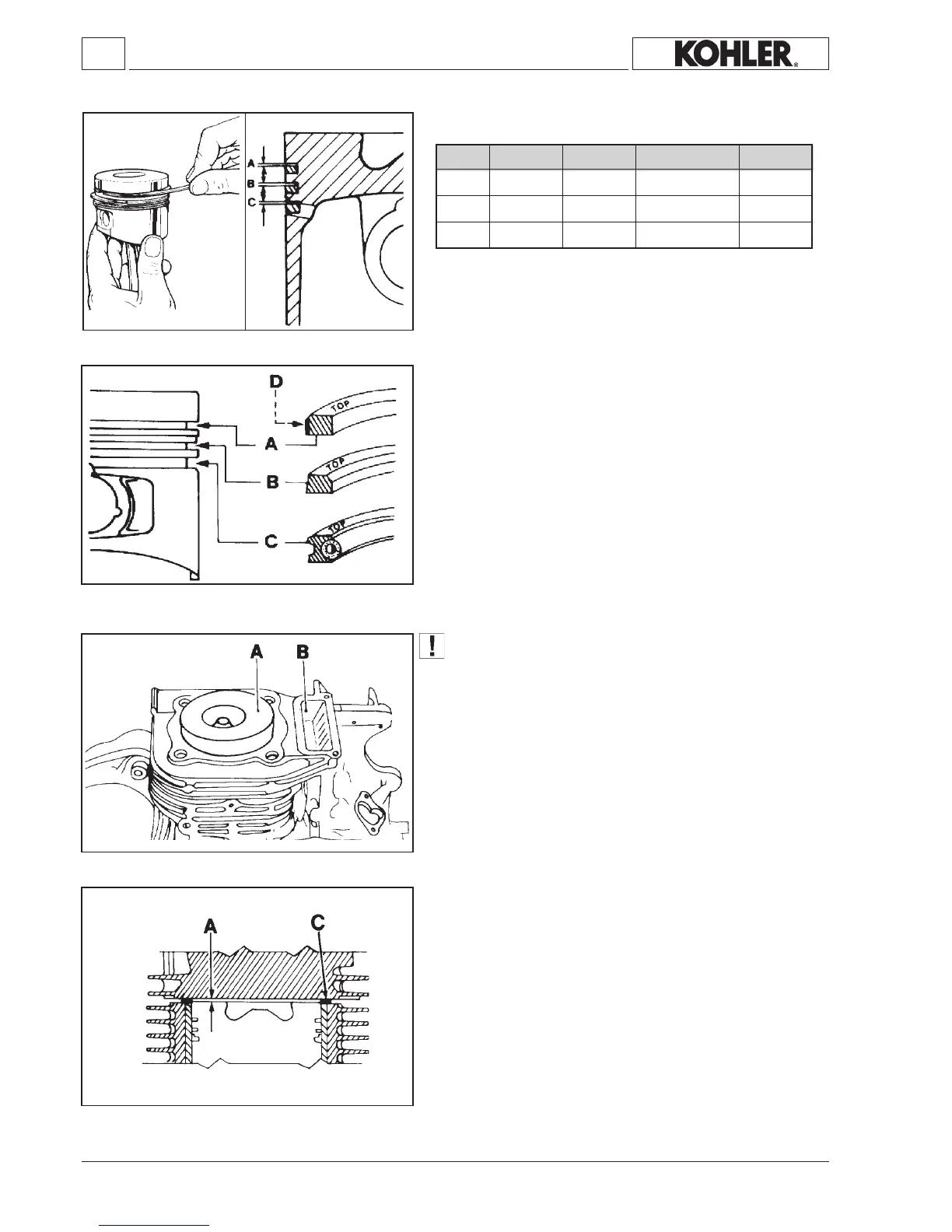

Piston rings, assembly order

A =1stChromiumplatedpistonring(nitridedfor225-350-400)

B =2ndpistonring(torsional)

C =3rdpistonring(oilscraper)(nitridedfor225-350-400)

D =Chromiumplatedzone

Note: Ifaword(top,orsomeotherword)iswrittenonthesurfaceof

apistonring,mountthatsurfaceupwards.

Beforeinsertingthepistonintothecylinder,oilandturnthepi-

stonringssothatthecutsarestaggered120°toeachother.

InKD350andKD225engines,thesecondpistonringisnot

torsional,whiletherstandthirdpistonringsdonothavechro-

miumplatedzonesbutarenitrided.

Lubricate the following parts with oil before mounting: the pi-

stonpin,thepiston,thecylinderandthebig-endbearing

Piston - Retting

Connect piston to connecting rod, lubricate piston pin and introduce

it into the piston/connecting rod assembly by exerting pressure with

yourthumb.

Fitbothpistonpincirclipsandcheckthattheyarewellseated.

When introducing both the connecting rod and the piston into the

cylindermakesurethatthelargercrownsurfaceA (ifcomparedtothe

combustionchamber)isonthesamesideasthepushrodopeningB.

Clearance

A =Clearance

C =Headgasket

Thethicknessofgasket Cdeterminestheclearance A,whichmustbe

0.45-0.55mmforKD315withinjectionpumpserialN°6590-259;itis

0.50-0.60mmwithinjectionpumpserialN°6590-281.

Theclearanceis0.45-0.55mmforKD225inallcases.

Theclearanceis0.50-0.60mmforKD350-400-440inallcases.

ForthecorrectthicknessofgasketCseetableing.49÷50.

There are gaskets with inner diameters oversized by 1 mm for KD

315andKD350,requiredifthecylindersareground.

Loading...

Loading...